RPET Petrochemicals Carbon Fiber 29-11-2021 - Arhive

RPET Petrochemicals Carbon Fiber

PET Bottle Nylon RPET Petrochemicals 29-11-2021

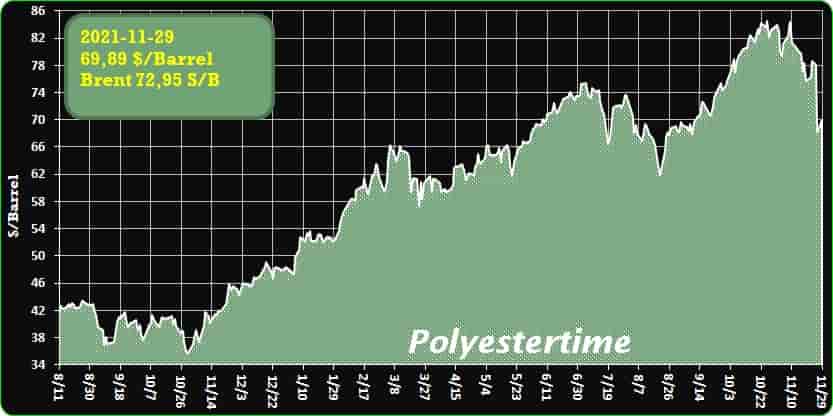

Crude Oil Prices Trend

-Zoltek Expands Carbon-Fiber Production in Mexico

New installation tracks growth in demand for industrial-grade carbon fiber in energy and transportation.

Zoltek Companies Inc., a global leader in industrial-grade carbon fiber, is expanding its carbon-fiber production capacity at its facility located in Guadalajara, Mexico. Production at the new 6,000-tonnes/year expansion will start up in early 2023 and will add to another 6,000-tonnes/year expansion recently completed in 2021.

Through its Mexican expansion, Zoltek will increase its North American carbon-fiber capacity to 20,000 tonnes/year. Zoltek’s global carbon-fiber production capacity will thereby increase to 35,000 tonnes/year, making it the largest carbon-fiber supplier in the world. RPET Bottle Petrochemicals Recycling

“Demand for our industrial-grade carbon fiber in energy and transportation applications continues to grow at a rapid pace,” notes David Purcell, Executive Vice President.

- Joint collaboration with Recycling Technologies, UK

- Europe’s first advanced chemical polystyrene recycling facility is expected to be operational in the second half of 2022

Frankfurt, November 25, 2021 – INEOS Styrolution, the global leader in styrenics, has today confirmed its decision to invest into a pilot plant for advanced recycling of polystyrene. The site will be set up in collaboration with Recycling Technologies in Swindon, UK. It is expected to be operational in the second half of 2022.

The decision announced today is a significant step forward launching polystyrene recycling through depolymerisation technology. Depolymerisation is an advanced recycling technology that converts polystyrene waste feedstock back into its main building block, Styrene which can then be used to manufacture new polystyrene with identical properties to the virgin material. The unique properties of polystyrene allow this efficient monomer recycling process to be harnessed avoiding the need to downcycle polystyrene. An additional benefit of depolymerisation is a significant decrease of greenhouse gas emissions when compared with the production of virgin polystyrene from naphtha.

The Swindon pilot plant will be based on Recycling Technologies’ fluidised bed reactor technology, which offers excellent scalability making it the technology of choice for future even larger recycling plants.

Dr. Alexander Glück, President EMEA at INEOS Styrolution comments, “I am excited to see this project move ahead. With Recycling Technologies, we have found a partner, who is not only offering a very attractive technology, but who is also sharing our own vision to avoid polystyrene ending up in landfills or being incinerated. We are on the right path to make polystyrene a circular material.” RPET Bottle Petrochemicals Recycling

Ravago Chemicals will exclusively distribute, SCHUTZEN Chemical Group’s BioBased patented Polymer Chemistries for the Textile, Paint & Coating market in Turkey.

Ravago Chemicals will exclusively represent & distribute in Turkey SCHUTZEN Chemical Group’s BioBased Bio-Focus products & patented Polymer Chemistries for the Textile Specialty chemical market, Paint & Coatings market in Turkey.The cooperation allows Ravago Chemicals to increase its innovation and sustainability focus in the Turkish market.

