Permeability and plastic packaging - Arhive

Permeability and plastic packaging

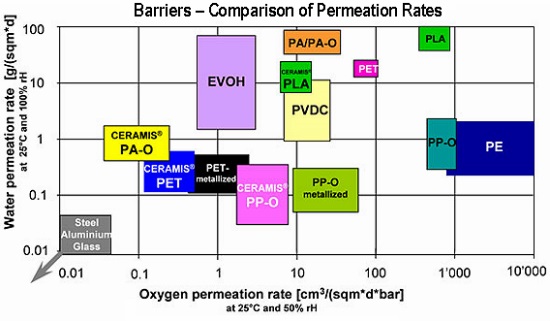

When we say that a material or packaging has a particular gas permeability, for instance oxygen, it gives us an idea of the amount of gas molecules that pass over the surface of the material or packaging. Although in daily life there is a common perception that plastics are “waterproof” this is not true, given that they allow the exchange of gases, vapours or radiations through them, according to the type of polymer used in the packaging production.

Plastic materials are formed, at molecular level, by a “ball” of long polymer chains, as known as “molecular ball”.These ball-like chains present voids, where molecules will pass to go through the packaging’s material. Obviously, these voids are not so big, so they will let more easily the littlest molecules pass, such as oxygen, water vapour, etc. Higher molecules, such as those forming scents, will diffuse with more difficulties through the polymer’s structure. Besides, this exchange depends on other factors, such as the type of polymer, temperature, humidity, etc.

In order to ensure the proper preservation of packaged food, it will be necessary to keep it as far as possible from the factors producing degradation. From permeability point of view, the possibility that the molecules of a particular gas enter into a packaging, usually from outside, may influences food preservation inside the packaging.

Therefore, the decision of choosing the best material or combination of materials, from permeability point of view, to ensure the correct shelf life of packaged food is a key factor when designing a packaging.

At the same time, a quality control would be necessary to verify periodically that these permeability values keep being in the expected values; to check that permeability values keep being acceptable when doing design modifications (for instance, thicknesses). This would be convenient to be applied in the companies of the sector (manufacturers, packagers and food companies).

Permeability measurement

In order to determine the transmission speed from a material to a particular gas, different methods can be used. The most used in packaging applications, where a high sensitivity and low permeabilities’ determination are required, are those using specific sensors. In other words, the sensor used allows only to detect molecules of the gas being measured, without interfering the other gases present in the environment.

In this kind of measures it is possible to determine permeability, both of film-like samples and complete packages (bottle-like, tub, etc.). The most critical fact is selecting the conditions to what the test has to be made. When we want to compare permeability values for different samples, a sample with its correspondent technical file or follow up permeability, it is needed that permeability values are determined in the same temperature and relative humidity conditions, otherwise it is not possible doing direct comparisons.