Nylon6 – Chemical-recycling – rPS 30-12-2022 - Arhive

Nylon6 – Chemical-recycling – rPS

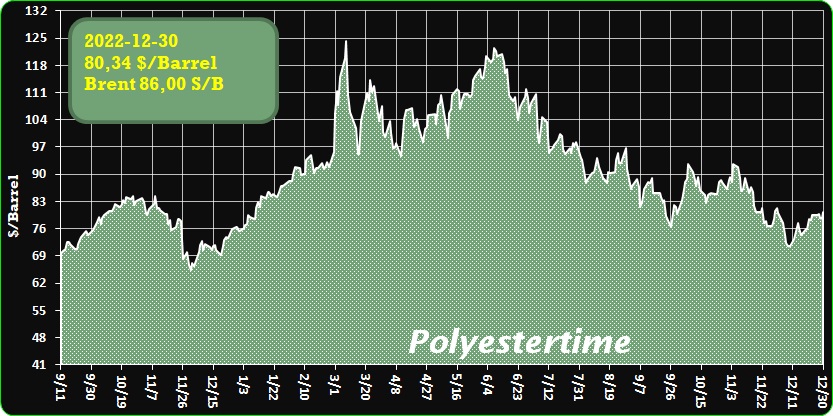

Crude Oil Prices Trend

-Chemical Recycling of Polyethylene Waste

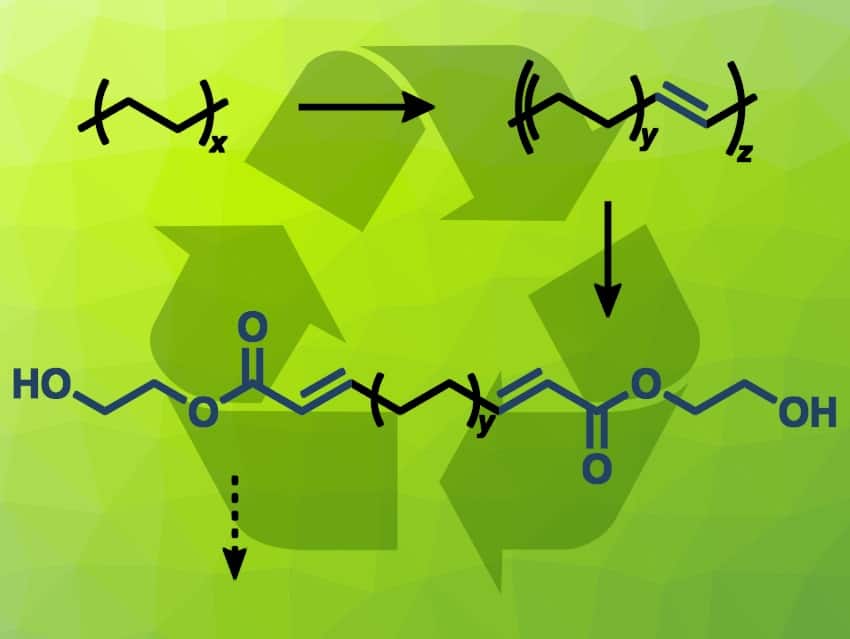

Polyolefins are widely used plastics. Often, post-consumer plastic waste is burnt or kept in landfills instead of being recycled. Methods for the conversion of polyolefins into useful monomers or other chemical feedstocks would, thus, be useful. However, the cleavage of C–C bonds in polyolefins such as polyethylene (PE) can require large amounts of energy and give a hard-to-control mixture of products. An alternative approach is the chemical recycling of polyethylene waste into a different monomer, which can be repolymerized to obtain plastics with similar properties to PE.