Some of the many important Bio-solutions already being offered which will be distributed in Turkey by Ravago Chemicals Turkey. On the one hand the Biobased Textile Specialty Chemicals: 100% Bio-Resin for Wrinkle Free Finishing; Bio-Denim Process Pigment & Reactive Wash Down Effect; and Energy Efficient 100% Bio-Soaping Agent for Post Reactive Washing. RPET Bottle Petrochemicals Recycling

On the other hand Biobased & Sustainable Additives for the Paint & Coating industry: Sustainable Biobased rheological Additives for water-based paints; and Sustainable Biobased Additive for Construction Chemicals.

Raj Tanna, Founder & Managing Director of Schützen Chemical Group said, “Bio-Based Economy is the future. The future is now and we are ready”. He further added, “The recent developments at COP26, will inevitably enforce Carbon tax on unsustainable markets & industries. SCHUTZEN Chemical Group & Ravago Chemicals Turkey together are taking a big leap forward to be more sustainable.”

Commenting on the association, Mrs. Duygu Icingir of RAVAGO Chemicals Turkey said, “Innovation and sustainability is in our DNA. We always look for green solutions to promote for better environment, reduce carbon footprint in all our production facilities and have regular internal trainings on this subject.

-Montello will invest 400 million in recycling

The projects also include a chemical recycling plant for plastic waste and the production of hydrogen, in addition to the energy recovery of residues.

Montello has announced an investment plan of 400 million euros for projects aimed at the circular economy, such as the enhancement of recycling activities, an innovative plant for the molecular disintegration of plastic waste, the production of hydrogen, energy self-sufficiency and district heating.

“Resources that can be spent entirely by 2025 if the Lombardy Region will support us with authorizations issued within the minimum time frame foreseen by the regulations”, said CEO Roberto Sancinelli during the 2nd Regional Forum for Sustainable Development.

Over 1 million tons of waste from the separate collection of post-consumer and organic wet plastic packaging (FORSU) are disposed of at the recycling plants of Montello, in the locality of the same name in Bergamo every year. 80% of what is delivered is regenerated in new products such as plastics, biomethane, carbon dioxide for carbonation in beverages and compost. This – Sancinelli emphasizes – is a yield that is well over 65% set for 2030 by the European Union.

The next step is the closing of the circle, through the energetic enhancement of the residues of the recycling activities, reused within the Bergamo site to replace the energy produced by fossil natural gas.

“In particular – Sancinelli clarifies – I refer to the production of steam for the washing processes of plastic, an essential operation for their recycling, and to the thermophilic process of anaerobic digestion which guarantees the sanitation of the fertilizer digestate. A district heating system will also be created with the residual heat to serve the industrial and public areas of the neighboring municipalities “.

Still in the field of renewable energy, a 4.5 MW photovoltaic system will be installed on the roofs of the warehouses. RPET Bottle Petrochemicals Recycling

-BASF’s engagement for the responsible use of plastics

With its broad portfolio and strong capabilities in research and development, BASF offers high-value products and solutions for various applications and constantly works on increasing the sustainability of its products. For example, our plastic materials are used in health, automotive, construction and consumer industries contributing to a reduction in CO2 emissions through light-weighting (i.e., less fuel consumption) and insulation (i.e., less heating) or extended life of packed goods (i.e., less food waste). Examples include high-performance fossil, bio-based, biomass-balanced and certified compostable products helping to address diverse societal needs and sustainability goals.

Plastics is an important material class providing many benefits for our society and should be part of the future if we want to reduce our climate footprint. For many applications, plastics help to increase efficiency by saving resources in production and use phases. Over the life of a product, plastics used in buildings, vehicles, packaging or electrical appliances save far more resources than were needed to produce them in the first place.

Plastics are easy to process which is one of the secrets of their success. Even complicated integrated components can be manufactured in only a few steps. At the same time, they offer an enormous variety of unique properties in the different applications. At the end of their lifetime, there can and should be recycled – mechanically, chemically or organically. When the entire product lifecycle is considered, plastics are usually the best option – both economically and environmentally.

