PET recycling – Silicon batteries 19-04-2023 - Arhive

PET recycling – Silicon batteries

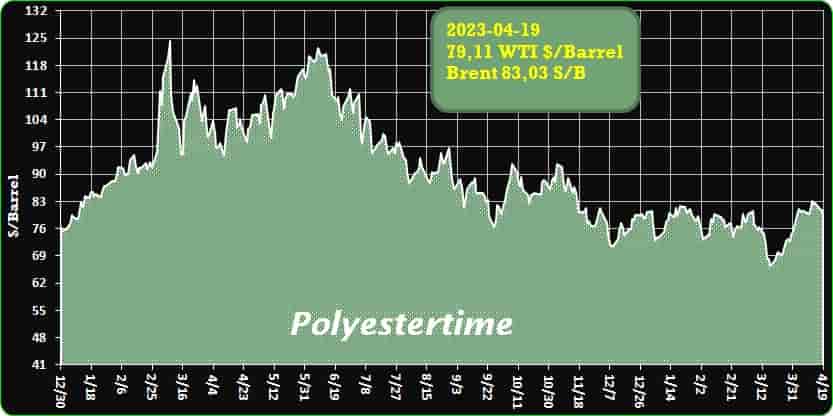

Crude Oil Prices Trend

Crude Oil Prices Trend by Polyestertime

-Origin, SCGP mull building biomass-to-chem plant

Origin Materials and SCGP Packaging are considering building a plant in southeastern Asia that would use Origin’s process technology to convert woody biomass into feedstock that can make polyester and carbon black, the companies said.

Origin and SCGP have a strategic partnership that includes a joint development agreement. Under it, the two will explore licensing Origin’s technology for a plant that could be built in one of the 10 countries that belong to the Association of Southeast Asian Nations (ASEAN). PET recycling – Silicon batteries

SCGP would supply eucalyptus feedstock. Origin has successfully processed and tested SCGP’s eucalyptus feedstock at its pilot plant in West Sacramento, California. It produced yields of chemicals similar to other biomass feedstock that Origin has evaluated.

Origin’s technology uses woody biomass as a chemical feedstock to produce 5-chloromethyl-furfural (CMF), an intermediate that can be used to make paraxylene (PX), furandicarboxylic acid (FDCA) and a host of other chemicals.

PX is used to make polyethylene terephthalate (PET). FDCA is used to make polyethylene furanoate (PEF), another polyester that has superior gas-barrier properties to PET.

In addition to CMF, Origin’s process also makes hydrothermal carbon (HTC), which can be converted into carbon black.

Origin and SCGP Packaging are evaluating the production of PET, PEF and carbon black from the output of the possible plant. PET recycling – Silicon batteries

-PET recycling with high purity at Reiling

For PET recycling with high purity, Reiling relies on sound quality inspection with sorting and material analysis systems from Sesotec.

The Reiling Group of Companies contributes to resource conservation as well as environmental and climate protection with efficient recycling processes. In addition to recycling glass, photovoltaic panels and wood, Reiling operates PET recycling plants at its sites in Hamm, Marienfeld and, since 2020, Burgbernheim.

In the PET recycling cycle in particular, the purity of the recycled end product is a prerequisite for rPET to be reused in a variety of ways. The production of new PET bottles or the manufacture of polyester fibers are just two individual examples of the use of rPET. If the highest quality recyclate is used, the recycling loop is closed. The need to produce virgin material recedes into the background. PET recycling – Silicon batteries

To produce recyclate of high grade and quality, Reiling Kunststoffrecycling relies on a multi-stage recycling process with state-of-the-art equipment. This is because only pure recyclate can be reused for a wide range of new products.

The PET bottles are delivered in the form of briquettes or pressed into bales. First, they are separated, then contaminants are removed, and the bottles are sorted by color. After crushing and washing processes, the PET flakes pass through Sesotec‘s Flake Purifier+ sorting systems, which perform separation of colors and metals as well as sorting by plastic type in a single pass.

In addition to state-of-the-art equipment, Reiling‘s internal quality management system throughout the entire treatment process ensures that only PET flakes of the highest purity leave the plant.

