Petrochemical Automotive Nylon CrudeOil 25-11-2020 - Arhive

Petrochemical Automotive Nylon CrudeOil

Crude Oil Prices Trend

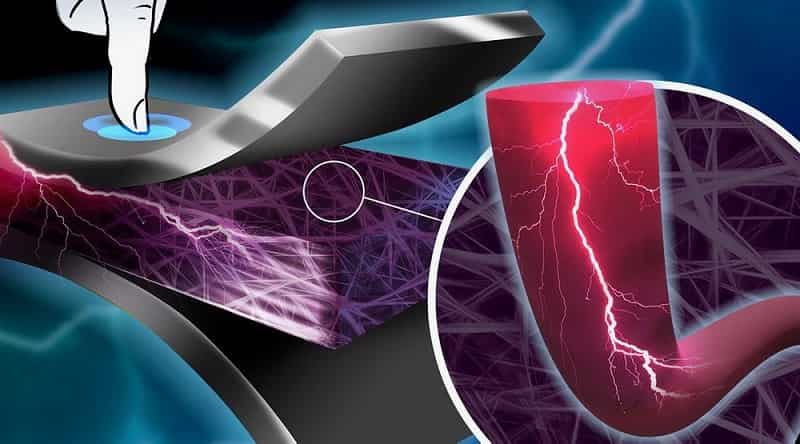

-Nylon fibers hold promise for electricity-generating clothing

The research could result in garments that can power mobile phones and more

Scientists have found a way to produce nylon fibers that can produce electricity through simple body movements, giving rise to the idea of clothing that could power a phone or health-monitoring device.

The findings by researchers from the University of Bath, the Max Planck Institute for Polymer Research in Germany and the University of Coimbra in Portugal explores the use of solution-processed piezoelectric nylon.

“There’s a growing demand for smart, electronic textiles, but finding cheap and readily available fibers of electronic materials that are suitable for modern-day garments is a challenge for the textile industry,” said Kamal Asadi, professor from the University of Bath department of physics.

-Altium Packaging buys blow molder SFB Plastics

Founded in 1970 as a provider of thermoformed plastic freezer spacers, SFB Plastics company expanded into rigid packaging in 1976 and has specialized in HDPE blow molding of industrial containers for over 40 years. Petrochemical Automotive Nylon CrudeOil

U.S.-based blow molder Altium Packaging LP has acquired the assets of SFB Plastics Inc., in Wichita, Kansas, a privately-held material handling and packaging manufacturer, specializing in HDPE blow molding of industrial containers.

Atlanta-based Altium is a unit of publicly traded Loews Corp.

The financial terms of the deal have not been disclosed.

Founded in 1970 as a provider of thermoformed plastic freezer spacers, SFB Plastics company expanded into rigid packaging in 1976 and has specialized in HDPE blow molding of industrial containers for over 40 years.

-Lenzing rolls out traceability platform for Tencel, Ecovero fibers

The first phase of the blockchain-enabled system is onboarding now in South Asia, followed by China and Turkey in early 2021 Petrochemical Automotive Nylon CrudeOil

Lenzing, Austria – Following several successful pilot programs, Lenzing has launched a blockchain-enabled traceability platform for its Tencel and Lenzing Ecovero branded fibers.

The platform is powered by Hong Kong-based start-up TextileGenesis and ensures the traceability of textiles from fiber to production to distribution. The global roll-out will be conducted in phases, with the first phase, expected to be completed within the fourth quarter, encompassing Lenzing’s supply chain partners in India, Bangladesh, Pakistan and Sri Lanka. An estimated 300-plus supply chain partners from China and Turkey will join the program in the first quarter of 2021, with the expectation that most eligible Lenzing partners will be onboarded by the second quarter.

-IIT Guwahati develops method to turn industrial waste into chemicals

The findings of the time have also been featured in the Royal Society of Chemistry journals–Chemical Communications and Catalysis Science and Technology

Researchers at Indian Institute of Technology (IIT), Guwahati, have formulated efficient “pincer” catalytic systems that transform industrial or biomass wastes into valuable chemicals. Petrochemical Automotive Nylon CrudeOil

According to the team, tiny amounts of these “pincer catalysts” repeatedly convert large amounts of industrial waste such as glycerol into lactic acid and hydrogen. Such catalysts also efficiently convert bioethanol, a low-energy density fuel, into high-energy density butanol.

“Pincer catalysts are complex molecules in which, an organic moiety holds on tightly to a metal core, much like the claws of a crab. Such an arrangement not only confers stability to the catalyst, but also selectivity to bring about the intended transformations,” said IIT Guwahati professor Akshai Kumar Alape Seetharam.

-Kelheim Fibres Partner of ETP in „Bio-Based Fibres“ and “Circular Economy” programs

The goal is to bring key players from industry and science together to develop a long-term strategy to shape the sustainable realignment of the European textile industry

The Bavarian viscose speciality fibres manufacturer Kelheim Fibres has partnered with the European Technology Platform for the Future of Textiles and Clothing (ETP) in two strategic programs: “Bio-Based Fibres” and “Circular Economy”.

