Nonwoven PA6Recycling Hydrogen 02-04-2021 - Arhive

Nonwoven PA6Recycling Hydrogen

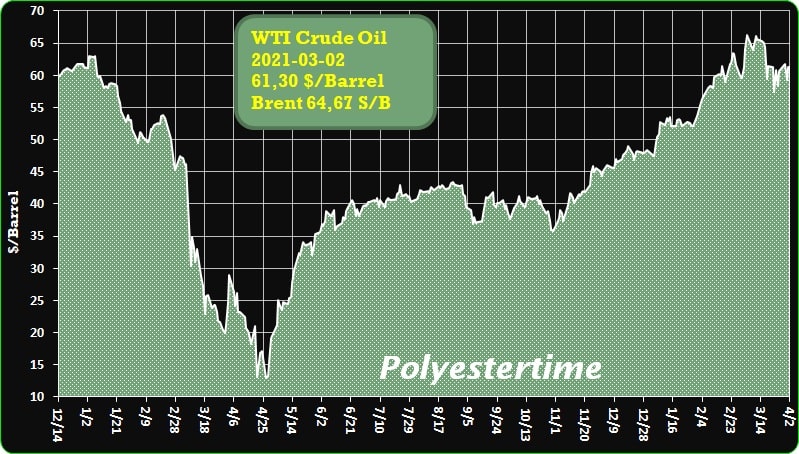

Crude Oil Prices Trend

-New production units and increased production capacity for engineering polymers

RadiciGroup High Performance Polymers strengthens its global presence with investments of over EUR 35 million: new plants in Mexico and China, expansion in Europe and North America

Investments of over EUR 35 million in business growth, sustainability and innovation. The RadiciGroup High Performance Polymers Business Area is adding significantly to its global production capacity with new construction and installations in North America, Europe and China.

“The High Performance Polymers business is highly strategic to our Group,” said Maurizio Radici, vice president and COO of RadiciGroup. “The business area is a network of production and sales units located throughout Europe, North America, South America and Asia that can meet the needs of both local and global customers with a complete, innovative and sustainable product offering. This is the reason we have decided to strengthen our presence even further by setting up new and more technologically advanced manufacturing facilities, so as to increase our overall production capacity and efficiency level worldwide.”

Production capacity has been increased by 20,000 tons/year in North America, namely, at Radici Plastics USA and Radici Plastics Mexico. In particular, a new site was inaugurated in Mexico, extending over an area of 20,000 square metres, which is needed to support current and future development.

In China, work has begun on the construction of a new 25,000-square metre plant that will boost production capacity by 30,000 tons/year. The total investment of almost EUR 20 million in Suxiang District Industrial Park, in the City of Suzhou, was made in light of expectations for strong growth in the High Performance Polymers business in the Asian region.

Maurizio Radici, Vice President and COO of RadiciGroup

-Bio2Bottle – The durable and biodegradable bio-plastic bottle

Fraunhofer Institute scientists conduct research with partners on reusable, biological plastics for storing cleaning agents and agricultural soil additives.

According to figures from the Federal Environment Agency, Germany alone produces around 6.28 million tons of plastic waste each year. Worldwide, the figure is around 400 million tons. If you then consider that a plastic bottle takes around 500 to 1,000 years to decompose, it quickly becomes clear how critical the situation has now become. Discussions in society and politics have therefore also led to the need to consider new goals in plastics development. The key word here is sustainability. More and more companies are making it a priority to avoid critical products and are increasingly aiming to produce recyclable, biodegradable products.

In the context of this increasing environmental awareness, the Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT is conducting research as part of the “Bio2Bottle” project together with four other partners. The researchers are working on bio-based plastics and bottles that meet high standards and are also biodegradable and recyclable. Currently available plastics made from renewable raw materials such as polylactic acid (PLA) are too permeable for storing cleaning agents or agricultural soil additives and do not meet all requirements. PLA is a lactic acid and bio-based polyester with superior mechanical strength – similar to polyethylene terephthalate (PET).

-Sipa Group, Plastic Technologies enter strategic partnership for PET packaging

The partnership is intended to help both companies to increase their visibility and create new business opportunities.

Plastic Technologies Inc. (PTI), a Holland, Ohio-based PET packaging research and development firm, and Italy-based PET packaging machinery specialist Sipa SpA have entered into a new strategic partnership agreement.

In a news release, Sipa officials said the partnership will “help both companies to increase their visibility and create new business opportunities.”

“Joining forces with Sipa makes perfect sense for PTI. We bring extensive knowledge in package development and material expertise to their capabilities’ portfolio,” said Thierry Fabozzi, PTI CEO. “This strong collaboration will also give PTI access to Sipa’s latest equipment and enable us to provide even better turnkey solutions for our brand-owner customers.”

-Loparex expands sustainable portfolio

Loparex, a producer of release liners and engineered films, has expanded its sustainable portfolio with bio-based polyethylene (PE) and polypropylene (PP) pouch films made from from ISCC compliant sources based on a mass balance approach.

From the beginning of April, Loparex customers will be able to order pouch films made of PE and PP from ISCC compliant sources offering lower carbon footprint versus conventional PE and PP while still supporting the same converting options, including silicone coating, printing, and custom-colored materials.

The use of circular feedstocks reduces carbon footprints on two fronts: by avoiding the use of fossil fuel-based virgin materials and by re-using waste that would otherwise be incinerated. As with bio-films, recycled PE and PP from mass balance can be used to produce silicone coated and uncoated, printed, and colored films.

These new film options further expand Loparex’s portfolio of FSC-certified, compostable, bio-based, and biodegradable liner options.

