PET-Like-Bioplastic – Petrochemicals 08-08-2022 - Arhive

PET-Like-Bioplastic – Petrochemicals

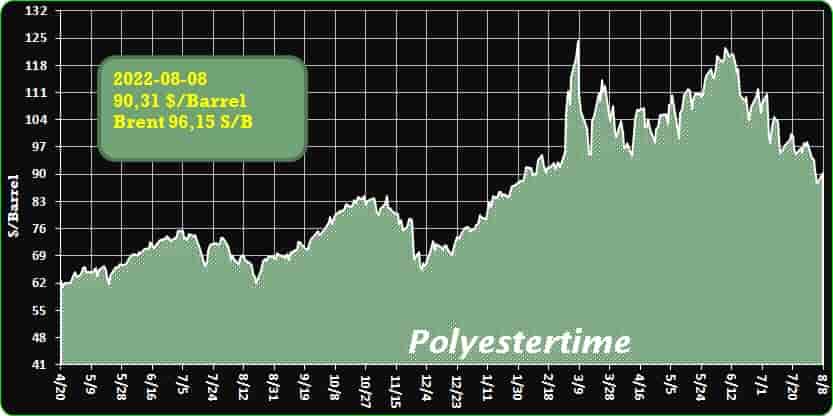

Crude Oil Prices Trend

-German Industrial Production Eked Out Surprise Gain in June

German industrial production eked out a surprise gain in June, as Europe’s manufacturing heart steadied after the initial shock of Russia’s war in Ukraine.

Output rose 0.4% in seasonally- and calendar-adjusted terms from May, with all three major categories of manufacturers posting gains. Even energy-intensive industry posted a 0.4% gain, after falling 5.4% since Russia’s invasion in February.

Energy output itself was flat on the month, while construction fell 0.8%, accelerating a decline that has accompanied a sharp drop in German business confidence in the second quarter. PET-Like-Bioplastic – Petrochemicals

The figures improve the odds that the German economy escaped contraction in the second quarter, having reported a preliminary estimate of zero GDP growth last week. However, they don’t fundamentally change the outlook for the next few months, which are set to be dominated by an acute shortage of natural gas and sky-high electricity prices. The German government intends to impose a surcharge on commercial gas bills from October, having so far stopped importers from passing on the increased price of supplies sourced from outside Russia.

Gas imports from Russia are currently running at only 20% of their normal levels as the Russian gas monopoly refuses to ship more through the Nord Stream 1 pipeline in a thinly-veiled political response to western sanctions on the country. Gazprom (MCX:GAZP) this week refused to take delivery of a key Siemens turbine after maintenance, which is needed at one of Nord Stream’s compressor stations. Gazprom said it wanted assurances that the turbine wouldn’t be affected by sanctions in future.

Appeals by German Chancellor Olaf Scholz, who held a press conference in front of the turbine to show off its readiness this week, have fallen on deaf ears.

-Moretto technology for PET treatment on show at Drinktec

In September the appointment is at Drinktec – the leading trade fair for the beverage industry where technologies and equipment for the entire production process will be exhibited, from raw materials to production, filling and packaging up to distribution.

Moretto will be present in the PETpoint area, an exclusive pavillon dedicated to PET bottles with the best solutions dedicated to the process of this material. Hall C5 – Stand 234.

Thanks to its properties – strenght, lightness, aromas barrier, easy processability – PET has seen a constant and gradual increase in its use especially in the beverage sector: 70% of PET is used for sparkling drinks, fruit juices, drinks and bottled waters packaging.

To the remarkable mechanical features have to be added the environmental advantages; PET generates a lower quantity of CO2 than glass or aluminum packaging.

It is one of the most recycled polymers that does not lose its mechanical and physical properties during the recovery process, a fundamental aspect to obtaining high quality plastic resins to be reintroduced several times in the production process.