Against the backdrop of the increasingly important sustainability debate, fundamental changes inside the textile supply chain are taking place. The two three-year ETP programmes “Bio-Based Fibres” and “Circular Economy” are a clear response to this. The goal is to bring key players from industry and science together to develop a long-term strategy to actively shape the sustainable realignment of the European textile industry.

“We have been manufacturing bio-based fibres for almost 85 years – these fibres are made from the renewable material wood and they are fully biodegradable at the end of their product lifecycle. Petrochemical Automotive Nylon CrudeOil

As an alternative to crude-oil based materials, these fibres are becoming increasingly popular in various applications.

-India halts MEG anti-dumping investigation

India’s ministry of commerce and industry has halted its anti-dumping investigation into ethylene glycol (MEG) after receiving a withdrawal request from the applicants.

Indian private-sector refiner and petrochemical producer Reliance Industries (RIL), the key applicant, had requested on 18 November to withdraw the probe for unspecified reasons. But it still has the option to resubmit an application to relaunch the investigation.

The Indian government had started an anti-dumping investigation into imports of MEG under HS code 29053100 from Saudi Arabia, Kuwait, Oman, UAE and Singapore in December 2019. RIL then in late February made a request to the authorities to exclude Saudi Arabia from the investigation. Petrochemical Automotive Nylon CrudeOil

-BTB PET Recycling further increases capacities

During the Corona Lockdown in spring 2020 German PET recycler BTB PET-Recycling GmbH & Co. KG installed a new preheating unit and another SSP reactor supplied by Starlinger recycling technology. Petrochemical Automotive Nylon CrudeOil

The PET bottle-to-bottle recycling company based in Bad Salzuflen, North Rhine- Westphalia, is now operating 9 SSP (Solid State Polycondensation) reactors from Starlinger recycling technology. BTB has been using the food-grade technology developed by the Austrian specialist for plastics recycling since 2007.

Each year, BTB processes approximately 20,000 tons of PET input material from the German bottle return system on a Starlinger recoSTAR PET 165 iV+ recycling line installed prior to the SSP reactors. Andrzej Zajontz, one of BTB’s General Managers and in charge of all technical matters, explains why this is not as easy as it used to be: “Unfortunately, the beverage containers collected through the German container deposit system are not as well separated as before – in the reverse vending machines both clear and coloured bottles are collected together, and that is how they are delivered.

-German industry expectations fall as second wave stalls recovery

German manufacturing business conditions remained positive in November but expectations for the coming months “turned notably less optimistic”, according to the Ifo Institute on Tuesday.

The survey conducted by Ifo among German companies’ managers showed expectations for the coming months are equally pessimistic in other sectors like services or construction. Petrochemical Automotive Nylon CrudeOil

Germany’s strong industrial base accounts for around 20% of the country’s economic output; its chemicals industry is the largest in Europe, with €193bn in sales in 2019 employing around 450,000 people.

“This month’s [November] bright spot is manufacturing. The business climate improved here, with companies assessing their current situation as markedly better. Incoming orders rose, albeit more slowly than last month,” said Ifo.

“However, expectations for the coming months turned notably less optimistic.”

-Braskem and Haldor Topsoe achieve first production of bio-based MEG from sugar

Braskem, the largest petrochemical company in the Americas and a world leader in the production of biopolymers, and Denmark-based Haldor Topsoe, a global leader in supply of catalysts, technology, and services for the chemical and refining industries, have announced that they achieved their first-ever demo-scale production of bio-based monoethylene glycol (MEG), reported CISION.

As a result of the collaboration between the two companies, the MOSAIK technology development has been progressing according to schedule at the demonstration unit located in Lyngby, Denmark. Petrochemical Automotive Nylon CrudeOil

The demonstration unit was started up in 2019 with the primary goal to demonstrate all key design features of the pioneering technology that transforms sugar into renewable MEG. Since then, the remaining process units of the plant have been built and put into operation, and the production process has been optimized.

-Gerresheimer: More space for the Small Batch Production of plastics

Gerresheimer is expanding the production area for Small Batch Production of plastics in Wackersdorf – Gerresheimer Regensburg is increasing the capacity of its Small Batch Production in the Technical Competence Center (TCC) Wackersdorf. To this purpose, already existing production area has been converted into clean room space, and a new building with additional clean room and office space has been completed. The company is reacting with the expansion of production space in keeping with the growing number of projects that require smaller numbers of units or for which a smaller number of complete products are already required prior to large batch production for development, approval, and industrialization. Petrochemical Automotive Nylon CrudeOil

Gerresheimer had already invested a double-digit sum in the millions in the expansion of Small Batch Production in Wackersdorf in 2018. In the context of the plastic and glass competence of the company, 900 square meters of additional area was at that time created for the development and industrialization of glass products like syringes and carpules.

-New Upstream Innovation guide offers practical solutions to the plastic pollution crisis

The company published Upstream Innovation: A guide to packaging solutions, a practical guide to eliminating plastic pollution through circular economy solutions.

Packed with practical guidance and real-world examples, this handbook has been designed for anyone directly or indirectly influencing the packaging that is put around a product.

By focusing more of their efforts on upstream innovation – at the design stage of a product rather than just downstream efforts such as recycling – businesses can prevent waste from ever being created in the first place. Petrochemical Automotive Nylon CrudeOil

Petrochemical Automotive Nylon CrudeOil