Petrochemical BOPPFilm Hydrogen 29-12-2020 - Arhive

Petrochemical BOPPFilm Hydrogen

Crude Oil Prices Trend

-PFY downstream market not slack during off-season

Sales and orders of downstream plants hit expectation during this period. Local sales improved, mainly driven by the replenishment of traders for the production during Lunar New Year holiday.

Orders for fabrics for winter wear were moderate and those for summer wear and spring wear were placed successively.

Orders for fabrics for home textiles were relatively better than other varieties.

Some large plants in Changxing even did not plan to shut down for holiday. Domestic business of circular knitting plants improved in Shaoxing, especially large companies. Downstream plants may put their holiday schedule for the Spring Festival ahead this year due to the pandemic, which are one of the reasons for better downstream orders as some traders replenish in advance.

Some water-jet mills and circular knitting plants that saw poor business may put their holiday schedule for the Lunar Chinese New Year, and most twisting units and fabric mills are unlikely to start holiday in advance. Firstly, downstream market performed moderately now and feedstock price was low.

-A.P. Moller Holding invests millions in Green Hydrogen Systems

Denmark’s A.P. Moller Holding, a parent company of shipping major Maersk, has decided to invest in compatriot Green Hydrogen Systems, a supplier of modular electrolyzers producing green hydrogen from renewable energy.

As informed, A.P. Moller Holding will invest in Green Hydrogen Systems in the form of a convertible loan of EUR 20 million (around $24 million).

“We see hydrogen as an important part of the future green energy mix for industry, shipping and heavy transport,” Jan T. Nielsen, CIO, A. P. Moller Holding, commented.

“Green Hydrogen Systems has a compelling technology platform for electrolytic hydrogen production based on green energy and we are excited to support them in developing this platform further.” Petrochemical BOPPFilm Hydrogen

-Grooming nylon 6 market, beware of risk from the commodities

In December, nylon 6 industrial chain has been driven by caprolactam market, and the specific reasons have been sorted out in the previous insight “Caprolactam still bullish in December despite changing logics”.

It is mainly based on the considerable sales/production of nylon 6 chip industry as a whole, fermented with tightening CPL supply and bullish benzene performance. The basic logic in the uptrend in December is a continuation of that in November, and no other factors are noticed in the month. Petrochemical BOPPFilm Hydrogen

In the past half month, Haili, Juhua, and Lanhua have stopped production one after another, and the fundamentals of benzene remains healthy.

The external environment is relatively mild: oil prices fluctuate up slowly, and the economic data released in November continues to improve steadily. No alerting news to the market appear over the past month.

-INTESA SANPAOLO AND NOVAMONT: 20-MILLION-EURO

CIRCULAR LOAN AGREEMENT

FOR TWO INNOVATIVE PROJECTS

- The world’s first plant for generating a new monomer to produce biomaterials from renewable sources will be completed in Terni.

- Bottrighe (Rovigo) will be the most efficient facility in Europe for the production of chemical intermediates from renewable sources, thanks to the construction of a high-quality biogas plant.Petrochemical BOPEFilm Hydrogen

- Catia Bastioli: ” The project we launched 30 years ago has become a genuine showcase for Italy, feeding several high- value supply chains throughout the country using a systemic, transformative and multidisciplinary approach to redesign. The two projects at our production sites in Terni and Bottrighe represent yet another step in this direction.” Petrochemical BOPPFilm Hydrogen

- Mauro Micillo: ” To support initiatives like these and the gradual transition towards the circular economy, in the 2018- 2021 Business Plan, the Intesa Sanpaolo Group made a 6- billion-euro Circular Economy Fund available to businesses. To date, a total of 1.5 billion euro have been used to finance many initiatives in Italy and abroad.”

-EU BANS PLASTIC WASTE FROM BEING SHIPPED TO DEVELOPING COUNTRIES

The European Union has banned all non-recyclable plastic waste being shipped to developing nations from 1 January. Petrochemical BOPPFilm Hydrogen

The large quantity of plastic sent to the Global South is often not being properly treated. A lot of this waste ends up either in landfill, the ocean, or being incinerated because these countries often don’t have the capacity to sustainably treat the waste.

Under the new rules, only ‘clean plastic waste’ which can be recycled is allowed to be exported to non-OECD (Organisation for Economic Co-operation and Development) countries. In addition, stricter measures have been adopted on the export of plastic waste from the EU to OECD countries and intra-EU shipments of plastic waste.

EUROPE’S WAR ON PLASTIC

Every year, Europeans generate 25 million tonnes of plastic waste, but less than a third (30 per cent) of it is being recycled. And across the world, plastics make up around 85 per cent of beach litter.

On 17 December, BASF opened its ASEAN Technical Development Center adjacent to its existing polyurethane (PU) System House at Bangpoo site in Thailand, as per the company’s press release. Petrochemical BOPPFilm Hydrogen

The new facility houses a state-of-the-art pre-polymer reactor technology to produce a hardener (component B) – a key component to boost product development efficiency, thereby enabling faster time-to-market of PU materials and solutions.

