PETBottlesRecycling Hydrogen Chemicals 11-05-2021 - Arhive

PETBottlesRecycling Hydrogen Chemicals

Crude Oil Prices Trend

-Malaysia removes anti-dumping tariffs on Korean PET

The Malaysian government has decided to reverse its preliminary decision to impose anti-dumping tariffs on Korean polyethylene terephthalate products, according to industry officials on Sunday.

After an investigation, Malaysia’s Ministry of International Trade and Industry recently concluded that PET products imported from Korea will not damage the country’s oil and chemical industries, and decided to lift the temporary anti-dumping tariffs, according to industry sources here.

According to a preliminary decision made in December, the Malaysian government sought to slap anti-dumping tariffs of 15.5 percent on PET products exported by several Korean companies, including SK Chemicals and TK Chemical, after a Malaysian company Recron filed a petition to the government in June.

The two Korean companies reportedly export about 10,000 metric tons of PET to Malaysia, annually.

Recron had claimed that the imports of the PET products from six countries, including South Korea, China, Japan and the US, were being dumped into Malaysia at a price much lower than the selling price in the countries’ domestic markets, causing material injury to Malaysian market.

-Commodities of the future: Blue, green hydrogen key to the energy transition – report

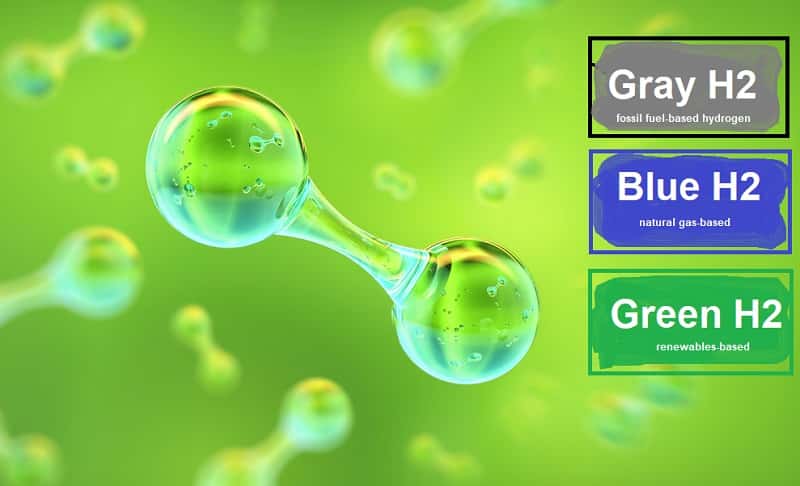

While fossil fuel-based hydrogen (grey hydrogen) as a fuel is not new, blue hydrogen (natural gas-based) and green hydrogen (renewables-based) are entering commercialisation and are only just becoming established in energy commodity markets, market analyst Fitch Solutions notes in its latest industry report on the commodities of the future. PETBottlesRecycling Hydrogen Chemicals

In fact, the ‘hydrogen as a commodity’ story has just started to unfold, with a notable rise in interest seen since 2020, and the sector will evolve at a fast pace in the coming years amid an ever-expanding project pipeline, Fitch says.

Low carbon hydrogen has numerous potential industrial applications to decarbonise multiple sectors including power, or as fuel for manufacturing, transportation, and more.

Fitch forecasts green hydrogen production will rapidly accelerate and gain increasing market share at the expense of traditional grey hydrogen, rising from less than 1% of current global market supply to a forecast 10% by 2030. This rapid acceleration has been brought forward by declining renewable costs, wide geographical scope, short development times and its zero-carbon footprint, Fitch says.

-Romanian recycler turning 2bn PET bottles into polyester fibre

Green Fiber, part of the Green Group family, has announced that the business is transforming over 2 billion polyethylene terephthalate (PET) bottles each year into sustainable polyester staple fibre products for various industries. Green Fiber’s 100 per cent recycled polyester fibres produce 50 per cent less C02 emissions than virgin fibre alternatives. PETBottlesRecycling Hydrogen Chemicals

Romania-based recycler and producer Green Fiber works in tandem with its sister company Green Tech, a prominent recycler in Europe, to recycle PET bottles, it said in a press release.

With an increased focus worldwide by businesses on reducing their carbon footprint and promoting a more sustainable image, Green Fiber’s 100 per cent recycled products offer a diverse range of industries such as hygiene, home textiles and more, the opportunity to confidently state that they are seriously committed to reducing their carbon footprints.

“As part of our regenerative role of both producer and recycler, we are proud to recycle over 2 billion PET bottles a year which are then transformed into sustainable fibres for an array of crucial industries. Furthermore, as we are the largest producer of 100 per cent PET recycled fibres in Europe with a range of products emitting 50 per cent less in C02 emissions compared to virgin fibre alternatives, we believe it’s now essential for sustainable

-Shandong Yulong Petrochemical Selects Lyondell Basell Technology

Lyondell Basell’s Lupotech T high-pressure polyethylene technology will be used in two separate production lines at Shandong Yulong Petrochemical Co.’s new facility in China. The production lines include a 200 KTA low density polyethylene line as well as a 300 KTA LDPE and ethylene vinyl acetate copolymer line which will be used to produce LDPE with vinyl acetate comonomer.

