Packaging Petrochemicals Hydrogen 26-06-2021 - Arhive

Packaging Petrochemicals Hydrogen

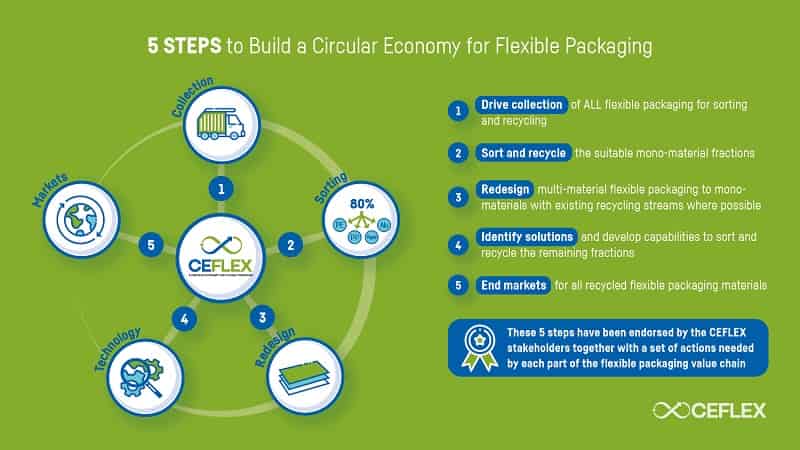

-Recycling Capabilities for Flexible Packaging in a Circular Economy

All recycling technologies are required to ensure material is retained in the economy to be used by end markets and applications says new position statement from CEFLEX.

The Circular Economy for Flexible Packaging (CEFLEX) initiative is a collaboration of over 170 European companies, associations and organisations representing the entire value chain of flexible packaging. Together, we work to make all flexible packaging in Europe circular by 2025.

To support CEFLEX’s vision and help the entire value chain move forward as one, a facilitated alignment process tackles key issues. Captured in a position statement, the latest addresses Recycling Capabilities for Flexible Packaging in a Circular Economy – and the need for:

- Fit for purpose recyclate in sufficient quantity, quality and value to be preferred over new virgin fossil-based materials by the market

- An essential need for high quality mechanical and physical recycling; but also, chemical recycling technologies to realise the required capacity and expanded end markets

- Coherent and complementary choices in packaging design using the CEFLEX Designing for a Circular Economy guidelines and improved sorting processes

- EPR schemes designed to support full material circularity together with the principle of covering the full net costs associated with this

-How to Get Plastic Packaging Back in a Circular Economy

Mechanical recycling can only take us so far, so we must look at advanced recycling methods to meet environmental objectives. However, the road is rocky.

We want packaging to protect, keep consumers safe, and make good use of material resources. We want to use barriers that reduce permeation of gases (carbon dioxide and oxygen) and moisture for products that are sensitive. We want to use colors and UV inhibitors the protect against the loss of vitamins and flavor. We might even want to brighten our package a bit. Packaging Petrochemicals Hydrogen

Then we want our packaging back. Recycling efforts cannot be considered successful until we get the containers, bottles, pouches, etc., returned — and that continues to be a challenge, particularly in the United States.

But what do we do with it once we get it back?

The existing mode of attack is mechanical recycling. The process separates materials based on type: glass, metal, paper, and plastics. Today, it is relatively easy to set up a mechanical recycling plant and reclaim many materials for next generation use.

However, with plastics, mechanical recycling can only take us so far. The feedstocks cannot deviate far from the original polymer. Those materials we add to enhance package performance — such as nylon, color, oxygen scavengers — can negatively impact processing and appearance of mechanically-recycled polymers.

-SABIC, BASF discuss plastics circular economy in Riyadh

- SABIC is working with UK-based company Plastic Energy to build its first commercial unit in Geleen

- Chemicals giant focuses on recycling plastics

RIYADH: SABIC and BASF, two of the world’s largest chemical producers, met in Riyadh to share insights into their respective programs to develop circular economy solutions for the plastics industry. Packaging Petrochemicals Hydrogen

SABIC shared progress it has made with TRUCIRCLE, a collection of processes that allow for the certification of polymers created through recycling of used and mixed plastic, certified bio-based renewable polymers, certified renewable polycarbonate (PC), and mechanically recycled polymers.

