Packaging Nonwoven Plastics Brics 28-10-2021 - Arhive

Packaging Nonwoven Plastics Brics

Crude Oil Prices Trend

-Italy’s Radici Group to showcase Sustainable Solutions at A + A2021

RadiciGroup is exhibiting the latest high resistance, lightweight and sustainable solutions at the A + A 2021 trade fair in Germany. This international show gave the Radici Group the opportunity to showcase the latest developments in industrial personal protective equipment (PPE) such as coveralls, gowns, caps, full hoods, shoe covers and boots.

Radici Group’s new product line is the result of a pandemic experience. We have turned our know-how into a new production line for sustainable personal protective equipment. These products are part of the new line Radipeople, a brand name that identifies the new protective workwear sold by the Radici Group. In a press release, Radici Group states that the final product is a traceable supply chain and special attention is paid to the selection of raw materials and the quality of the final product offered to the market.

“Radici Group’s efforts in the field of personal protective equipment began in March 2020, in the midst of a pandemic crisis in Bergamo, Italy, where we are based.” Maurizio Radici, Vice President of Radici Group, Said. “We have embarked on the use of diler spunbond as the main component for manufacturing protective gowns for medical professionals. Starting from scratch, in record speed, we are producing gowns. We have succeeded in establishing a chain of local manufacturers in. Today, with our established knowledge of material chemistry, backed by our extensive experience in the field of non-woven fabrics, we have turned our know-how and turned many industries. We are ready to switch to the production of protective garments suitable for environmental use. “

-Sidel to showcase line solution and packaging innovations at CBST 2021

Sidel is among the companies showcasing its latest product offerings at the 10th China International Beverage Industry Exhibition on Science & Technology 2021, happening on November 16 to 18. The trade show, in Shanghai, gathers key players in the beverage industry. Participants will be able to check out Sidel’s complete line solution and packaging products that highlight sustainability and digitalisation.

PET bottles are among the top items from Sidel and are the most suitable product for closed loop bottle-to-bottle recycling. It has a forecasted CAGR of 3% between 2019 and 2024 (water and carbonated drinks segment) and are the more sustainable packaging option for drink packaging.

One of the products to be displayed is the FDA-approved Sidel Aseptic Combi Predis™, which features a dry preform sterilisation technology. This is best for sensitive beverages like dairy, isotonics, tea and juices as it helps promote better food safety and flexibility. The Sidel EvoBLOW Aseptic will also be equipped with Predis™, set to be showcased during the event. Packaging Nonwoven Plastics Brics

Another innovation is Actis™, a bottle plasma coating technology that extends the shelf life of PET bottles up to 5 times the normal. Featuring lightweight properties, this is already applied in more than 5 million bottles across the beverage market.

Courtesy of Sidel

-Coke hits back at Johnson on plastics

Coca-Cola has rebutted an attack on its use of plastics by prime minister Boris Johnson.

Johnson’s comments came from the same session for school pupils in which he caused a furore by criticising plastics recycling as “a red herring”.

The prime minister at first drew back from singling out Coca-Cola but then named the company.

He said: “There are about 12 companies, big corporations, that produce the overwhelming bulk of the world’s plastics – famous drink companies you may know but I won’t name, but why not – Coca-Cola, for instance. It produces huge quantities of plastic and we have got to find other ways of packaging [as] it’s ending up in the eco-system.”

A Coca-Cola Company spokesperson said: “The world has a packaging problem. As the world’s biggest beverage company, we have a responsibility to help solve it.

“We believe circular recycling solutions are imperative in creating a path to keep plastic out of our natural environments for good.

-Nestlé Waters Egypt launches country’s first water bottle made of 100% recycled plastics

Nestlé Pure Life has launched Egypt’s first water bottles made of 100% recycled plastics (rPET) in its 1.5 liters format as it continues its move towards more sustainable packaging.

The new bottles are made of high quality and food-grade recovered and reprocessed plastics known as rPET which stands for “Recycled Polyethylene Terephthalate.” The innovation was first introduced and approved by the European Union as safe to use, ensuring quality and safety. Products produced by Nestlé Waters Egypt go through a rigorous 10-step quality process and bottles undergo more than one million quality tests per year. Packaging Nonwoven Plastics Brics

Nestlé’s global commitment includes, investing a total of $2 billion to develop sustainable packaging solutions for food grade recycled plastic; in addition to its commitment to increase the usage of rPET in packaging materials by 50% worldwide by 2025.

The announcement came during a press conference held today which welcomed Mr. Moataz ElHout, Chairman and CEO of Nestlé Egypt, Dr. Rassem Dabbas, Business Executive Officer of Nestlé Waters Egypt, Mr. Ahmed Kamel Abdel Moneim, CEO and advisor to the Federation of Egyptian Industries, Dr. Walid Darwish, Advisor to the Minister of Trade and Industry for environmental policies, Mr. Magdy Anis, General Manager at The St. Regis Cairo and Chairman of Marriott Egypt Business Council, alongside representatives from Nestlé Waters Egypt, Bekia and the National Food Safety Authority.

-Eunomia: Key considerations for Integration of recycled content in plastic products

Eunomia Research & Consulting have carried out new research which has identified key considerations to verify recycled content claims in plastic products to inform actions in support of Canada’s target of achieving at least 50% recycled content in plastic products, where applicable, by 2030. This target aims to extend the life of materials, reduce waste and greenhouse gas emissions, and support the transition to a circular economy.

Currently, Canada generates approximately 3 million tonnes of plastic waste, of which 9% is recycled and represents a loss of approximately $8 billion in value to the Canadian economy. The remainder is discarded in landfills or leaks into the environment as plastic pollution, where it has caused harm to organisms and their habitats.