Anne M. LaPointe, Geoffrey W. Coates, Cornell University, Ithaca, NY, USA, Massimiliano Delferro, Argonne National Laboratory, Lemont, IL, USA, and University of Chicago, IL, USA, and colleagues have developed a route for the chemical recycling of high-density polyethylene (HDPE) waste that gives monomers that can be re- and depolymerized in a circular process. The team first dehydrogenated the HDPE using an iridium POCOP ethylene complex as the catalyst (POCOP-H = 1,3,5-[(tBu2)PO]3C6H3), which introduces double bonds (pictured at the top right). The partially unsaturated polymer was then subjected to a cross-metathesis reaction with 2-hydroxyethyl acrylate to break the chains down into smaller parts and introduce functional groups that can be used for repolymerization (product pictured).

The resulting monomers can be hydrogenated to remove the C=C double bonds and can then be used to make new polymers. Partial aminolysis can be used to create a monomer mixture that is suitable for cross-linking, improving the mechanical properties of the resulting materials. The developed monomers can be polymerized to give a material with comparable mechanical and thermal properties to HDPE. After use, depolymerization can be used to recover the monomers and allow chemical recycling.

-Showa Denko low-carbon ammonia produced from used plastics reduces CO2 emission by more than 80%

Showa Denko KK (SDK) has confirmed that its process to produce “low-carbon ammonia” from used plastics at its Kawasaki Plant (Kawasaki City, Kanagawa Prefecture) emits more than 80% less GHGs (including CO2) than other conventional processes to produce ammonia from fossil fuels, said the company.

SDK has confirmed this GHG reduction effect with a method of calculation whose conformity with ISO has been certified by Japan Life Cycle Assessment Facilitation Centre (LCAF), which is an independent observer. Nylon6 – Chemical-recycling – rPS

Thus, SDK has confirmed its low-carbon ammonia’s excellent environmental performance with a method certified by a third party as the only case in Japan.

We remind, Showa Denko has decided to license its technology to produce vinyl acetate monomer (VAM) to Asian Paints Limited, a leading paint and decor company in India. In addition, SDK will provide Asian Paints with catalysts to be used for the company’s VAM production.

-The Autorité de la concurrence joins the debate on plastic recycling

A referral to the Autorité de la concurrence can have a boomerang effect. The government has just experienced this in terms of managing the plastic waste sector. Questioned about a draft decree on the approval procedure for eco-organizations in the household packaging sector, the Autorité requests a framework for the de facto exclusivity granted, last spring, to the eco-organization -Citeo organisme on the management of plastic waste, which is not sufficiently recycled, if at all. Nylon6 – Chemical-recycling – rPS

By a decree of 15 March, about which the Autorité de la concurrence recalls that it has not been seized by the public authorities, Citeo has been granted ownership of packaging such as pots – mainly yoghurt – and polystyrene (PS) trays, plastic films and dark and opaque polyethylene terephthalate (PET) bottles and trays. This caused an uproar, both from environmental service companies and local communities. Professional organisations have even referred the matter to the Council of State…

Containment

The Autorité de la concurrence therefore participates in turn in the debate. In its opinion just rendered, the Commission considers that “exclusivity for the organization […] risks leading to the closure or compartmentalization of the plastics sector, insofar as it allows eco-organizations to exercise complete control over the supply and outlets of plastics not yet recycled. » Nylon6 – Chemical-recycling – rPS

The Autorité nevertheless acknowledges that such exclusivity appears “necessary” insofar as it gives eco-organizations – in this case Citeo – the ability to structure investments, and therefore the sector itself. It also considers it “proportionate” since it concerns only part of the global deposit of plastic waste. However, she concludes, this exclusivity must be limited and not go beyond 2029.

“This is a strong message from the Autorité de la concurrence,” comments Bertrand Bohain, general delegate of the association of local authorities Cercle national ducyclisme. “Finally, we are heard for the first time by a public authority, reacts for his part, the president of the plastics branch of the Professional Federation of Recycling Companies, Christophe Viant. For years, Citeo has been trying to get its hands on some of the plastic waste. »

Major breakthrough for the circular economy

Coincidentally, the opinion of the Autorité de la concurrence is delivered while Citeo is setting up new recycling channels. The eco-organization announced Wednesday the launch of a “large-scale” recycling channel for polystyrene, with the possibility of a return to food use. Clearly, a major step forward for the development of a circular economy in the agri-food industry. Nylon6 – Chemical-recycling – rPS

Following a call for tenders, Citeo has selected two proposals to eventually recycle at least 10,000 tonnes per year. Most of the market, i.e. 80% of the flow managed by Citeo, will supply for nine years a plant that the Belgian company Indaver is due to open in Antwerp in 2024. This production unit, with a European vocation, will feed, thanks to a process based on pyrolysis, a raw material which, once polymerized in Belgium, will become recycled plastic for food use.

