Petrochemical Biochemicals Antibacterial 02-01-2021 - Arhive

Petrochemical Biochemicals Antibacterial

-MY SHAPES, antivirus textiles from an Italian patent

A line of garments capable of inactivating viruses and bacteria present on the surface of fabrics. This is the one proposed by the company GEA srl of Modena with MY SHAPES Stay Safe: a collection that uses an antiviral yarn born from the Rhodia / Solvay laboratories and produced under license in Italy by FULGAR Spa.

An extra barrier against viruses and bacteria

The ingredient used for the products of the MY SHAPES Stay Safe line is the Q-SKIN® yarn powered by AMNI® Virus-Bac OFF, a very recent patent containing an antiviral and antibacterial agent in its polymeric matrix capable of deactivating in particularly short times the pathogens that come into contact with the worn garment; all with a verified effectiveness following the international textile protocols contained in ISO 18184 and the international textile standards AATCC100.

The new technology – the company explains – inhibits enveloped and non-enveloped viruses (influenza, herpes and the new Coronavirus), helping to avoid the retransmission of the viruses from textile surfaces. No chemical migration occurs from the fabric to the skin and the environment. The yarn blocks the cross-contamination of viruses and bacteria on textile surfaces, inhibits bacteria, ensuring greater protection and has a stable and unlimited efficacy over time.

-Plastics Recycling with Tracer-Based-Sorting: Challenges of a Potential Radical Technology

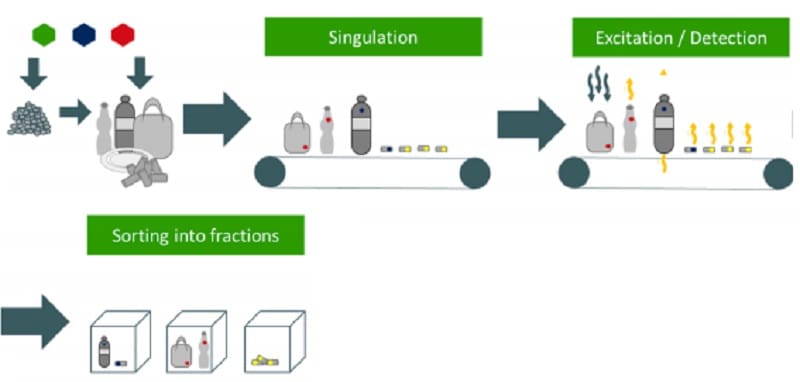

Abstract: To improve the recycling quality of plastics packaging and achieve high recycling rates new identification and sorting technologies are required. Tracer-based-sorting (TBS) is an innovative

identification technology based on fluorescent tracers and a corresponding detection unit. TBS can be considered a radical technology change towards a circular economy for plastics and to support

sustainability as it has the potential to render several established sorting and/or recycling steps obsolete. This article shows which drivers and barriers are perceived by stakeholders with regard to

the implementation of TBS in the market and how challenges are addressed responsibly in the early phases of the innovation process. Influencing external factors and framework conditions of TBS are

identified and suitable business models for TBS in a circular economy are discussed. Further, practical recommendations on how to optimize technology and market development for TBS are provided. To

obtain these results a mixed method approach of integrated innovation and sustainability analysis, external environment analysis (PESTEL analysis), and business model development approaches was

chosen. The research results can be understood as a practical contribution towards a responsible and sustainable implementation of a radical technology-based innovation for a circular economy of plastics.

-Key elements of the EU-China Comprehensive Agreement on Investment

The cumulative EU foreign direct investment (FDI) flows from the EU to China over the last 20 years have reached more than €140 billion.

For Chinese FDI into the EU the figure is almost €120 billion. EU FDI in China remains relatively modest with respect to the size and the potential of the Chinese economy.

As regards investment, the EU-China Comprehensive Agreement on Investment (CAI) will be the most ambitious agreement that China has ever concluded with a third country.

In addition to rules against the forced transfer of technologies, CAI will also be the first agreement to deliver on obligations for the behavior of state-owned enterprises, comprehensive transparency rules for subsidies and commitments related to sustainable development.

-ALL THAT GLITTERS: ECO-FRIENDLY OPTIONS STILL SPARKLE

As if 2020 hasn’t handed us enough heavy blows, along comes a pill that will be especially hard for Key Westers to swallow. Friends, this won’t be easy, but we have to talk about … glitter. Sadly, the world is realizing that our sparkletastic standby is classified as a microplastic.

Microplastics are exactly what they sound like — minuscule bits of plastic that find their way into the soil and water, wreaking particular havoc on oceans and aquatic life. This form of pollutant is divided into two categories: plastic products such as bottles that eventually break down to sand-sized particles, and microplastics that are initially produced as tiny units of waste. The latter has typically been defined as microbeads, those teeny little globs found in scrubs and soaps. In 2018, microbeads in cosmetics were banned in the U.S. and Canada, drastically diminishing this particular subset of waste. Other countries followed suit, giving credence to the concept that these little specks were inarguably detrimental to the environment.

What wasn’t initially considered was the microbead’s fabulous, flashy and flamboyant cousin, glitter. As much as we wish it didn’t, logic follows that if microbeads and microplastics in general have a profound negative effect on the oceans, so does glitter.

-The battle over biodegradable plastics

A British company promotes its vision for plastics that break down into harmless substances.

