Petrochemical AutomotiveIndustries R-PET 09-01-2021 - Arhive

Petrochemical AutomotiveIndustries R-PET

-Sulzer Chemtech to supply lactide processing technology to Chinese project

Sulzer Chemtech has won a contract to supply lactide production equipment to a project at Zhejiang Depei New Material Co.’s latest plant in Ningbo, Zhejiang province, China.

The processing equipment will enable the company to produce large volumes of high-quality lactide from plant biomass. The plant will leverage an innovative hybrid technology to reach high purity levels, resulting in outstanding thermal and mechanical properties.

The project in Ningbo of Zhejiang Depei New Material, a subsidiary of Zhejiang Youcheng New Materials, is part of the company’s strategy to support the large-scale adoption of sustainable plastics and fibers made from renewable resources, such as biomass from agricultural processes.

-Views on caprolactam market trend in January 2021

On December 24th 2020, Sinopec settled the December contract for caprolactam at 11,700yuan/mt, up 1,050yuan/mt or 9.9% month-on-month. Many downstream users said that the settlement was too high. In fact, in comparison with CPL spot (11,750yuan/mt on Dec 24), the settlement was in line with market expectation, at least not too unreasonable.

Contract rise is also in line with CPL spot market movement and benzene contract settlement. Due to previous intensive plant maintenance, CPL supply had been very tight in the middle of the month and prices were soaring up high to 11,850yuan/mt, which was not acceptable for traditional nylon 6 chip makers. But some cord fabric plants had taken some orders at 11,800-11,900yuan/mt or above, as cord fabric market hiked on bullish demand. Rising spot market pushed up the natural average CPL spot rate in Dec and thus finally made settlement as high as 11,700yuan/mt. This rate was also in line with the increase in Sinopec’s benzene contract settlement for Dec, which rose 603yuan/mt or 15.6% month-on-month. The cost increase takes around 57.4% of CPL contract settlement increase.

-Specialized Packaging Group bought by investment firm Altamont Capital Partners

Baldwinsville, N.Y.-based SPG manufactures protective packaging products that operates under two divisions, Ivex and Engineered Packaging.

Private investment firm Altamont Capital Partners has acquired Specialized Packaging Group Inc. (SPG), said to be one of the largest independent manufacturers of protective packaging in North America, from Paul Gaulin, the company’s founder.

The financial terms of the deal have not been disclosed.

As part of the transaction, Gaulin is retiring as president and CEO of SPG, but will remain a member of the board of directors and a minority investor in the business.

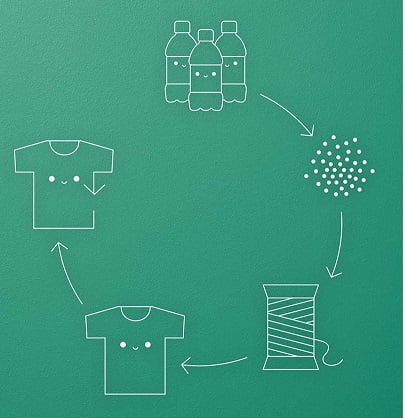

-H&M and Danone AQUA turns PET plastic into comfy kids wear

Swedish fashion brand H&M has in collaboration with Danone AQUA, Indonesia’s number one water bottled brand turned PET plastic into colorful and comfortable kids wear.

The project ‘bottle2fashion’ initiated in September 2020 is a response to the Indonesian government to lessen ocean pollution as well as creating more jobs. Indonesia is on a mission to tackle its huge plastic pollution problem and aims to cut marine plastic waste by 70% in 2025.

From this initiative, locals collected more than 3.5 million PET plastic bottles on the islands of Indonesia, cleaned them, and crushed them into small pieces. The small pieces were then made into polyester fabric fibers and combined with organic cotton and other types of recycled cotton to create comfortable hoodies, jogger pants, and colorful long sleeve t-shirts for the bottle2fashion collection.

Nellie Lindborg, H&M sustainable manager says that with the project they want to be involved with cleaning the beaches and the oceans. The bottle2fashion project is an incorporation with other companies, as part of their initiative to move towards circular economy. The project aims to find alternatives to conventional polyester, which is also a kind of plastic, to make more sustainable and affordable clothes for kids and overall to improve the environment, the economy and the livelihood in Indonesia.

-Sparsh produces high barrier CPP films using Bobst’s AluBond

Sparsh Industries aggressive expansion plan in the coming years

Sparsh Industries is the first company in India to have the Bobst AluBond process on a wide web machine and is achieving excellent barrier properties as a result. The Expert K5 3300mm-wide metallizer was commissioned in June 2020 and is producing metalized CPP with an oxygen barrier of less than 10 cm3/(m2 d) and a water or moisture barrier of less than 0.50 g/(m2 d). The AluBond process enables substrates to achieve higher bond strength results without any modification. The PSA desk has slightly edited the interview submitted to us by Bobst Manchester in the United Kingdom, mainly for style.