BASF discussed ChemCycling, a project to develop a pyrolysis technology that turns plastic waste into a secondary raw material called pyrolysis oil. The German multinational also explained how its plastic additives facilitate mechanical recycling of plastics.

SABIC is working with UK-based company Plastic Energy to build its first commercial unit in Geleen, The Netherlands, which will produce TRUCIRCLE certified circular polymers from recycled plastic.

Oerlikon Nonwoven will be showcasing its range of technology at next month’s ANEX-SINCE exhibition with a particular focus on solutions for the hygiene and medical, filtration and other industrial sectors.

Taking place in Shanghai between July 22 and 24, 2021, Oerlikon can be found at Stand 1H20.

Oerlikon Nonwoven offers a broad range of spunbond technology products and services. The process for manufacturing geotextiles from polyester or polypropylene in particular, has been optimized, and is now characterized by high production quality and the high production capacities and yields for manufacturing the latest, future-oriented nonwoven products. Packaging Petrochemicals Hydrogen

For the manufacture of hygiene and medical nonwovens, Oerlikon Nonwoven is offering its new QSR (Quality Sized Right) systems, which can be combined with a range of other features that enable differentiation within the market.

For the meltblown sector, Oerlikon supplies equipment for the manufacture of highly sophisticated filter media and numerous other high-end nonwoven applications.

-Consortium blows bottles from enzymatically-recycled plastics

A consortium of companies formed in April 2019 has produced food-grade PET bottles from enzymatically-recycled plastics.

Green chemistry company Carbios, and brand owners L’Oréal, Nestlé Waters, PepsiCo and Suntory Beverage & Food Europe, have manufactured sample bottles for products including Pepsi Max, Orangina and Perrier.

The announcement is the culmination of nearly 10 years’ research and development by Carbios to create a new process and supercharge an enzyme naturally occurring in compost heaps that normally breaks down leaf membranes of dead plants. By adapting this enzyme, Carbios has fine-tuned the technology and optimised this enzyme to break down any kind of PET (regardless of colour or complexity) into its building blocks, which can then be turned back into like-new, virgin-quality plastics.

According to a peer-reviewed article in Nature, PET can be broken down enzymatically by 97 per cent in 16 hours, which is said to be 10,000 times more efficient than any biological plastics recycling trial to date.

-Lucozade producer reveals world’s first endlessly recyclable plastic bottle

The promise of endlessly recycled PET plastic is one step closer today, as an industry consortium announced the successful production of the world’s first food-grade PET plastic bottles produced entirely from enzymatically recycled plastic.

Each consortium member – which includes Coleford-based Suntory Beverage and Food Europe, Carbios, L’Oréal, Nestlé Waters and PepsiCo – has successfully manufactured sample bottles – based on Carbios’ enzymatic PET recycling technology.

Orangina is one of the iconic brands modelling the technology which could see brands like Ribena and Lucozade follow suite. Packaging Petrochemicals Hydrogen

Suntory said this ground-breaking milestone is a key building block in its roadmap to full circularity for its drinks packaging, and its transition to removing fossil-fuel-based plastic from its packaging by 2030. The firm’s roadmap to 100 per cent sustainable plastic packing includes: investing in enzymatic recycling, creating bottles fit for circularity, using more recycled material and removing unnecessary plastic.

The news follows the Gloucestershire based company’s recent £7.8m investment to make its existing packaging more sustainable too. This includes new designs for its Ribena and Lucozade bottles that aid bottle-to-bottle recycling, the switch to 100 per cent recycled plastic for Lucozade Sport by the end of this year, and the switch to recyclable paper straws on its Ribena cartons.

-Born digital’ facilities set to transform PP recycling

Software and technology firm Emerson has signed a multi-year agreement with PureCycle Technologies to provide advanced digital technologies and automation for a network of global facilities enabling large-scale recycling of ‘a common – but rarely recycled – plastics’. Packaging Petrochemicals Hydrogen

Emerson’s Plantweb digital ecosystem was chosen for its breadth of digital solutions, including intelligent sensors and control valves, advanced operations software and systems, cloud data management and analytics.