According to this, it becomes essential to use equipment that ensures a perfect material treatment. PET-Like-Bioplastic – Petrochemicals

A crucial process in recycling is certainly the crystallization. MPK Moretto Krystallizer, exhibited at Drinktec, is a system designed to crystallize post-consumer materials – regrind and washed ready to be transformed. Perfectly treated they can be used with virgin plastic polymers for new production processes. MPK stands out for some important features in machinery that process post-consumer material such as the drop down cone with assisted device that allows the operator to quickly proceed with cleaning and maintenance activities thanks to the easy opening which takes only two minutes. An exceptional usability factor in a machine that process critical materials such as regrind and/or flakes. The internal mixer shaft with removable blades can be easily adapted to the different treated material. The blades have a wing profile that moves the material in a homogeneous way avoiding the formation of lumps during the crystallization phase. The hopper – with the patented stainless steel shockproof coating SPYRO – insulate the mixer body and contains the heat dispersion, increasing its energy efficiency. The control of the system processes is managed by a touch view control with a simple and intuitive interface.

MPK is a latest generation product designed for the intelligent factory, in fact it can be connected to other automations via web and remotely controlled through the supervision and management software MOWIS which achieves total connectivity via MODBUS, ETHERNET, OPC UA. PET-Like-Bioplastic – Petrochemicals

MPK is equipped with the Vortex filtration device which intercepts the dust of the process circuit increasing its autonomy. The Purex condensate separator filters the material flow back intercepting the volatile oily and/or resinous substances contained in the vapors, impurities typically present in post-consumer materials. Purex contains emissions into the atmosphere by condensing the vapors to 99%, thus separating the vapors. Purex protects the environment and people.

-Brüggemann Acquires Italy’s Auserpolimeri

Company continues to expand its polymer additives business with latest acquisition of functionalized polymers producer.

Brüggemann (U.S. office in Newton Square, Penn.) has further expanded its polymer additives business with the acquisition of Italy’s Auserpolimeri, a leading developer and manufacturer of chemically functionalised polyolefin-based polymers. These materials play a key role as impact modifiers, compatibilizers, coupling agents and adhesion promoters in improving the performance levels of engineering plastics for a wide range of applications. They ideally complement and complete Brüggemann’s existing range of high-performance additives, according to head of polymer additives Klaus Bergmann.

Auserpolimeri Srl specializes in the grafting of polymers by reactive extrusion. Polymers functionalised with this technology form the company’s product portfolio.

The company of the Eigenmann & Veronelli Group is known in the market for engineering polymers in particular for its high-quality technical advice and continuous product development. PET-Like-Bioplastic – Petrochemicals

According to a Brüggemann spokesperson, the application areas of grafted polymers are very diverse. “In the North American market, we also see a growing demand for engineering plastics with increasingly special properties. We look forward to now being able to offer even more solution possibilities worldwide.”

-Winner crowned for RECO Sustainable Young Designer Competition hosted by Indorama Ventures

Indorama Ventures Public Company Limited (IVL), a global sustainable chemical producer, named the winners of ‘RECO Young Designer Competition’, Thailand’s largest upcycling fashion design event, parading haute couture garments containing at least 60% recycled materials. PET-Like-Bioplastic – Petrochemicals

Eleven finalists showcased 33 handmade sustainable outfits at the 9th edition of the fashion show at IVL’s headquarters in Bangkok, using recycled PET and polyester items to craft creative fashions. Under the concept of ‘REVIVE: Start from the Street,’ RECO supports young Thai designers while raising awareness of recycling. The designs use a range of recycled materials including recycled PET yarns, discarded fabric from factories, and even repurposed safety belts.