-Nova Chemicals completes construction of Sarnia-area expansion

Nova Chemicals officials say the company has finished construction of its new polyethylene manufacturing site on Rokeby Line in St. Clair Township and the expansion of its Corunna facility next door.

Nova began work on the new plant and the expansion in 2017, and construction continued through the pandemic. Nylon6 – Chemical-recycling – rPS

Together, the two projects cost more than $2 billion and provided work for more than 7,000 construction workers, the company said Friday in a statement.

“We’re pleased to have completed the construction phase of the projects, and our team is now fully focused on safely completing post-construction activities prior to starting the commissioning phase of this flagship asset,” said Rob Thompson, Nova Chemicals’ vice-president of manufacturing east.

“This has been a tremendous effort across the organization,” he said. “During unprecedented conditions, everyone involved has worked diligently to bring our vision to reality and we look forward to celebrating the startup of the Rokeby Site with our stakeholders in 2023.”

The new plant on Rokeby Line has the capacity to produce approximately one-billion pounds of polyethylene plastic a year. It uses ethylene Nova produces at the Corunna site from natural gas liquids, and the recent project expanded that site’s capacity by more than 50 per cent. Nylon6 – Chemical-recycling – rPS

Nova Chemicals is the largest private employer in the Sarnia area with more than 1,000 employees in the region, according to its website.

Along with the Rokeby and Corunna manufacturing locations, it has a local corporate office and already produces polyethylene at its nearby Moore and St. Clair River sites.

The new plant and expansion are expected to add 150 full-time jobs.

“Post-construction commissioning activities at the Rokeby Site are fully underway with several on-site unit operations in the startup phase,” company officials said.

Initially, the company said the new plant and the expansion would begin operating in late 2021, but then the pandemic arrived and work at the site was slowed.

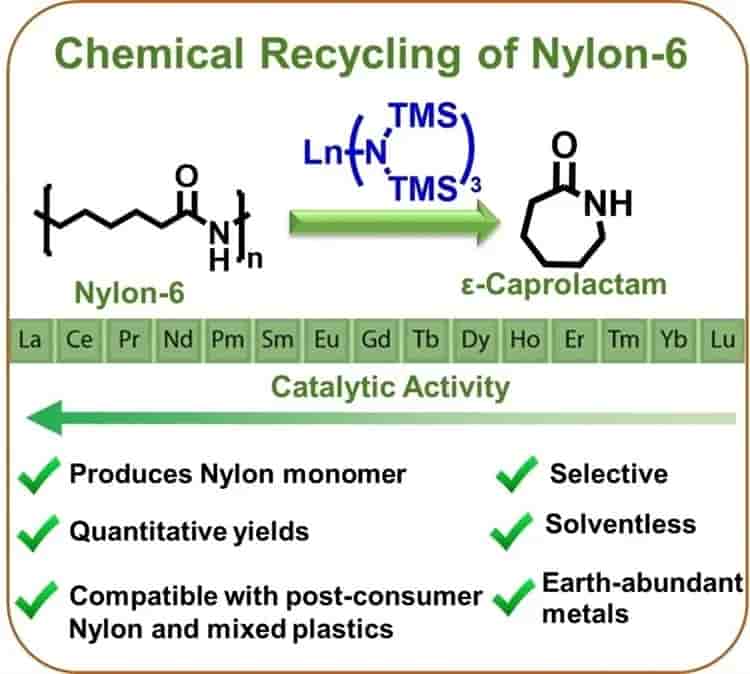

-New Technique to Recycle Nylon-6

Strong, non-biodegradable plastic, known as Nylon-6, cannot be recycled in the traditional sense. A team from the USA has recently revealed a new technique in the journal Angewandte Chemie.

