Petrochemical Automotive PET CrudeOil 23-11-2020 - Arhive

Petrochemical Automotive PET CrudeOil

Petrochemical PETBottle PSF Polymers Trend

Crude Oil Prices Trend

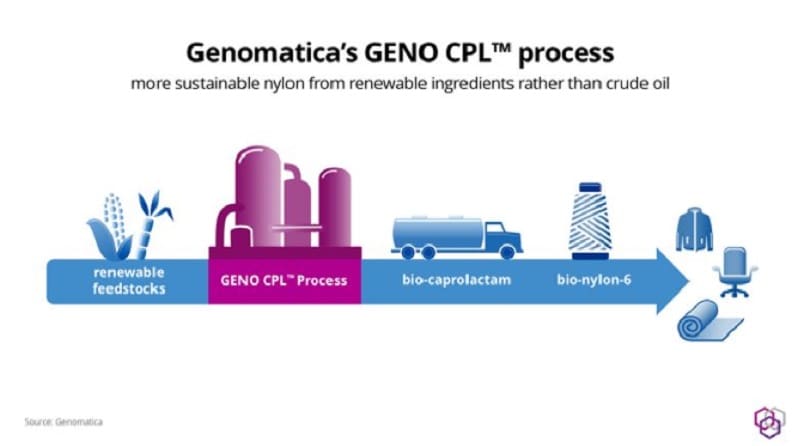

-Genomatica & Aquafil Form Partnership to Produce Renewable Nylon-6

San Diego, CA, November 20, 2020-Genomatica signed a first-of-its-kind deal with Aquafil to build a demonstration scale facility to produce the largest quantity of 100% renewable nylon-6 ever available. Responding to surging consumer interest in sustainable products, the material will go to leading global brands eager to explore and develop renewable products, create showcase goods and test feedback with customers. The deal is a 50-fold expansion over previous production levels and represents significant acceleration toward commercializing renewably-sourced nylon-6, a material that is poised to reshape a $960 billion textile industry.

This multi-year agreement provides the foundation for a more sustainable nylon value chain by expanding a longstanding Genomatica partnership with major European nylon producer Aquafil. The two companies teamed up in January 2020 to produce the world’s first ton of bio-nylon-6 precursor at pilot scale. Relying on their expertise in scaling up renewably-sourced chemicals, Genomatica and Aquafil are moving directly to a larger-than-typical demonstration scale to support initial commercial applications by committed brand partners. The first production runs are slated to create 50 tons of bio-nylon for pre-commercial use by Genomatica’s brand partners, with the demonstration plant to continue supporting product needs until commercial scale plants are in operation.

Neste, the world’s leading producer of renewable diesel and sustainable aviation fuel and a forerunner as a provider of renewable and circular solutions for the petrochemical industry, and LG Chem, South Korea’s largest diversified petrochemicals company and a world’s leading manufacturer of lithium-ion batteries for energy solutions, have today announced their aim to build a strategic long-term partnership to develop and grow the biopolymers and biochemicals market globally, and more specifically, in the LG Chem’s home market Korea.

Thanks to the partnership, LG Chem will start replacing fossil feedstock commonly used in the manufacturing of polymers and chemicals with Neste Renewable Hydrocarbons in the upcoming months. This helps LG Chem to produce renewable polymers and chemicals to meet the increasing sustainability requirements and expectations of its customers – such as those producing polyolefin-based containers, packaging, hygiene products, and electronic materials – without compromising on quality, performance or recyclability of its products.

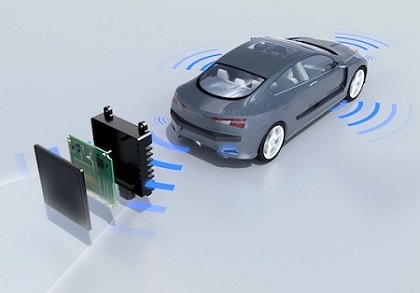

-Ultradur RX provides more clarity for radar sensors

The development of new technologies for the automotive industry focuses on comfort and the safety of passengers. Chemistry has already made a decisive contribution to this and will also play an important role in future mobility challenges. In addition to electromobility, automated driving is a crucial building block for the mobility of tomorrow. Closely linked to this development is the increased use of sensors.

With Ultradur RX, BASF has now developed a modified polybutylene terephthalate (PBT) specifically for radar sensor applications in vehicles. Due to its good resistance against media such as splash water, oils or salt, Ultradur offers an exceptional protection for sensor housings. In addition, the new material shields the sensitive electronics in the housings against disturbing electromagnetic waves from other vehicles

Dr Erik Gubbels, R&D Ultradur expert in the Performance Materials division at BASF, said: “The different grades of the new Ultradur RX series are products designed for absorption and reduction of interference radiation in the range of 76 to 81 GHz. They offer a high level of protection of the sensitive electronics. This dielectrically optimized material fulfills the high standards for sensor components and is suitable for the use as a rear housing cover or behind the printed circuit board of a radar sensor, for example.”

-NPP “POLYPLASTIC” invests in the expansion of the production of compounds

NPP POLYPLASTIC, the largest Russian manufacturer of thermoplastic composite materials, in 2021 will commission two high-performance compounding lines for plastics based on twin-screw extruders of the BluePower series, the company said in a press release.

NPP “POLYPLASTIC” in 2021 will commission two high-performance plastic compounding lines based on twin-screw extruders of the BluePower series. KraussMaffei Extrusion GmbH (Germany) will supply under the contract. The planned capacity of the new lines, which have no analogues in Russia today, will be more than 20 thousand tons of finished products per year.