RECO awarded finalists and winners with 500,000 baht in prizes to support their careers. First prize of 125,000 baht was awarded to 23-year-old emerging furniture designer Mr Prem Buachum for his ‘The Origin of Rebirth’ collection, using fabric recycled from post-consumer PET bottles. The first runner-up, Mr Sathitkhun Boonmee, was awarded 75,000 baht for his ‘Remembering Your Favorite Teddy Bear’ collection, using old dolls made of polyester fibers. Second runners-up, Mr Worameth Monthanom and Mr Tanakorn Sritong, received 50,000 baht for their ‘Regeneration of Nature (into Spring)’ collection, using unused fabrics and discarded PET film. Mr Napat Tansuwan, a finalist with his’ Don’t Judge’ collection, will go on to create designer merchandise for sponsor Buriram United Football Club using local weaving techniques from communities in Buriram province.

Mrs Aradhana Lohia Sharma, Vice President at Indorama Ventures and RECO Young Designer Competition Chairperson, said, “Since 2011, RECO’s ambition has been to uplift recycling and inspire people to realize the value of recyclable materials to produce great new products for daily life. PET-Like-Bioplastic – Petrochemicals

We have witnessed many thoughtful initiatives on upcycling through the collections created by our talented young Thai designers. The designs this year showcase stunning wearability and innovation while using a large percentage of recycle materials. Public interest in recycling has been growing immensely, and we are grateful to strengthen the relationship with partners like Buriram United Football Club.”

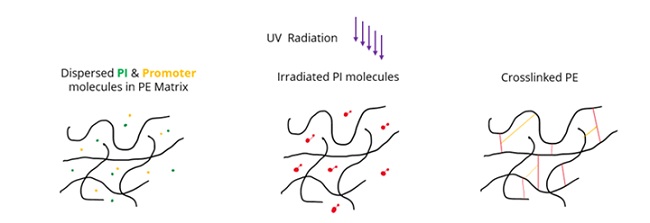

-Crosslinking Process Promises Thinner, Higher-Performance PE Films

Technology combines UV curing system with photo initiator promoter masterbatch.

Kafrit, a well-known Israeli masterbatch and additives manufacturer, has collaborated with start-up Israeli additives company N3Cure to create what they call a breakthrough in crosslinking technology for PE films. The system combines a proprietary masterbatch called Crossitol with UV curing radiation to enable processors to produce PE films that will crosslink to improve sustainability and cut costs.

Under the arrangement between the two companies, N3Cure, specialists in polymers, UV curing and sustainability, provides the raw material for the crosslinking additive to Kafrit, which compounds it into a masterbatch. The UV technology is furnished by an undisclosed curing system provider. PET-Like-Bioplastic – Petrochemicals

Crosslinking is the process of forming covalent bonds to join two polymer chains. With the Crossitol masterbatch, the process is triggered by UV radiation, applied by a UV curing system and integrated on an existing blown film line, resulting in a polymer web-like structure that is stronger than a regular, non-crosslinked polymer chain structure.

“UV crosslinking was designed to be a more cost-effective alternative to electronic-beam technology as it has a higher speed process, and lower maintenance and equipment costs. Unlike electronic-beam technology, selective crosslinking can be applied, and the finished product is easier to recycle,” said Kafrit’s Nadav Goldstein, v.p. of new business development.