Lyondell Basell has announced that Shandong Yulong Petrochemical Co. will use the Lyondell Basell Lupotech T high-pressure polyethylene technology in two separate production lines at a new facility. PETBottlesRecycling Hydrogen Chemicals

The process technology will be used for a 200 KTA low density polyethylene (LDPE) line and a 300 KTA LDPE and ethylene vinyl acetate copolymer (EVA) line to produce LDPE with vinyl acetate comonomer. The facility will be located in Longkou, Yantai, Shandong Province, P.R. of China.

-PolystyreneLoop inaugurates a new plant in June

The installation of the equipment is nearing completion and we placed 400 m2 of flooring for our EPS and XPS storage. All three outdoor silo’s for Loop-PS are installed and give an exciting new look to the plant. The solvent is ordered and we cannot wait to fill up our “big Berta” – the biggest vessel in the entire plant.

We are happy to announce that we now also have a third HUB in the Netherlands! Kingspan Unidek in Gemert. Kingspan Unidek is traditionally an EPS converter, but they took upon themselves to also offer a solution for PS-foam waste coming from demolition and renovation projects. PETBottlesRecycling Hydrogen Chemicals

We hope that this will serve as inspiration for others. We translated the Position Paper on the collection of HBCD-containing PS-foam waste in Dutch and discussed it with national ministries. In parallel we are collaborating with VERAS – the Dutch demolition association – on a project to collect the waste appropriately and have it pre-treated by our HUBs

-Plastics and masterbatches in automotive wire industry

Market tendencies for automotive wires

The automotive market is changing. Since 1885, with the first internal-combustion car, this kind of engine is the dominant.

Market is evolving each day, specially accelerated for Covid-19 crisis, revolutionised with more sophisticated electronic systems and pushing for electric cars in parallel with self-driving cars. PETBottlesRecycling Hydrogen Chemicals

In 2019, 4.8M of electric vehicles were in use, more than 50% in China. Targets of reduction of the air pollution emissions and the stronger environmental sensibility by the users also help to increase this electrical car registration trend.

This tendency translates into the automotive parts manufacturers to provide more lighter and higher performing components, also in wire automotive industry. That means that new materials and formulations will satisfy these demands.

-Unimodal HDPE for Blow Molded Bottles Boasts a ‘Step Change’ in ESCR

ExxonMobil’s new unimodal HDPE is said to represent a big leap in ESCR performance without compromising other properties. PETBottlesRecycling Hydrogen Chemicals

A new unimodal HDPE for blow molded bottles and containers developed by ExxonMobil Chemical is touted as a step-change in ESCR (Environmental Stress-Crack Resistance) without compromising stiffness, impact, top-load or processability.

ExxonMobil says its Paxon HDPE SP5504 represents a paradigm shift in properties normally associated with currently available unimodal HDPEs, suiting it to household and industrial chemical (HIC) bottles and containers for products like bleach, wipes, and agricultural chemicals, according to Dr. James Stern, business-development manager for North America & EMEAF.

-New project from Fraunhofer hopes to pave the way for new plastics recycling methods

Seven Fraunhofer Institutes are pooling their expertise in the lighthouse project “Waste4Future”, which aims to increase energy and resource efficiency in the use of plastics and thus pave the way for a chemical industry that requires fewer fossil raw materials and produces fewer emissions.

A key part of the project will be to create new opportunities for recycling plastics in order to make the carbon they contain available as a “green” resource for the chemical industry. PETBottlesRecycling Hydrogen Chemicals

“We are paving the way for a carbon circular economy in which valuable new base molecules are obtained from plastic waste and emissions are largely avoided: Today’s waste becomes tomorrow’s resource,” says Dr.Ing. Sylvia Schattauer, deputy director of the Fraunhofer Institute for Microstructure of Materials and Systems IMWS, which is heading the project.

-HHI to Build Pilot Green Hydrogen Production Plant in East Sea

Hyundai Heavy Industries (HHI) announced on May 6 that it has signed an MOU with nine organizations to set up 100 MW green hydrogen production facilities in a floating wind farm in the East Sea.

The nine organizations included the Ulsan City Government, Ulsan Techno Park, the Ulsan Chamber of Commerce, SK Gas, Korea East-West Power, Sejin Heavy Industries, and the UNIST. PETBottlesRecycling Hydrogen Chemicals

Under the MOU, the first phase of the project is to build a 100 MW green hydrogen pilot plant in a floating wind farm in the East Sea by 2025. Their second-phase project is to build a 1.2 GW large-scale green hydrogen production plant by 2030.

HHI is planning to develop a large-scale hydroelectric green hydrogen plant that produces hydrogen from seawater using electricity supplied by the floating wind farm.

-Mechanical Recycling vs Chemical Recycling

Recycling plastics for use in new packaging makes a positive impact on the environment. There are two main types of recycling: mechanical and chemical. Let’s take a look at how these processes differ. PETBottlesRecycling Hydrogen Chemicals

In mechanical recycling, varying plastic types enter into the recycling process. The plastics go through grinding, resulting in flakes of plastic which are then washed and separated (e.g., the plastic used for lids is separated from the PET plastic used to make bottles because they are different type of plastics). The flakes are then melted into small pellets, which will be used to make new products.

Chemical recycling, defined by This is Plastics (www.thisisplastics.com), is any process by which a polymer is chemically reduced to its original monomer form so that it can eventually be processed (re-polymerized) and remade into new plastic materials that go on to be new plastic product. When an item cannot be recycled mechanically due to colorants, barriers, or multilayers, chemical recycling may be an option.

PETBottlesRecycling Hydrogen Chemicals