High-tech lines will be installed within the framework of the investment project of NPP “POLYPLASTIC” for the creation of the “Saratov plant of polymer materials” (SZMP) on the territory of the region of the same name and increasing the production capacity of the enterprise. Investments in equipment alone will amount to over EUR3.3 million.

“The dynamics of growth in demand for compounds has not dropped below 6% per year in recent years, markets for thermoplastic elastomers, heat and electrical conductive compounds, and the cable business are actively developing in our country. These are the very niches that Russian manufacturers can and should occupy, displacing imports.” , – believes the managing partner of NPP POLYPLASTIC Andrey Menshov.

-Sinopec Raises PP Prices in South China

Large Chinese manufacturer Sinopec significantly increased its PP price offer in southern China on November, a source close to the company told ICIS .

The South China branch of the petrochemical giant increased its offers by CNY100-350 per tonne to CNY8 650-9 100 per tonne for PP for filaments and fibers, by CNY200-350 per ton to CNY8 800-9,500 per ton for injection molded PP and CNY100 –250 per tonne to CNY9,000–9,600 per tonne for some PP copolymers.

Meanwhile, PP prices for filaments / fibers and biaxially oriented polypropylene (BOPP) are increased by CNY150 per tonne to CNY8,900 per tonne and CNY8,750 per tonne, respectively.

The sharp rise in polypropylene futures and limited supply were the main reasons for the rise in prices.

The January 2021 contract, the most actively traded polypropylene futures contract on the Dalian Commodity Exchange (DCE), was up 2.06% on Nov.16, compared to the previous settlement.

According to market sources, Sinopec and PetroChina’s combined stocks of polyolefins were 630 thousand tonnes as of November 17, down 50 thousand tonnes from November 16 and 12% year-on-year.

-Plastic industry under pressure from import competition

THE plastics industry is under pressure from import competition at a time of global surpluses for the segment, as well as reduced activity during the lockdown, the industry association said.

Philippine Plastics Industry Association, Inc. President Danny Ngo said lockdown measures have reduced production by constraining the movement of personnel and supplies, especially during the initial months of the public health emergency.

The plastics industry produces mostly pipes and packaging, supplying the food, agriculture, and electronics industries.

The pandemic has increased the global use of plastics as demand for medical goods and take-out containers surged, while the collapse of the oil market made virgin plastic manufacturing cheaper than recycling, alarming environmental advocates.

In the Philippines, importers have the upper hand.

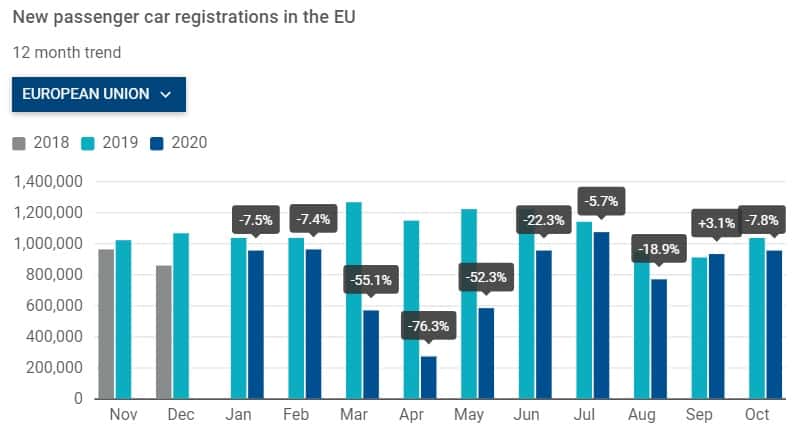

-Passenger car registrations: -26.8% 10 months into 2020; -7.8% in October

Brussels, 18 November 2020 – In October 2020, the EU passenger car market slipped back into negative territory, after posting the first increase of the year in September. Registrations of new cars declined by 7.8% to 953,615 units last month, as several European governments reimposed restrictions to battle a second wave of the coronavirus.

In October 2020, the EU passenger car market slipped back into negative territory, after posting the first increase of the year in September. Registrations of new cars declined by 7.8% to 953,615 units last month, as several European governments reimposed restrictions to battle a second wave of the coronavirus. With the exception of Ireland and Romania, losses were posted in all EU markets, including the four major ones. Demand fell markedly in Spain (-21%) while more moderate decreases were observed in France (-9.5%) and Germany (-3.6%). In Italy, on the other hand, demand remained almost unchanged (-0.2%) compared to October 2019 levels.

-Mini Vision Urbanaut concept starts with the interior

Mini has released its Vision Urbanaut concept, which the company claims has been designed from the inside out.

The designers completed the interior concept before developing the exterior, using floor plans, pieces of furniture plus wooden scale models to provide an indication of size. Over the course of the project, augmented reality was employed to create a digital model, which was then systematically optimized.

At 4.46m in length, the concept provides an interior space that can be used in different ways and offers ease of movement inside the car, Mini says. For example, it can transform into a living room and occupants enter the cabin through a single, large sliding door in the side of the car; there are no other doors on the driver’s side or front passenger side.

-UKRI invests £20m to tackle plastic waste in developing countries

Plastic pollution is one of the world’s biggest environmental challenges. This investment by UKRI aims to reduce its impact on communities and the environment by supporting interdisciplinary research teams to investigate ways to combat or mitigate the effects of plastic waste in developing countries.

An investment of £20 million will support interdisciplinary research that aims to improve understanding of the impacts of plastic pollution in developing countries.

The research projects will draw upon arts and humanities, economic and social, engineering, physical, environmental and life sciences to explore ways to mitigate the impacts of plastic pollution, to enable cleaner and more resilient and productive environments and support economic growth and societal wellbeing.

Petrochemical Automotive PET CrudeOil