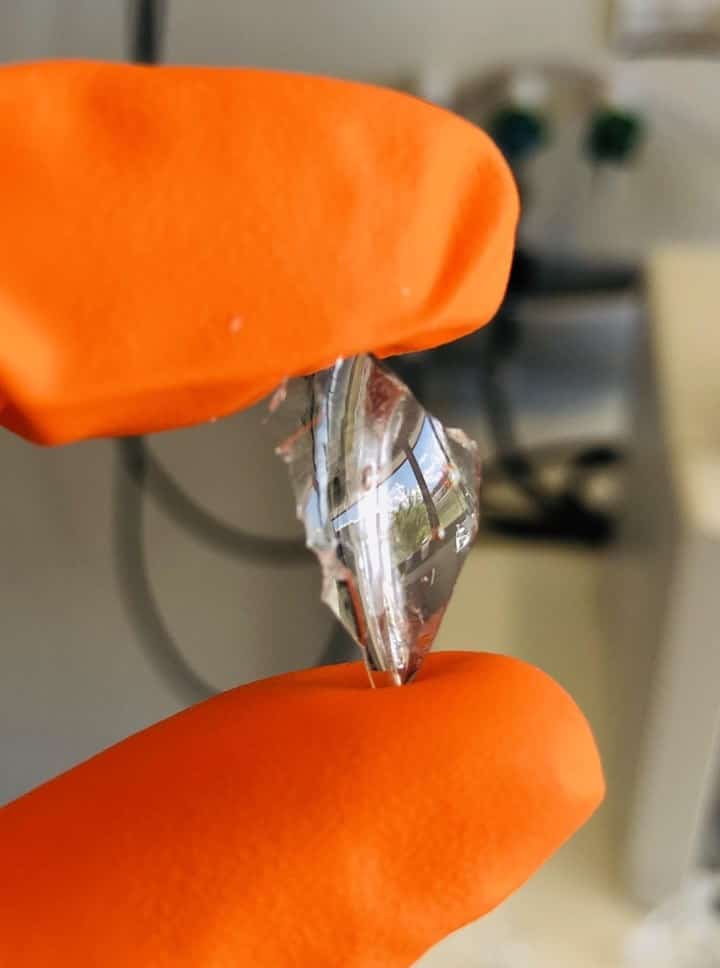

-PET-Like Bioplastic from Biomass

Switzerland’s EPFL School of Basic Sciences have developed a biomass derived plastic that is similar to PET.

We have been reporting on bioplastics derived from a variety of natural sources as contenders particularly for the five major commodity thermoplastics—PE, PP, PS, PVC, and PET. One of the latest is a new biomass-derived plastic similar to PET, that meets the criteria for replacing several current plastics while also being more environmentally friendly has been developed by scientists from public Swiss research university The École Polytechnique Fédérale de Lausanne, which specializes in natural sciences and engineering. PET-Like-Bioplastic – Petrochemicals

According to the researchers, led by professor Jeremy Luterbacher at EPFL’s School of Basic Sciences, producing competitive biomass-based plastics is not straightforward. He notes that there is a reason that conventional plastics are so widespread, as they combine low-cost, heat stability, mechanical strength, processability, and compatibility – features that any alternative plastic replacements must match or surpass. And so far, the task has been challenging.

Says Luterbacher, “We essentially just ‘cook’ wood or other non-edible plant material, such as agricultural wastes, in inexpensive chemicals to produce the plastic precursor in one step. By keeping the sugar structure intact within the molecular structure of the plastic, the chemistry is much simpler than current alternatives.”

-SK Geo Centric discusses its plans for a circular economy in Asia

“Recycling Today” recently spoke with SK Geo Centric’s CEO Na Kyung-Soo to discuss the company’s “Waste & Carbon Zero” strategy, its related investments and the plastic industry.

SK Geo Centric, a subsidiary of SK Innovation, has been developing petrochemicals in South Korea for 60 years. The company says its goal is to transform into the world’s leading plastic recycler by leveraging what it calls “vast opportunities” for the development of “urban oil fields.” PET-Like-Bioplastic – Petrochemicals

To achieve this, the company has launched its Waste & Carbon Zero strategy. Through 2021 and into 2022, SK Geo Centric has invested $260 million to further mechanical and advanced recycling of plastics and the necessary infrastructure. In the North American markets, SK Geo Centric has invested $56.5 million in Quebec-based Loop Industries, $55 million in PureCycle Technologies of Orlando, Florida, and $10 million with Closed Loop Partners, New York City, to advance circular business models, scalable recycling technologies and material recovery infrastructure in the U.S.

Recycling Today recently spoke with SK Geo Centric CEO Na Kyung-Soo to discuss the company’s Waste & Carbon Zero strategy, its investments and the plastic industry. The following interview has been edited for clarity.

PET-Like-Bioplastic – Petrochemicals