“Unlike traditional manufacturing facilities coping with transforming legacy platforms to digital, PureCycle’s approach will enable all future facilities to be born digital,” said Dustin Olson, chief manufacturing officer of PureCycle Technologies. “With Emerson’s help, each PureCycle facility is expected to start up with the most advanced digital automation technologies available, allowing for faster project completion and fully integrated systems.

“PureCycle’s first-of-its-kind technology purifies waste plastics to remove colour, odour and other contaminants to create a near-virgin Ultra-Pure Recycled PP suitable for nearly any application. This provides a pathway to reverse low rates of global PP recycling and opens new opportunities for the plastics supply into all PP applications.”

-TOMRA to showcase latest sensor-based sorting updates at WasteExpo

At WasteExpo 2021, June 28-30 at the Las Vegas Convention Center, TOMRA Recycling will exhibit and highlight the latest sorting innovations from the company’s new generation AUTOSORT sensor-based sorting system. As a sponsoring partner of the Sustainability Talks event co-located with WasteExpo, TOMRA will also deliver a presentation on June 30, focusing on recycling’s role in offering ideas and solutions to advance the circular economy. Packaging Petrochemicals Hydrogen

On exhibit in TOMRA WasteExpo booth #2123, the ultracompact and highly versatile AUTOSORT excels across a vast range of material sorting applications, including municipal solid waste (MSW). AUTOSORT features multiple technologies, including SHARP EYE and FLYING BEAM, to deliver high-performance sorting accuracy across all target fractions, including the most complex to sort.

Team members, including TOMRA’s new Regional Director Americas, Ty Rhoad, will also have the latest details on the highly customizable AUTOSORT® SPEEDAIR. This additional component in the TOMRA AUTOSORT® range incorporates speed-controlled, fan-driven air inlets that generate a constant air stream over the conveyor belt to prevent light materials like paper and plastic film from moving, even at belt speeds reaching 19.7 ft/sec (6 m/sec).

-Domestic Prime Resin in Scarce Supply

There are still no signs indicating that resin prices have peaked. Indeed, producers are poised to raise prices in July on the heels of a June increase.

Most spot polyethylene (PE) and polypropylene (PP) prices held steady for a second consecutive week. Packaging Petrochemicals Hydrogen

Although buyers were wishing and hoping to talk the market down, there was still no real sign that US commodity resin prices were headed for a reversal, reports the PlasticsExchange in its Market Update.

Some market participants pointed to the return to healthy reactor rates and corresponding build in some upstream resin inventories, but domestically produced prime resin was still very difficult to source in the spot market, as force majeure conditions and sales allocations remain in place for many producers. There was some resistance to market pricing early in the week of June 14, but buyers that truly needed material were unable to find a better deal and came back later in the week to pay suppliers’ asking prices. Producers showed their intent on maintaining the firm undertone that has been the prevailing theme throughout this year by announcing another round of PE price increases for July. The July nominations came as June contracts have yet to be finalized but lean heavily toward implementation.

-PolyStyreneLoop opens EPS recycling plant: Correction

The PolyStyreneLoop co-operative has opened its polystyrene recycling plant in Terneuzen, the Netherlands, which is designed to facilitate closed-loop recycling of expandable polystyrene (EPS) waste. Packaging Petrochemicals Hydrogen

The facility was officially opened and fully operational on 16 June, with a capacity to recycle 3,300 t/yr of EPS demolition waste from buildings. The project will use a physical recycling process based on the Creasolv Technology as a dissolution technique, allowing the removal of additives and impurities such as cement and other chemical residues to deliver high-quality polystyrene recyclates.

PolyStyreneLoop is a co-operative taskforce represented by more than 70 companies operating in the polystyrene foam value chain. Members include producer Synthos, the EUMEPS (European Manufacturers of Expanded Polystyrene) and a number of foam manufacturers, additives suppliers, converters and recyclers.

Packaging Petrochemicals Hydrogen