-Orsted plans to develop renewable hydrogen plant in NW Europe

Denmark’s Orsted on Wednesday unveiled plans to develop one of the world’s largest renewable hydrogen plants to be linked to industrial demand in the Netherlands and Belgium.

The “SeaH2Land” project aims to link gigawatt(GW)-scale electrolysis to the large industrial demand in the Dutch-Flemish North Sea Port cluster through an envisaged regional cross-border pipeline.

The green electricity required to produce the renewable hydrogen is proposed to come from the build-out of additional large-scale offshore wind.

The SeaH2Land vision includes a renewable hydrogen production facility of 1GW by 2030 to be developed by Orsted to enable sustainably-produced steel, ammonia, ethylene, and fuels in the future.

If realised, the electrolyser, which will produce the renewable hydrogen, will convert about 20% of the current hydrogen consumption in the region to renewable hydrogen.

Project partners include ArcelorMittal, Yara, Dow Benelux, and Zeeland Refinery, with talks now planned with regulatory authorities on the framework and policies needed to support the huge project.

This Summer, ESKA will relaunch ESKA Sparkling using 100% recycled plastic bottles. For ESKA, this marks the complete elimination of all first use plastic bottles across its entire product line – a commitment made with the transition of its natural spring water bottles to recycled plastic in 2020. In fact, ESKA will be the first leading Canadian brand to make carbonated water bottles with recycled plastic. ESKA Sparkling is carbonated natural spring water available in Original and natural Lemon, Lime and Orange fruit flavors.

The recycled plastic in ESKA’s spring and sparkling water bottles are sourced from Quebec’s Blue Box and other recycling systems. The rPET bottles are themselves recyclable, which is part of the brand’s commitment to environmental sustainability and contributing to the circular economy. In fact, these recycled PET bottles in turn become new bottles, that means continuous reuse – an idea that ESKA calls the “Recycle of Life”.

–POLYPROPYLENE (PP) PRICES DRIFT LOWER IN ASIA

This week, PP prices dropped in Asia. The price fall was prompted by persistent sluggish regional demand trends coupled with a drop in upstream propylene values.

Weaker PP futures on the Dalian Commodity Exchange in China and lower import offers from overseas suppliers further pressured prices lower.

In Far East Asia PP raffia and PP injection prices were assessed at the USD 1230-1290/mt CFR levels a fall of USD (-10/mt) from the previous week. PP film prices were assessed at the USD 1250-1320/mt CFR levels, while PP block copolymer prices were assessed at the USD 1270-1340/mt CFR levels, both down USD (-10/mt) from last week. BOPP prices were assessed at the USD 1250-1320/mt CFR levels, a week on week fall of USD (-10/mt).

In Southeast Asia, PP raffia and PP injection grade prices were assessed at the USD 1400-1450/mt CFR levels, a sharp drop of USD (-30/-40/mt) from the previous week. BOPP prices were assessed at the USD 1410-1470/mt CFR levels, while PP film prices were at the USD 1410-1470/mt CFR levels, both down USD (-30/-40/mt) from last week. PP block copolymer prices were at the USD 1450-1510/mt CFR levels, a week on week fall of USD (-30/-40/mt).

In Vietnam, Chinese producers have offered their PP raffia and PP injection grades (oil based) at the USD 1440-1460/mt CFR levels, for a shipment in April 2021

ChemAnalyst provides benchmark prices for up to 250 chemical and petrochemical products in more than 12 countries:

Petrochemicals

Polymer & Resin

Elastomer & Rubber

Bulk Chemicals & Fertilizer

Feedstock & Intermediates

Specialty Chemicals

-Recycling plastic materials – an objective to be pursued

As a processer of plastic materials, Agriplast works with a material that boasts the best recyclability level, but which is nevertheless used and managed as if not recyclable at all. For this reason, the company has decided to change the management of the end of life of plastic products.

Using plastic materials is necessary to produce and preserve food. Over the next few years, the growth in global population will mean it will be increasingly difficult to guarantee food to everyone.

Plastic is therefore a solution to meet the increasing demand for food, as it helps improve intensive cultivation techniques. However, plastic materials are often demonized due to the environmental devastation caused by their mismanagement, which has nothing to do with their use. The true issue for sustainability is in fact the recycling of plastic materials, which can largely be recovered, if subjected to suitable processes.

-Swiss accessories firm Riri uses recycled polyester for zip range

Riri has launched the use of recycled polyester as a production standard for its zip range. Riri is a leader in the production of zippers and buttons, with its two distinctive brand names; Riri, a point of reference for the production of zippers, pre-cut in metal and die-cast in plastic and zinc, and Cobrax, a leader in rivet and button manufacturing.

By employing recycled polyester as production standard for the zip range, the contribution to sustainability on a quantitative level will be significant. The company, in fact, will reduce emissions resulting from polyester purchase by 32 per cent; thus, carbon footprint will be cut down by 3 per cent, for zip production. As a result, 460,000 kg of CO2 per year is saved, the same as 169 return flights from Geneva to New York, Riri said in a media statement.

All the recycled polyester is GRS (Global Recycled Standard)-certified, highlighting Riri’s constant commitment to choosing suppliers that meet the industry’s international standards. The recycled polyester used in tapes for zips is made from recycled polyester fibres, both pre- (20 per cent) and post-consumer (80 per cent). An important contribution is made to the goal of increasing the global use of recycled polyester, as stated by Textile Exchange, from 14 per cent to 20 per cent by 2030, according to Riri.

Nonwoven PA6Recycling Hydrogen