PET Replacing Quartz Sand 06-01-2026 - Arhive

PET Replacing Quartz Sand

Crude Oil Prices Trend

-Replacing Quartz Sand with PET Sand to Create Cementitious Materials

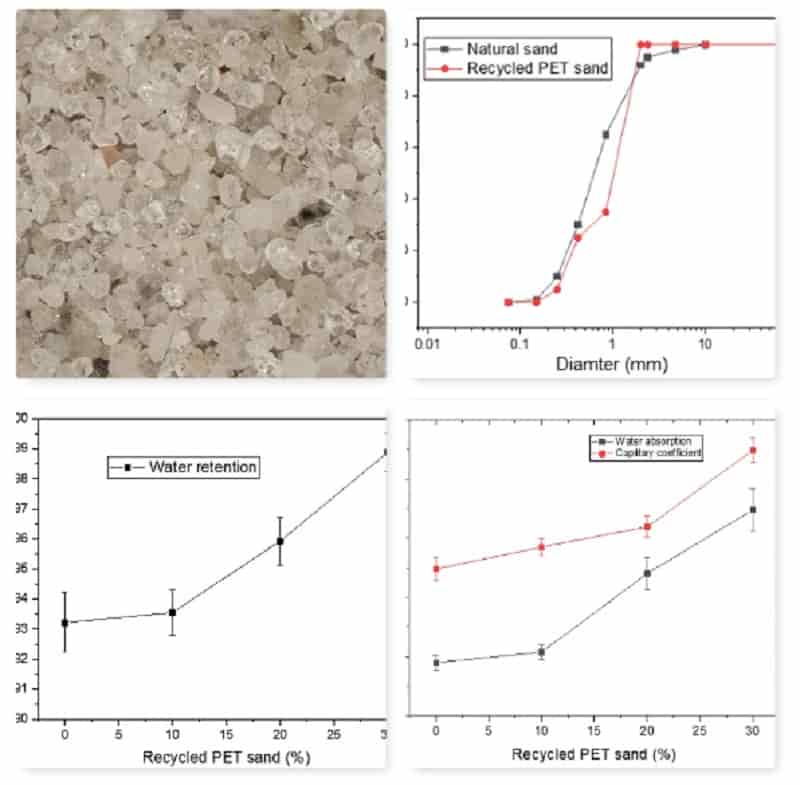

In a recent study published in the journal Materials, researchers from Brazil analyzed polyethylene terephthalate (PET) sand as a replacement of quartz sand at different compositions and measured their compressive strength, flexural strength, density, capillarity, and water absorption.

Researchers found that PET sand is viable up to a content of 10%, which improves the mechanical properties of the mortar and without compromising its workability and incorporated air properties. However, above that the loss of properties is very excessive, especially at 24% it affects its hardenability.

Substitute Sands for Mortars and Portland Cement

Currently, quartz sand from rivers or dunes is used as fine aggregate in concrete and mortar, which is highly harmful to the environment owing to the lack of natural recovery of mineral resources, which are extracted at a much faster rate than they are formed. Also, the calcination of clinks at high-temperature releases harmful gases. PET Replacing Quartz Sand

Many studies have tried to replace natural sand with reinforced concrete demolition (RCD) wastes, vermiculite in geo-polymeric mortars, rock residue in gypsum mortars for the restoration of historic structures, rock residue in cement mortars for block laying and wall cladding, and spherical glass waste particles.

All previous researches indicate that the replacement sand should have adequate granulometry, packing, porosity, and inertness. Adequate particle size reduces porosity, contributing to the packing and mechanical strength, whereas inertness means, it must not interfere with the hydration of the cement and the reaction of other binders.

These factors contribute to mechanical strength, thermal conductivity, hardenability, workability of cementitious materials. PET has shown favorable packing order, ductility, and inertness when used in soil-cement blocks and reinforced polymer composites. PET Replacing Quartz Sand

-Teijin Aramid, Clariter develop chemical recycling solution for Endumax materials

Pioneered process successfully upcycles Endumax composite material, particularly fishing nets, ropes and air cargo containers, into carbon-neutral feedstock for application reuse. PET Replacing Quartz Sand

For more than twenty years, Teijin Aramid (Arnhem, Netherlands), a subsidiary of the Teijin Group, has been recycling Twaron fibers in its own recycling facilities (“Teijin Aramid program produces bio-based, high-performance aramid fibers” details one such initiative). In the quest to zero emissions, Teijin Aramid has joined forces with recycler Clariter (Siyakha, South Africa) and pioneered a sustainable solution in chemical advanced recycling for Endumax, an ultra-high molecular weight polyethylene (UHMW-PE) material. Together, the companies are said to be developing a sustainable, disposal method for high-value, post-production and end-of-life (EOL) material that is difficult to recycle mechanically.

Initial tests performed on Teijin Aramid’s Endumax feedstock were carried out at Clariter’s operational pilot plant in Gliwice, Poland. The results determined that samples of fishing nets, ropes and air cargo containers are suitable materials for chemical recycling. High-resistance UHMW-PE, which Teijin Aramid says was once problematic to recycle, has been now successfully upcycled into feedstock using this recycling process into pure, crude-free industrial products with thousands of applications such as cleaning agents, degreasers, paints and specialty wax.

“Working with a partner like Teijin Aramid and proving that chemical recycling is the solution for the plastic waste epidemic, brought us again a bit closer to the cleaner and more sustainable future,” says Jasper Munier, Clariter business development manager for northwest Europe. PET Replacing Quartz Sand

“As a next step, we want to process samples of much larger quantities and types at our 15,000-square-meter industrial-scale plant in East London, South Africa. We look forward to working with Teijin Aramid’s team of experts and positioning chemical recycling as an irreplaceable recycling solution.”

–Bottle grade PET Petrochemicals Monoethyleneglycol MEG Paraxylene

-Replacing Quartz Sand with PET Sand to Create Cementitious Materials

–Teijin Aramid, Clariter develop chemical recycling solution for Endumax materials

–Faerch acquires dairy packaging company to boost circularity

–Piana Technology to Unveil E/SMART Nonwoven Fiber Technology

–Teijin begins life-cycle analysis of its carbon fibers

-New ALPLA partnership to focus on development of cellulose-based closures

–UAE-based textile division of ARISE IIP joins ITMF

PET Replacing Quartz Sand