The advanced reactor technology is further designed to deliver on a much larger capacity, meeting most demanding customer requirements across all grades. The new pre-polymer reactor technology is additionally capable of developing customized PU System products, which helps improve the commercialization of these specialized solutions.

The ASEAN Technical Development Center also boasts several new service upgrades, such as more advanced testing and software capabilities. With the new pre-polymer reactor technology, the ASEAN Technical Center strengthens and complements BASF’s technical support network in China, Korea, and Germany.

-Highsun invests in new nylon-6 line in China

HSCC, also known as Highsun, is installing a polyamide 6 (PA6) film grade polymer line with a nameplate capacity of more than 70,000 tonnes/year at its site in Fuzhou, Fujian province, said Chemweek.

The line will include an integrated dry-blending system, enabling HSCC to produce a full range of differentiated PA6 polymers targeted at the film market, it said in a statement.

70,000-metric tons/year PA6 production line in Fuzhou will start operations in March 2021.

German chemical engineer Uhde Inventa-Fischer is the project’s technology partner. Financial details were not disclosed. Petrochemical BOPPFilm Hydrogen

As it was written earlier, in accordance with the agreement initially announced on June 10, 2019, Air Liquide has closed the sale of its subsidiary Air Liquide Fuzhou to Highsun Holding Group, the parent company of Fujian Shenyuan New Materials Co., Ltd.

-Avient Colorforward™ experts predict pandemic likely to influence color preferences, even in 2022

December 28, 2020 | Material technology | Avient Corporation | Milan | Italy

Avient Corporation, a premier provider of specialized and sustainable material solutions and services, today announced that Avient ColorWorks™ has launched ColorForward™ 2022. This 16th edition of the annual color forecasting guide for the plastics industry marks its debut within Avient, which was formed this year from legacy businesses PolyOne and Clariant Masterbatch.Petrochemical BOPPFilm Hydrogen

As in years past, ColorForward 2022 presents stories associated with four societal trends that are expected to influence consumers consciously or unconsciously over the next few years. Each trend theme also includes a palette of five associated colors that are predicted to elicit a response from consumers. Developed by a global team, many of whom work in the four Avient ColorWorks™ design and technology centers around the world, this unique tool has become invaluable to plastic product designers and marketing professionals seeking help in making more informed color choices for new products and packaging.

-Online Exclusive: Ushering in a new era of sustainable plastics

Research suggests the amount of plastic waste entering the world’s oceans could almost triple to 29 MMtpy by 2040[1]. It is a bleak prediction that highlights the scale of the challenge, which must be addressed not only by governments and consumers, but also by plastics manufacturers themselves. The solution may lie in the next-generation of degradable plastics.Petrochemical BOPPFilm Hydrogen

As we discovered through the coronavirus pandemic, the problem with trying to phase out plastics – even the single-use variety – is that there is often nothing else to replace them with (as of yet). That is why, rather than focusing on plastics consumption, we should instead be directing resources towards finding sustainable solutions that address the issue of plastic waste at source.

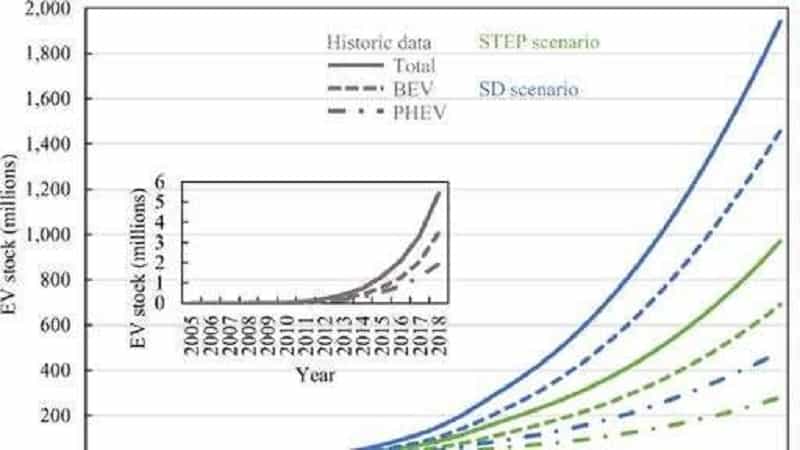

-Future material demand for automotive lithium-based batteries

As the world shifts to electric vehicles to reduce climate change, it is important to quantify future demands for key battery materials. In a new report, Chengjian Xu, Bernhard Steubing and a research team at the Leiden University, Netherlands and the Argonne National Laboratory in the U.S. showed how the demands of a lithium, nickel, cobalt and manganese oxide dominated battery will increase by many factors between 2020 to 2050. As a result, supply chains for lithium, cobalt and nickel will require significant expansion and likely additional resource discovery.Petrochemical BOPEFilm CrudeOil

Nevertheless, uncertainties are large relative to the development of electrical vehicle fleets and battery capacities per vehicle.Petrochemical BOPEFilm Hydrogen

While closed-loop recycling plays a minor but increasingly important role to reduce the primary material demand until 2050, researchers must implement advanced recycling strategies to economically recover battery-grade materials from end-of-life batteries. This work is now published on Nature Communications Materials.Petrochemical BOPPFilm Hydrogen

Petrochemical BOPPFilm Hydrogen