Nylon-6 can be depolymerized selectively, nearly quantitatively, with no solvent, and at moderate temperatures to recover the monomer, ε-caprolactam, using a readily available lanthanum trisamido catalyst. Similar to unthreading pearls from a chain, the monomers are taken out of one end of the polymer one at a time.

Stockings are typically made of nylon fabric. Manufacturing automobiles, packaging, infrastructure, textiles, and fishing are just a few industries where it is the preferred material. Nylon6 – Chemical-recycling – rPS

Its beneficial qualities, including elasticity, chemical resistance, high tensile strength, and high abrasion resistance, prevent it from degrading naturally. For instance, about 10% of the plastic waste in the oceans is leftover nylon fishing nets.

On an industrial scale, 5 million tons of ε-caprolactam are polymerized using the ring-opening method each year to create the variant Nylon-6. By 2026, the market is anticipated to generate 21.5 billion dollars. The threat to the environment and human health is growing in tandem with the growth of trash mounds.

Nylon-6 manufacturing also produces a significant amount of CO2. A pricey, multi-step process is used to create the monomer, ε-caprolactam, from raw materials derived from fossil fuels. Reclamation would save energy, reduce production costs, and conserve resources. Therefore, there is a high demand for Nylon-6 in a circular economy.

Nylon-6 is extremely challenging to recycle, whereas it is slowly picking up some other plastics. It cannot be melted to take on a new shape because the high temperatures needed cause it to partially decompose. Nylon6 – Chemical-recycling – rPS

It also cannot be burned to produce energy because it produces harmful byproducts such as hydrogen cyanide. Previous techniques for recycling chemicals are either too complicated and ineffective or require questionable chemicals.

A new, effective catalytic process for recycling Nylon-6 has been created by a team led by Yosi Kratish and Tobin J. Marks from Northwestern University in Evanston, USA, and the National Renewable Energy Laboratory in Golden, USA.

With over 95% selectivity and over 90% yield, Nylon-6 is depolymerized to ε-caprolactam at the comparably low temperature of 240 °C without using solvents or hazardous chemicals. Polyethylene, Polypropylene, or Polyethylene Terephthalate mixtures do not, however, cause any interference. Nylon6 – Chemical-recycling – rPS

The catalyst developed by the team, based on commercially available trisamido complexes of rare earth metals, is crucial to their success. The most active catalyst was a lanthanum complex. Calculations and experimental data point to a novel mechanism for the reaction.

The catalyst is covalently attached to the polymer, and a hydrogen ion is removed from a terminal amide N-H bond in the first step. Then, in a backbiting procedure, the ε-caprolactam units are separated from the chain’s end one by one.

-MEG supply in Europe may be reduced at the beginning of next year

The supply of monoethylene glycol (MEG) in Europe may decline early next year as plant utilization remains low due to unfavorable sales conditions, ICIS said.

Imports can also be low due to the high cost of freight from the U.S. to Europe. European MEG market conditions have been exceptionally tight due to the sharp rise in production costs caused by the energy price crisis starting in the second quarter of 2022.

This year saw a big difference between spot and contract prices, which caused tensions between consumers and sellers. Larger consumers took contract material at a higher price, and this affected the demand for spot volumes. Nylon6 – Chemical-recycling – rPS

As a result, contract negotiations for 2023 were very difficult, and in some cases, consumers sought to change the distribution of volumes and the terms of the contract. Consumers expect to increase spot purchases in 2023 as average spot prices were lower than contract prices.

There is still uncertainty about how gas prices will change in 2023. There is also continued discontent over the often postponed agreements on European contracts. The December contract remains unconfirmed due to a lack of agreement in the market. Market participants are waiting for the approval of the January contract price for ethylene in order to understand the direction of pricing.