BASF is working on innovative technologies that promote the recycling of plastics. This includes also research and development on new materials and compositions that facilitate recycling processes as well as processes to create value out of plastic waste. Within BASF’s ChemCyclingTM project, chemically recycled plastic waste is used as feedstock for production. By using plastic waste as a resource, BASF wants to make a significant contribution in reducing the amount of plastic waste. Chemical recycling provides an innovative way to reutilize plastic waste that is not currently recycled, such as mixed or uncleaned plastics. In this way, BASF wants to create value for the environment, society and the economy. RPET Bottle Petrochemicals Recycling

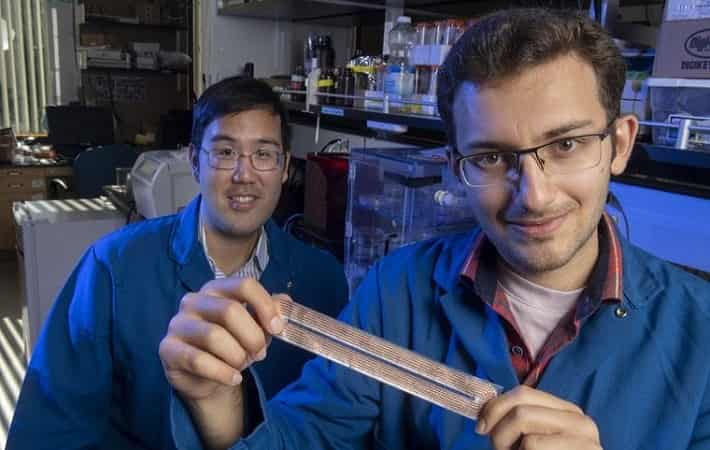

-U.S. researchers are developing battery-free smart fabrics

Engineers at the University of California, Irvine (UCI) have integrated advanced metamaterials into flexible textiles to create a system that allows battery-free communication between fabric and nearby devices. Researchers have used passive magnetic metamaterials based on etched foils of copper and aluminum to extend signal reach to more than four feet.

“If you put your smartphone or charge card close to the reader and pay for the purchase, we use near-field signaling technology.

Our fabric works on the same principle, but has significantly expanded its scope.” Said the co-author. Peter Tseng, Associate Professor of UCI Electrical Engineering and Computer Science.. “This means that you may be able to keep your cell phone in your pocket. You can simply hit your body against other textiles or readers to transfer power and information to and from your device. “

“With this invention, the wearer can digitally interact with nearby electronics and make secure payments with a single touch or swipe of the sleeve.” Lead Author Amirhossein Hajiaghajani, UCI PhD Student in Electrical Engineering and Computer Science..

Engineers at the University of California, Irvine (UCI) have integrated advanced metamaterials into flexible textiles to create a system that allows battery-free communication between fabric and nearby devices.

Researchers have used passive magnetic metamaterials based on etched foils of copper and aluminum to extend signal reach to more than four feet.

“Our fabric allows electronic devices to establish a signal as soon as you hold your garment over a wireless reader, allowing you to share information with a simple high five or handshake. Manually using a key or another wireless device.

It eliminates the need to unlock the car and is a badge for opening the gates of the facility, “said Hajiaghajani. RPET Bottle Petrochemicals Recycling

-US’ imports of polyester textured yarn to drop in coming months

The US’ imports of polyester textured yarn of HS code 540233 are expected to drop in the coming months as the country’s government has imposed an anti-dumping duty (ADD) on the same.RPET Bottle Petrochemicals Recycling

According to the US Department of Commerce, polyester textured yarn from Indonesia, Malaysia, Thailand and Vietnam is distributed in the US at lower than fair value. The Commerce Department has already calculated the ADD cash deposit rates which range between 2.58 per cent and 56 per cent. The US importers must post duty deposits at these ADD rates on the day the final determinations are published in the Federal Register.

The United States International Trade Commission (USITC) will announce the final determination on November 30, 2021.

The monthly average of overall US imports of polyester textured yarn was $12.27 million in the last quarter of 2020. It dropped by 13.73 per cent to $10.59 million between January 2021 and August 2021, according to Fibre2Fashion’s market analysis tool TexPro. It is estimated to rise by 6.66 per cent to a monthly average of $11.29 million between September 2021 and November 2021.

Between December 2021 and March 2022, the monthly average is expected to drop by 4.28 per cent to $10.81 million.

The collective monthly average of US imports of polyester textured yarn from Thailand, Vietnam, Malaysia and Indonesia was $3.85 million in the last quarter of 2020. It dropped by 5.70 per cent to a monthly average of $3.63 million between January 2021 and August 2021.

RPET Bottle Petrochemicals Recycling

Plastic Waste Recycling Sustainable Rubber BOPP Film Hydrogen PP 26-11-2021