To address this, companies around the globe in various sectors across the economy are increasingly using recycled content and adopting voluntary recycled content targets for plastic products and packaging. As governments and industry consider actions to increase the use of recycled plastic, a critical element will be how to measure and verify recycled content in products.Packaging Nonwoven Plastics Brics

To support this approach, the Standards Council of Canada (SCC) and Environment and Climate Change Canada commissioned us to carry out a comparative assessment of existing and in-development North American and international standards and certification protocols for verifying recycled content in plastic products, following which the company identified needs for effective future certification programs.

The Crypton Companies (Crypton LLC and Nanotex LLC), industry leaders in high-performance fabrics for contract and residential interiors, has partnered with Hologenix®, LLC, whose CELLIANT® infrared technology is an ingredient in world-class brands across many categories. The two have collaborated to create a new textile innovation, Crypton® CELLIANT®, the first woven upholstery fabric with CELLIANT.

CELLIANT, ethically sourced minerals embedded into fibers, reflects natural body heat back to us as infrared energy. It has been clinically tested and proven to increase cellular oxygenation for improved energy, stronger performance, faster recovery, better sleep and overall enhanced wellbeing. With the tagline “easy care meets self-care,” the new Crypton CELLIANT fabric additionally offers Crypton’s legendary performance characteristics. These include moisture- resistance, stain-resistance, spill-repellence, odor-resistance and cleanability. Both Crypton’s contract fabrics and its Crypton Home lines will offer collections of this innovative blend of Crypton performance along with CELLIANT’s energy-enhancing properties, creating a new benchmark for performance fabrics in interior upholstery applications.

-Berry Global sees exponential growth in recycled plastics volumes – CEO

The use of recycled plastics for food service and other offerings is poised for exceptional growth, with Berry Global helping to enable that demand, its CEO said on Tuesday.

Berry recently announced a collaboration with restaurant chain Wendy’s and LyondellBasell to supply recycled plastic clear cups with 20% recycled content to Wendy’s US and Canadian restaurants in early 2022. It will start with large cups, and by 2023 all drink cups will use recycled plastic. Packaging Nonwoven Plastics Brics

“[Volumes] will grow exponentially. Wendy’s has a goal to translate this across their entire cup set and we wholly expect to be partnered with them to do just that,” said Tom Salmon, CEO of Berry Global, in an interview with ICIS.

In the first two years, volumes of chemically recycled polypropylene (PP) going into the cups will amount to around 10m lb (4,536 tonnes), which means a greater amount of waste plastics are being diverted from landfills, he noted.

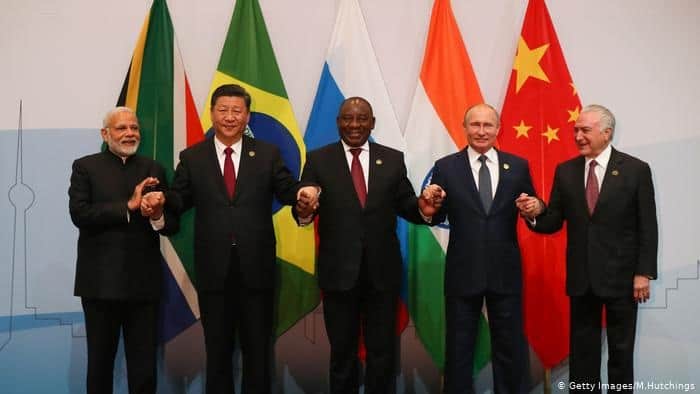

The first two decades of the 21st century have witnessed tectonic transformations. Modern technology has resulted in an exponential growth in mutual awareness and empowerment of increasingly interdependent global citizens.

The Westphalian state system of the last 372 years is having to increasingly reckon with the unfolding specter of non-state actors such as transnational organizations (both governmental and non-governmental), multinational corporations and terrorist networks.

Moving beyond their historical preoccupation with enhancing the destructive capabilities of their armed forces, states now need to ensure the productivity and prosperity that constitute critical components of national power. National security is inclusive of development. Power is being replaced by influence. The conventional understanding of power-so-called hard power-is being supplemented by soft power, smart power and sharp power; all undergirded by human resources, technologies and financial leverage.

This has changed the global hierarchy, producing new clusters of power in international relations. For example, while the economic rise of the then West Germany and Japan in the 1970s-in the midst of the Cold War-did not make them great powers, the economic rise of China since the 1990s-coinciding with the collapse of the Soviet Union-has given Beijing enormous system-shaping leverages. This explains how emerging economies have come to be as celebrated as a new category of influencers in international decision-making processes and structures. Packaging Nonwoven Plastics Brics

-Turkey’s Hayat Group announces 2nd phase investment in Vietnam factory

Turkey’s Hayat Group is set to launch the world’s fifth largest baby diaper brand named Molfix in the Vietnamese market. It recently announced the second phase of an investment in a Vietnamese factory to expand distribution of fast-moving consumer goods (FMCG), both across the nation and the region.

The Group had announced late last year its decision to invest $250 million to develop a factory in Vietnam’s Becamex-Binh Phuoc industrial and urban complex.

According to Cetin Murat, general director of Hayat Vietnam, the group has now completed the first phase of the project by setting up Hayat Vietnam Company with an investment of $100 million that can generate more than 500 jobs.

Murat was hopeful that the project will receive further support from southern Binh Phuoc province to expand the site in the second phase, according to Vietnamese media reports.

The Hayat factory in Vietnam is set to provide products to other potential markets throughout the Southeast Asian region. The total annual export value of Hayat Vietnam is estimated to be $50 million.

Packaging Nonwoven Plastics Brics