Local MEG shipments to Europe are expected to remain subdued in early 2023 due to continued pressure on production costs and low production margins. The situation is similar in the US, where meg demand is expected to remain low, leading to low production utilization.

In addition, market participants can potentially switch from the production of MEG to the production of ethylene oxide, since the production margin there is higher.

In Asia, there is hope that domestic demand will recover from the easing of restrictive policies on COVID-19. There are fears that the increase in supply from new projects in China in the future will exceed demand.

Earlier it was reported that imports of monoethylene glycol (MEG) to China decreased by 9.3% compared with October to 546.29 thousand tons in November due to the continuing reduction in supplies. The sources said major Asian and Middle Eastern producers continued to restrict production due to low profitability, and expectations of low demand at the end of the year also reduced consumer interest in imported goods. Compared to November 2021, MEG imports into the country decreased by 26.5%. As for exports, the figure in November rose to 3.44 thousand tons compared with 1.49 thousand tons in October, as shown by data. Nylon6 – Chemical-recycling – rPS

MEG, along with terephthalic acid (TPA), is one of the main raw materials for the production of polyethylene terephthalate (PET).

According to the ScanPlast review, the estimated consumption of PET in October of this year decreased by 16% compared to a year earlier and amounted to 58.53 thousand tons (against 69.28 thousand tons in October 2021). According to the results of ten months of 2022, 680.14 thousand tons of PET were processed in Russia, which is 1% less than the same indicator last year.

-Sumitomo Chemical completes construction of pilot facility for acrylic resin chemical recycling

Sumitomo Chemical has constructed a new pilot facility for chemical recycling of acrylic resin (polymethyl methacrylate or PMMA) at its Ehime Works in Niihama City, Ehime Prefecture, Japan, said the company.

Samples of chemically recycled methyl methacrylate or MMA monomer produced in this facility and acrylic resin made from the monomer will become available in spring 2023. The Company will accelerate the development of a circular system for acrylic resin that integrates all steps, from collection of used acrylic resin, to recycling of the collected resin into a monomer material, to use of the material as products.

Acrylic resins, which possess the highest level of transparency among plastics, as well as superior weatherability and processability, are used in a wide range of applications, such as automobile tail lamps, home appliances, water tanks, liquid crystal displays (LCDs), and protective partition panels to reduce the spread of droplets.

Meanwhile, as plastics are made from fossil resources, there is an urgent need to reduce greenhouse gas (GHG) emissions generated across the entire process, from production to disposal of plastics, as well as to promote the recycling of used plastics as resources.

Sumitomo Chemical has jointly developed with The Japan Steel Works, Ltd. (“JSW,” headquartered in Shinagawa-ku, Tokyo) a technology for pyrolyzing acrylic resin and recycling it, with high efficiency, into MMA monomer, which is a raw material for acrylic resin. The new pilot facility the Company has built at its Ehime Works is equipped with JSW’s twin-screw extruder. Nylon6 – Chemical-recycling – rPS

Sumitomo Chemical will validate the technology to recycle acrylic resin at a high quality and work on scaling the production process. The recycled MMA monomer will have the same level of quality, and its GHG emissions over the entire product life cycle are expected to be at least 60% less, compared to MMA monomer manufactured from fossil resources.

Sumitomo Chemical has also set out to build a circular system for acrylic resin, collecting acrylic plastic scraps and used acrylic resin from NIPPURA CO., LTD. (Miki-cho, Kita-gun, Kagawa Prefecture, Japan), a long-time business partner, as well as from major home appliance manufacturers, while also working to develop a customer base for acrylic resin made from the recycled MMA monomer. Nylon6 – Chemical-recycling – rPS

Going forward, Sumitomo Chemical will step up collaboration with partners in other industries on collection, recycling, and business development in order to accelerate the development of a circular system for acrylic resin.

In September 2022, Sumitomo Chemical launched the Meguri brand for plastic products made with recycling technology, as part of its effort to contribute to building a circular economy. The Meguri brand is put on products that meet certain criteria the Company has established, such as GHG emission reductions achieved.

Nylon6 – Chemical-recycling – rPS