Bobst’s long relationship with Sparsh, based in Kanpur in North India, exceeds a decade. In these years, four of its metallizers have been installed and commissioned at Sparsh. Incorporated in 2009, Sparsh Industries is a well-known and reputed manufacturer of polyester and metalized films marketed under its ‘SPARSHPET’ brand. With its metalized films available in numerous optical densities for various applications, Sparsh also manufactures CPP films, customized holographic film and paper, offline coated products, and polyester resins.

The company has advanced R&D and testing facilities for process innovation and product development. In a major expansion mode, Sparsh Industries is developing an aluminum foil rolling plant and an additional polyester film and polymer plant. Ashutosh Agarwal, CEO of Sparsh Industries, is extremely satisfied with how the new metallizer is running, and we decided to speak to him to find out more.

-Biodegradable plastics will not solve the plastic problem

Biodegradable packaging will not solve China’s plastic crisis, according to a report published by Greenpeace East Asia.

China’s biodegradable plastics industry has seen a huge growth in recent years, driven by legislation to ban several types of single-use plastics.

As of this year, 36 companies have planned or constructed new biodegradable plastic manufacturing facilities in China.

According to the report, if this rush to produce biodegradable plastics continues, China’s e-commerce industry is estimated to produce 5 million tonnes of biodegradable plastic waste per year by 2025.

The authors of the report have highlighted that the term ‘biodegradable plastic’ can be very misleading.

The majority of biodegradable plastics only degrade within six months in controlled compost facilities at temperatures as high as 50 degrees Celcius and carefully managed humidity conditions. Under typical conditions such as landfill, the biodegradable plastics can remain intact for much longer than six months.

-Blast at Chinese Recycler Shows Battery Supply Chain Risks

- Explosion occurred Thursday at factory in China’s Hunan

- Local government says one person killed, six seriously injured

China’s biggest battery manufacturer has urged a focus on safety issues after an explosion at a recycling affiliate, which has drawn attention to the risks in the industry’s supply chain.

The blast at a Hunan Brunp Recycling Technology Co. factory in Hunan province killed one person and seriously injured six others, the local government said on its official Weibo. Hunan Brunp is a unit of Guangdong Brunp Recycling Technology Co., a subsidiary of Contemporary Amperex Technology Co.

-Henkel CSR Contributes to Circular Economy and Climate Protection

Henkel has reached a milestone in its engagement for sustainable packaging: The company used almost 700 million bottles made of 100% recycled plastics for Laundry & Home Care products in Europe – more than 400 million alone in 2020.

The recycled material stems from post-consumer waste, including Social Plastic from Henkel’s partnership with the Plastic Bank. By increasing the number of packaging made of recycled material, Henkel not only contributes to a circular economy but also to climate protection: Recycled PET has an almost 80% lower CO2 footprint compared to virgin plastic.

“At Henkel, we promote sustainable packaging solutions and foster a circular economy along the value chain – because we are committed to live up to our responsibility as a consumer goods manufacturer,” said Abdullah Khan, head of Packaging Sustainability Laundry & Home Care at Henkel. “We are increasing the share of recycled material across our entire portfolio and many packaging includes recycled plastics already. It is not always possible to advance to 100% – also due to the limited availability of high-quality material. Nevertheless, we have significantly expanded the number of consumer products with bottles made of 100% recycled plastics.”

-Circular in Motion targets recycled-content plastics

European online platform seeks to provide marketplace for companies with recycled-content sustainability goals.

Netherlands-based Circular in Motion says it is starting with plastics as it introduces its online platform “to sell and buy sustainable materials” in an effort to “help operators, from municipalities to companies of all sizes, shift from linear to circular economy.”

“In Europe, we have a big gap between offer and demand of the secondary raw materials, and we need to bridge this,” says Leila Oksanen, chief commercial officer of Circular in Motion. “We want to help companies connect, generate business and create value chains around sustainability. We are certain the accessible e-marketplace can be a concrete boost to the European circular economy, and of course beyond EU borders too.”

Continues Oksanen, “We help match the supply and demand of the recycled and renewable content raw materials and make it possible for all kinds of operators, big and small, to be part of circular economy.”

-Volume Resin Prices Keep Rising

Constrained supplies, higher feedstock costs, and continued strong demand fuel ongoing price hikes.

Going into 2021, prices of the five volume commodity resins seem set to continue their upward march, at least for now. Driving this trajectory were higher feedstock costs, supplies tightened by production outages, and healthy domestic and export demand for all of these resins but polystyrene. In some cases, most notably polypropylene, suppliers aimed to push through non-feedstock-related price increases to boost their profit margins.

Those are the views of purchasing consultants from Resin Technology, Inc. (RTi), senior editors from PetroChemWire (PCW) and CEO Michael Greenberg of The Plastics Exchange.

Petrochemical AutomotiveIndustries R-PET