Complex manual, thermal and visual random sample analyses are necessary to evaluate the recyclate in the recycling process. PET recycling – Silicon batteries

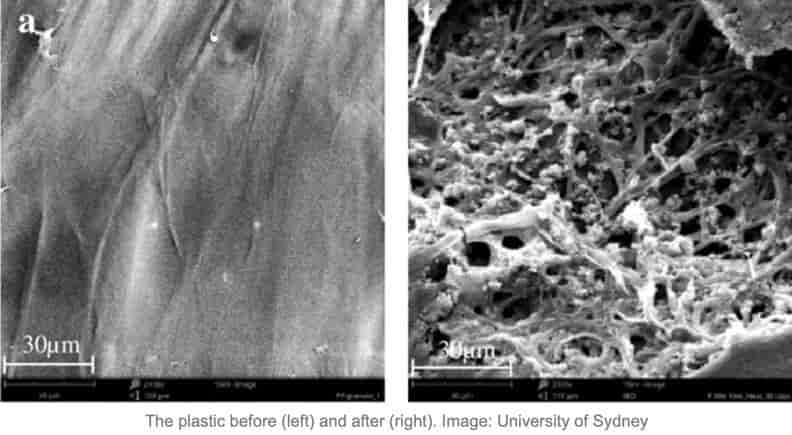

-Australian researchers find PP-eating fungi

Biodegradation demonstrated under lab conditions

As a popular choice for producing a wide range of everyday products, PP is one of the most commonly used plastics. But at the same time, it is one of the least recycled. It has been estimated that PP accounts for roughly 28 percent of the world’s plastic waste, while only 1 percent of it is recycled.

The reason, say researchers at the University of Sydney, is because of its short life as a packaging material and because it often becomes contaminated by other materials and plastics. Addressing this requires the development of new recycling methods – that have minimal environmental impact. A study conducted by the researchers published today in npj: Materials Degradation identifies two common strains of fungi found in soil and plants, Aspergillus terreus and Engyodontium album, that could contribute to solving the problem of the overrepresentation of PP in plastic waste and pollution globally and lead to a greater understanding of how plastic pollution might biodegrade naturally under certain conditions.

“Plastic pollution is by far one of the biggest waste issues of our time.

The vast majority of it isn’t adequately recycled, which means it often ends up in our oceans, rivers and in landfill. PET recycling – Silicon batteries

It’s been estimated that 109 million tonnes of plastic pollution have accumulated in the world’s rivers and 30 million tonnes now sit in the world’s oceans – with sources estimating this will soon surpass the total mass of fish,” said the study’s lead author from the University of Sydney’s School of Chemical and Biomolecular Engineering, PhD student Amira Farzana Samat.

The research team first pre-treated PP in various forms with one of three separate methods: ultraviolet light, heat, and Fenton’s reagent – an acidic solution of hydrogen peroxide and ferrous iron often used to oxidise contaminants. In a petri dish, the fungi were applied separately as single cultures to treated polypropylene.

-Gevo, LG Chem collaborate on bio-propylene development

Gevo, Inc. and chemical giant LG Chem, Ltd., have entered into a joint development agreement to develop bio-propylene, a building block for renewable chemicals, using Gevo’s Ethanol-to-Olefins (ETO) technology said Sustainableplastics.

The ETO process developed and patented by Gevo uses ethanol as a feedstock for the production of carbon neutral or carbon negative drop-in replacements for olefins such as propylene, isobutylene and hydrogen for use as standalone molecules or as feedstock to produce other biochemicals or biofuels, including sustainable aviation fuel. Gevo uses low-carbon renewable resource-based carbohydrates – varying from corn, sugar beets, rice straw, even wood – as raw materials. The technology also enables certain plastics, such as polyester, to be made with more sustainable ingredients.

Under the terms of the present agreement, Gevo will provide the core enabling technology and together the parties will collaborate to accelerate the pilot research, technical scale-up, and commercialisation of bio-propylene. PET recycling – Silicon batteries

“We believe Gevo’s ethanol to olefin’s process can be more capital and energy efficient than existing technologies to make the renewable olefin intermediates used in the production of chemicals or fuels,” said Gevo’s Chief Carbon and Innovation Officer, Dr. Paul Bloom.

Bio-propylene is a drop-in replacement for its conventionally produced fossil-based counterpart. It is projected to become a major player in the rapid growth of the bioplastic market and circular economy. Once commercialisation is achieved, bio-propylene could be used as a drop-in replacement for use in automobile interiors and exteriors, flooring, and diapers to replace petroleum products with bio-based materials with a low or negative carbon footprint.

“Our joint development agreement with Gevo helps LG Chem expand sustainable and eco-friendly future businesses by reinforcing our business portfolio centered on bio-based raw materials,” said Noh Kug-lae, President of LG Chem’s Petrochemical Business.