There’s a spat between tech companies trying to develop a new generation of plastics that biodegrade harmlessly without leaving a trace and skeptics worried that such novel substances won’t live up to their promise and will worsen the plastic waste problem.

The companies are calling for more time to perfect their inventions — which they say differ from earlier efforts to make cleaner plastics — while environmental campaigners demand even firmer regulatory action to get rid of plastic garbage. Firms are also battling against the image problem of an earlier generation of innovative biodegradable plastics that experts say haven’t lived up to the hype.

“The popular understanding of biodegradability is based on legacy solutions such as oxodegradable plastic, many of which unfortunately don’t work,” said Niall Dunne, the CEO of British firm Polymateria, adding that the “landscape has moved on significantly yet outdated perceptions remain.”

-PROCESS FOR RECYCLING OF COTTON GARMENTS PRODUCES MULTI-TON QUANTITIES FOR TESTING

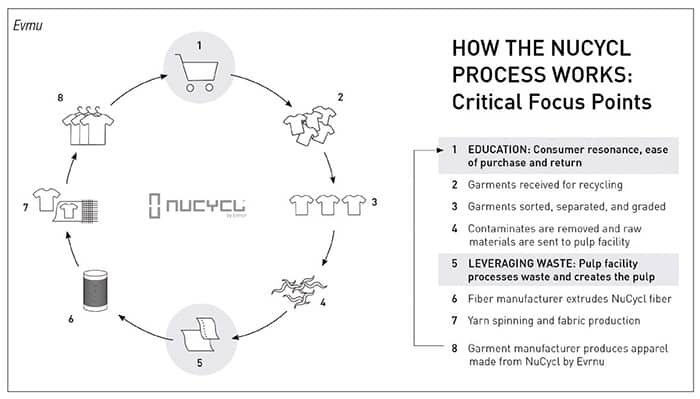

A process developed by Evrnu (Seattle, Wash.; www.evrnu.com) to regenerate cotton fibers from waste fabric and post-consumer garments has been used to produce ton quantities of recycled cotton fiber for testing.

An economically viable process for recycling cotton would have the environmental benefits of drastically reducing the amount of landfilled or incinerated fabric, which currently totals millions of tons annually, while also reducing the amount of land and water required to grow the cotton plants.

Evrnu has developed an end-to-end process, known as NuCycl, that includes sorting fabrics to identify the types of fibers in the textile, shredding the textiles and removing the dyes and additives (diagram).

-Americans are not causing the ocean plastic problem

For years, environmental activists and political leaders have used images of waste-filled beaches to turn consumers against plastic. The imagery has been used to support calls to ban common single-use plastics, including straws, shopping bags, bottled water, and more. Thinking they are helping the environment, many Americans support these policies.

But is plastic trash in the United States actually as bad as we’ve been led to believe? New evidence provides important context.

A study published this fall in Science Advances generated breathless headlines claiming that the U.S. is a major culprit for plastic in the ocean. A dive into the study itself shows the opposite.

PepsiCo, producer of soda beverages and snack brands such as Lay’s potato chips, among other products, joined forces with Danimer Scientific several years ago with the goal to develop sustainable flexible packaging, Danimer says in a news release published on its website.

According to the release, Danimer Scientific developed biobased compostable packaging for PepsiCo’s snack brands in the past. The new initiative is said to be “right in line with PepsiCo’s announced strategy to make all of its packaging recoverable or recyclable.”

PepsiCo Vice Chairman and Chief Scientific Officer Dr. Mehmood Khan is quoted as saying “our plan to scale Danimer Scientific’s technology is a step toward achieving both our greenhouse-gas emission reduction and our recoverable and recyclable packaging goals.”

The BCG model encompasses industries that allow inclusive, sustainable growth while reducing waste, pollution, and dependence on finite resources

In the first nine months of 2020, local and international companies applied to invest as much as $1.7 billion in Thailand in more than 300 projects in the sectors listed as “BCG”, or Bio-Circular-Green economic activities focused on environmental protection and sustainability, according to data collected by the Thailand Board of Investment (BOI). An announcement was made on 24 Dec 2020.

This lifted the total value of BCG applications since the start of 2018 to $6.7 billion, reinforcing Thailand’s position as a Bio-Circular-Green hotspot, the BOI said.

The BCG model, as defined by the Thai Government, encompasses industries that allow inclusive, sustainable growth while reducing waste, pollution and dependence on finite resources. Thailand is a major agricultural producer, tourism destination and medical hub and its BCG sector comprises many of the country’s important industries: agriculture and food; bioenergy, biomaterials and biochemicals; medical and wellness; and tourism and the creative economy.

-Saudi AGIC signs offtake agreements for new PP project

Saudi petrochemical producer Advanced Petrochemical has signed through its subsidiary Advanced Global Investment (AGIC) offtake sales agreements of polypropylene with traders Vinmar, Tricon and Mitsubishi. These will last until 31 December 2028, with volumes to be delivered from its planned Advanced Polyolefins (APOC) plant in Jubail, Saudi Arabia.

The PP offtake agreements total 620,000 t/yr, with Vinmar and Tricon procuring 250,000 t/yr each, while Mitsubishi will take 120,000 t/yr. The agreement will take effect on the date of commercial operations commencing at APOC, which is targeted for the second half of 2024. No details were known on the underlying pricing basis of the offtake agreements.

Petrochemical Biochemicals Antibacterial