Petrochemical Hydrogen Bioplastics 30-10-2020 - Arhive

Petrochemical Hydrogen Bioplastics

Crude Oil Prices Trend

-LG Chem Develops World’s First Biodegradable New Material

Expected to be used broadly in areas such as eco-friendly packaging materials, mask felt, etc.

Transparent biodegradable new material with mechanical properties equivalent to PP(polypropylene), etc.

Improved flexibility by more than 20 times compared to existing biodegradable materials

Biodegradable materials market is expected to grow at an annual average of 15% and be worth about 10 trillion KRW in 2025

Successfully developed new materials with proprietary platform technologies for core biodegradable materials

– Possesses a total of 25 domestic and international patents

– Confirmed results of over 90% biodegradation within 120 days through an international certification agency

-Rayon yarn: demand warms up but profit not easy

In “crazy” October, after VSF rose by 5,000yuan/mt at the end of September, it then picked up further by 1,500yuan/mt. PSF increased by about 1,000yuan/mt and cotton rose by 2,000yuan/mt from that in early this year. In the first half of the month, strong trading sentiment shrouded in the market, while it rapidly cooled down in the second half. Cotton and polyester also fell by 500-1,000yuan/mt, and viscose was also affected but relatively kept strong.Petrochemical Hydrogen Bioplastics

It has been mentioned many times before that VSF experiences a longer period of price volatility without futures. Despite the recent slowdown in fresh orders, under the support of a large number of pre-sales, if VSF plants intended to quote firmly, orders can maintain production through end-2020. Instead, there will be fewer high-priced deals.

The bounce of the market was inseparable from the change of supply and demand. On the one hand, VSF operating rate cannot rapidly increase due to the limitation of feedstock and other factors. On the other hand, as downstream yarn operating rate recovered basically and optimistic mood spread in intermediate links, the whole market gradually crawled out of the shadow of relative surplus and deep loss.

-Film Processor Boosts Line Performance with Air-Ring Retrofit

Air-ring upgrade results in output gains up to 23% for leading film processor in Indonesia. Gauge uniformity also improved.

One of Indonesia’s leading processors of high-end flexible packaging films has experiencing significant gains in productivity as a result of upgrading lines with new air rings furnished by Windmoeller & Hoelscher (W&H). Petrochemical Hydrogen Bioplastics

Based in Jakarta, PT Plasindo Lestari was founded in 1986, and currently employs more than 1400 from a 1-million-ft2 plant, making films for food, beverage, home-care and personal-care packaging. The company’s product portfolio includes LLDPE-based barrier films, cast PP and metalized PP and PE in a range of thicknesses. Its operation is integrated to include printing in up to eight colors and inline dry lamination. The company serves both local and multinational brands.

-Dow Launches its First Recycled Resin for Shrink Film Applications

The recycled plastic resin is designed specifically for retail and logistic shrink film applications.

Dow is expanding its circular technology portfolio by introducing its first post-consumer recycled (PCR) resin for collation shrink film in North America.

The recycled plastic resin, which is designed specifically for retail and logistic shrink film applications, offers customers and brands the ability to create shrink film with up to 40% PCR content. In June 2020, Dow announced new sustainability targets focused on eliminating plastic waste by increasing global recycling and designing products for recyclability. Petrochemical Hydrogen Bioplastics

Earlier this year, Dow announced a partnership with Houston-based waste-optimization specialist Avangard Innovative on producing Dow’s first post-consumer resin PCR-based products in North America.

-Additives: Special Stabilizer Boosts Rate of Scrap Reused in Polyolefin Films

Clariant’s latest addition to the AddWorks family of stabilizers allows for the addition of more post-manufacturing waste to virgin polyolefin resins for food-contact film applications. Petrochemical Hydrogen Bioplastics

A special stabilizer intended for use with polyolefin film packaging of such fresh products as cookies and pasta is said to substantially boost the rate of scrap reused in the polyolefin film. Developed by Clariant’s Business Unit Additives (U.S. office in Charlotte, N.C.), PKG 906 Circle is the latest addition to the company’s proprietary AddWorks additives.

The company notes that most plastic films are made by melting down pellets of PE or PP resin and casting or blowing them into large sheets and tubes, or using a special process to make biaxially oriented PP or PE (BOPP and BOPE, respectively). But some of the machines used, which actually resemble huge pasta rollers, collect manufacturing waste when films are slit and trimmed, or when production startups, shutdowns and changeovers create leftovers and off-spec material.

-WRAP clarifies stance on degradable plastics PAS

The Waste & Resources Action Programme (WRAP) says its presence on the steering committee of a new specification (PAS) for measuring the biodegradability of polyolefins should not be taken as an endorsement of the standard.