LG Chem is committed to reaching carbon-neutral growth by 2030 and net-zero emissions by 2050 by managing the impacts of climate change and making positive contributions to society through renewable energy and responsible supply chains.

Headquartered in Seoul, Korea, LG Chem has multiple operation sites worldwide and generated consolidated revenue of KRW 51.9 trillion (USD 42.1 billion) in 2022.

PET recycling – Silicon batteries

-Positive Impact of Technology in Textile Industry

Technology has had a great impact on the textile industry, improving the efficiency and quality of the production process. Some of the most relevant technological innovations in this area are mentioned below:

Automation: The automation of production processes has allowed for greater efficiency and accuracy in the manufacturing of clothing. Automated sewing and cutting machines, for example, can operate at much higher speeds than human workers, allowing for faster and more cost-effective production. PET recycling – Silicon batteries

Digital knitting: Digital knitting is a production technique that uses specialized machines to create intricate patterns and custom designs on fabrics. This technique is ideal for producing high-quality and personalized garments, as it allows for greater precision and detail in design.

3D Printing: 3D printing is increasingly being used in the production of accessories and decorations for garments. This technique allows for the creation of unique and personalized pieces with exceptional precision and quality.

Augmented Reality: Augmented reality is being used to improve the customer experience in clothing and fashion stores. Customers can see how a garment fits without physically trying on it, allowing them to make more informed purchasing decisions.

Smart Fibers: Smart fibers are fabrics that can sense and respond to changes in the environment. For example, some fibers can change color in response to temperature or light, making them ideal for high-tech and sportswear production.

Technology has also had a positive effect on the sustainability of the textile industry. Automation and digitization of production processes have reduced material and energy waste, while smart fibers and high-tech fabrics have enabled the creation of more durable and resistant textiles. PET recycling – Silicon batteries

On the other hand, it has allowed the development of new materials and more sustainable production techniques, such as the use of recycled materials and the production of clothing through processes that are more efficient in terms of water and energy consumption.

-That’s why silicon batteries will lead to the electric boom

Shorter recharge times and more compact battery packs. This is how electric cars will truly become “for everyone”

Range anxiety, long recharging times and high costs are nowadays among the elements that most hinder the diffusion of the electric car. In fact, almost all the manufacturers are working on developing new solutions and technologies capable of solving these problems and thus allowing electric cars to become even more accessible and usable.

This potential “revolution” could come from StoreDot, an Israeli company that has long been working on the development of silicon batteries.

These could guarantee less space in the car and, above all, decidedly reduced charging times. PET recycling – Silicon batteries

160km in 5 minutes

To make these silicon batteries special is the XFC fast charging system which, according to the data declared by the manufacturer, would allow you to recharge 160 km of autonomy in just 5 minutes. The concept is simple: if it is possible to limit the time needed to recharge, a smaller battery can be fitted, thus saving on costs, but also on the weight of the car and consequently improving the range.

Volvo and StoreDot, battery with silicon anode

To date, in fact, to ensure high autonomy, manufacturers fit very large batteries on board their cars which, however, are used to 100% of their capacity only on long journeys, while in all other contexts one is forced to carry behind a large accumulator that is, however, only partially used. At the moment there are 15 manufacturers who are working with StoreDot for the development of this solution, including Volvo.

More efficient and performing

By improving the speed of recharging, StoreDoc proposes to mount smaller batteries on the cars which, consequently, are cheaper to produce and have less impact on the weight of the car. PET recycling – Silicon batteries

To give a practical example, if a 50 kWh battery could be fitted to a car instead of an 80 kWh one, still being able to count on similar performances, a good 200 kg of weight would be saved. Furthermore, by saving 200 kg, range and efficiency would increase and consequently the performance of the car would also improve.

![]()

-The glass packaging crisis: How converting to PET lowers your carbon footprint and reduces your energy costs

The price of energy is skyrocketing, driving up the cost of glass packaging and dramatically reducing supply. With energy costs now 10 to 20 times above typical prices and some glass foundries closing their doors, there is significant risk that soaring energy costs will soon make glass unattainable. PET recycling – Silicon batteries

For brands and producers looking to break free from fluctuating market conditions, PET offers a more reliable long-term supply, a lower carbon footprint, and being 8 to 10 times lighter than glass, drastically reduces logistics, material and production costs.

If you are looking to switch from glass to PET then join our webinar to learn:

- The benefits of PET and why it’s today’s material of choice

- Best practices for converting your existing glass packaging to PET

- Design possibilities and real-life success stories

- How working with Husky can enable a smooth transition