PET circular plastic system 06-02-2023 - Arhive

PET circular plastic system

-PET, a circular plastic system? New study says not yet

Report says chemical recycling for PET could substantially boost circularity

While the strong recycling performance of clear PET beverage bottles in some European countries has given PET/polyester a reputation as a ‘circular plastic system’, a new synthesis study from system change company Systemiq begs to differ.

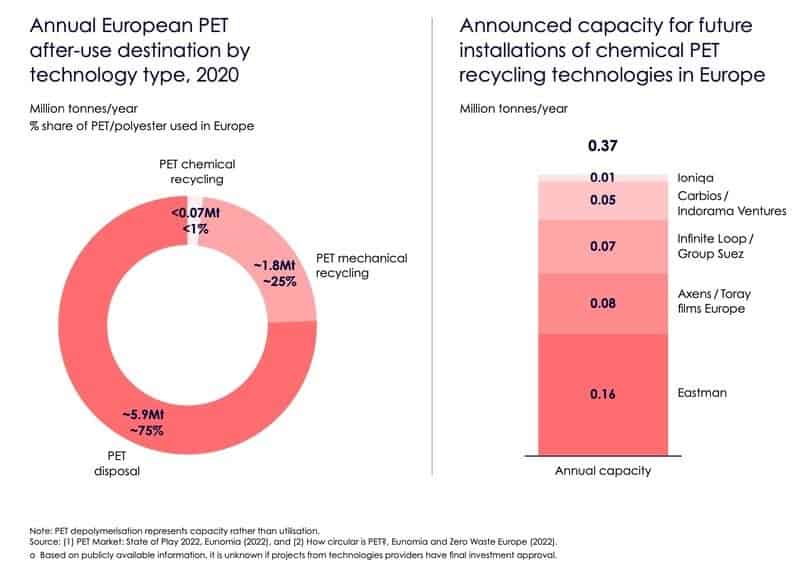

According to this report, with today’s limited recycling capabilities, only about one quarter of this material is being successfully recycled. Implementing chemical recycling technologies at scale alongside existing mechanical recycling approaches could set the stage for both positive environmental benefits and transformative success for the wider PET/polyester industry, the authors write. PET circular plastic system

Using a combination of plastic recycling approaches, not only could very high recycling rates be achieved but the carbon emissions from the PET packaging and textiles system would also be reduced. The study, entitled Circularity of PET/polyester packaging and textiles in Europe, is the first in a two-part series exploring circularity pathways for PET/polyester. Financed by Eastman and Interzero, an independent steering group comprised of experts from the public sector, academia, civil society, and industry provided strategic guidance. Drawing on insights from 80+ published reports, research, and advice from industry experts, it assesses the current state of PET/polyester packaging and textile circularity in Europe. PET circular plastic system

Among others, it looks at evidence for a positive role of PET/polyester recycling via depolymerisation alongside mechanical recycling and reuse.

As Sandeep Bangaru, VP of Circular Economy Platforms at Eastman Chemical Company, said: “We believe mechanical recycling should be used, when possible, but to keep more raw materials in the loop, chemical recycling is a necessary complement.”

“The world is facing a plastic waste crisis with far too little plastic waste being recycled…. The combination of mechanical and chemical recycling is a critical step closer toward a world without waste,” added Jacco De Haas, CCO at Interzero.

Among the findings of the study, there were three key highlights that emerged, namely:

- The PET/polyester system in Europe is mostly not circular today, with 75% of the material ending up in landfill or incineration.

- It is also largely dependent on virgin production using fossil-fuel based feedstocks. PET circular plastic system

- Chemical recycling technologies are emerging for PET/polyester at industrial scale. They offer the potential to increase circularity by complementing mechanical recycling and upcycling hard-to-recycle plastic waste into high quality recycled PET/polyester.

- The complementary application of mechanical, chemical recycling and reuse in the PET/polyester system has potential to optimise environmental and socioeconomic benefits.

The study also identified a major gap in the knowledge needed to design such a new system based on complementarity. A system model and scenario assessment tool are lacking. This model will therefore be the subject of the next phase of this project, and will help to determine whether this system vision is realistic, achievable, and beneficial in terms of economic and environmental outcomes.

It will also examine whether it would create an opportunity to reduce plastic waste, reduce dependence on fossil-fuel-based feedstocks, increase resource efficiency, and lower greenhouse gas emissions. PET circular plastic system

Outputs and insights from the model will be delivered in a second White Paper to be released in 2023, in which the future potential for complementarity of mechanical and chemical recycling of PET/polyester in Europe under different scenarios will be explored and material flows and environmental impacts of each scenario quantified.

Mechanical recycling of PET plastic bottles is a great success story in some parts of Europe, Ben Dixon, partner and head of Materials and Circular Economy at Systemiq, pointed out. But: “Research suggests that PET/polyester may be particularly well-suited to complementary solutions, with chemical recycling playing a significant role alongside mechanical recycling and reuse.” PET circular plastic system

Professor Kim Ragaert, full professor – Chair of Circular Plastics at Maastricht University, agreed, noting that ‘bottle PET has long been king of mechanical recycling, due to its unique combination of advantages’. “However, PET trays and polyester fibre are more complicated and of different qualities, and the conventional bottle segment is increasingly used in non-food applications like cosmetics. We must therefore seriously consider how to complement the mechanical recycling of PET with other technologies to avoid large volumes of precious polymer cascading out of the system via a “last stop” recycling into non-recovered textiles or incineration. This report gives us a much-needed overview of the tools available to us.”