The British Standards Institution (BSI) specification, PAS9017, was sponsored by a company which produces biodegradable and compostable plastics and was published earlier this month. Petrochemical Hydrogen Bioplastics

Last week, more than 40 organisations called for a ban on plastics containing additives to make them degrade in response to the standard’s publication (see letsrecycle.com story).

Padanaplast specialises in cross-linkable, polyolefin, halogen-free, flame-retardant (XLPO-HFFR) compounds for wires and cables and offers a range of products developed to meet the stringent needs of electric mobility in the automotive industry.

Antonello Casale R&I & Technical Service Chief Manager at Padanaplast, said: “The surging development of complex hybrid, all-electric and fuel cell vehicles demand advanced automotive wires and cables to meet a range of voltages and performance criteria.

We are complementing our successful range of HFFR insulation and sheathing for wire and cabling for e-mobility with the introduction of experimental T4 150°C grade of Cogegum GFR.” Petrochemical Hydrogen Bioplastics

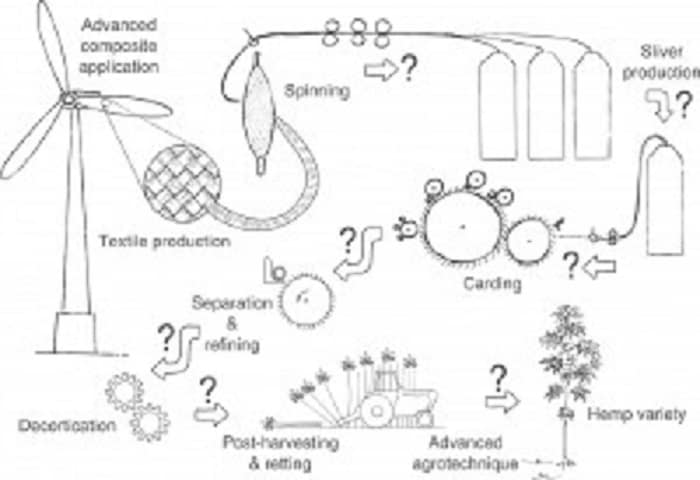

-Hemp in high-performance composites?

What potential do hemp fibres have to be used in fibre-reinforced composites – researchers of the Biomimetic Innovation Centre at HSB publish a comprehensive review with colleagues from France, Italy and England Petrochemical Hydrogen Bioplastics

In recent years, the increasing demand for renewable and sustainable materials has generated a new interest in plant fibres. The growing importance of sustainable – social, ecological and economic – development of materials and products also contributes to the growing importance of composites made of natural fibres. Significant research and development work has been carried out and implemented in the field of natural fibre-reinforced composites. In the field of natural fibre-reinforced composites, various processing techniques for the production of a wide range of materials are available or under development. The applications range from injection moulded toys for children to high-performance composites in the sports sector or in yacht construction.

-Idealpak’s new biodegradable packaging with d2w

D2w is an oxo-biodegradable additive that can turn the conventional plastic into a biodegradable material Petrochemical Hydrogen Bioplastics

D2w is an oxo-biodegradable additive that can turn the conventional plastic into a biodegradable material with a different molecular structure. Only 1% of d2w can make the difference and it works with both virgin and recycled plastic. Adding d2w into a packaging product requires no change to the manufacturing process.

D2w technology can be applied to HDPE bottles and jars, LDPE bottles and jars, HDPE closures, LDPE closures, PP bottles and jars, as well as PP closures.

-Auxiliary Equipment: The most efficient way to process regrind

Plastics producers are always looking for the most sustainable and cost-effective way to produce their products. Petrochemical Hydrogen Bioplastics

We also notice this in the growing demand for regrind systems from the market.

Having regrind in your process can be very time consuming when it comes to emptying and cleaning inbetween two production runs.

Also it disturbs your production process when it is not added in the right way.

You can make it easy on yourself by using the right equipment.

Auxiliary equipment maker Movacolor has dedicated dosing systems for specific regrind applications.

-Lotte Chemical works with college medical center to develop anti-bacterial plastic materials

Lotte Chemical, a petrochemical unit of Lotte Group, will work with a college medical center to develop anti-bacterial plastic materials. Antibacterial films and materials are widely used in South Korea for elevator cabins, door handles and other vulnerable places to prevent the invasion of viruses. Petrochemical Hydrogen Bioplastics

Lotte Chemical signed a memorandum of understanding with the Korea University Medical Center to jointly research and develop plastic materials of antibacterial properties and evaluate their performance.

Although various anti-bacterial materials are used, there is a lack of research on safe plastic materials, Lotte Chemical said, vowing to develop new plastic materials that have a wide range of antibacterial performance through joint research.

Petrochemical Hydrogen Bioplastics

Petrochemical Hydrogen LLDPE Automotive 29-10-2020