Petrochemical Nylon Film Automotive 23-10-2020 - Arhive

Petrochemical Nylon Film Automotive

Crude Oil Prices Trend

-Styrolution receives funding for new styrenics recycling research

Styrolution has received Belgian government funding for new research into the potential recycling of styrenics using dissolution technology.

The styrenics subsidiary of Ineos says it will be contributing to the ‘Remove2Reclaim’ project, which is researching the recycling of plastics and titanium dioxide using advanced dissolution and separation techniques for plastic additive removal. No financial details were given.

The project involves several leading research institutes in Belgium, with the aim of developing solvent-based extraction routes to remove additives such as titanium dioxide from different polymer matrices.

-Saya introduces recycled scrap at TITAS

Saya, a new name in recycled fibre, made its live debut at Taipei Innovative Textile Application Show (TITAS). The show showcased sustainable textiles which reduce resource usage and optimise manufacturing efficiency through eco-friendly materials and processes. Saya’s Rscuw, fibres made of recycled cutting scrap & overstock yardage, was featured at TITAS. Petrochemical Nylon Film Automotive

The brand’s film (Saya Rscuw launch video), depicted the motivation behind finding new sources of materials to be recycled and the process developed by Saya engineers.

“We have the experience, knowledge and equipment to make change,” said SY Huang, senior vice president of Nan Ya Plastics, Saya’s parent company, and the world’s largest manufacturer of recycled PET repurposing over 75 billion bottles every year. “Under the new brand, Saya, we’ve been able to put our resources toward solving one of the most critical sustainability issues in the textile industry – recycling discarded fabric scrap and unused yardage. We want to take responsibility and redefine what’s possible in renewal.”

-Recycling barely dents crude demand as global infrastructure remains poor – IEA

Crude oil demand from petrochemicals will rise in coming years as virgin plastics continue to be churned out at pace given the poor implementation of recycling infrastructure across the globe, a petrochemicals analyst at the International Energy Agency (IEA) said.

Tae-Yoon Kim said that for recycling to be a competing factor against virgin plastics the infrastructure across the world – apart from some in EU countries – would have to be Petrochemicdeveloped quickly, something that is not happening.al Nylon Film Automotive

The analyst said countries should put at the centre of recovery packages post-pandemic green policies like recycling; however, so far only the EU’s Green Deal has made that a priority; he mentioned the Green Deal as an example to follow.

-Breaking the myth between PVC and PET-G

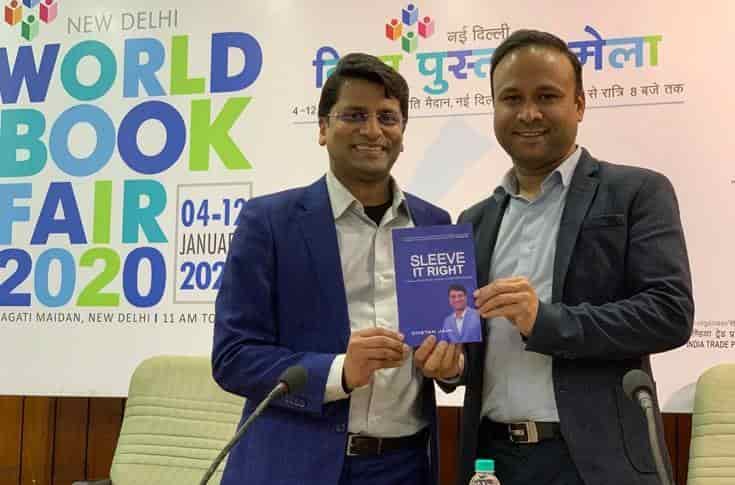

Chetan Jain, executive director, Taurus Packaging, who recently published a book titled ‘Sleeve It Right: 7 Secrets of Shrink Sleeves not known to India’s FMCG Businesses’, debunks the myths surrounding PVC shrink films.

PVC shrink films have ruled the Indian packaging industry for the longest time. However, due to issues associated with PVC, a need was felt to find an alternative material that could potentially replace PVC. Several different polymers were introduced and tested in the market but saw little success. Finally, PET-G was born. With this, the packaging industry had found the best shrink sleeve yet. Petrochemical Nylon Film Automotive

However, questions remained. Is it practical and even possible to replace PVC altogether? Is PVC truly all bad and PET-G all good? Can PET-G shrink films offer the same quality and finish as PVC shrink films? Do companies have the resources, knowhow and infrastructure to use PET-G packaging material for all types, shapes and sizes of containers?

-Nova Chemicals to sell expandable styrenics business to Alpek

Nova Chemicals (Calgary, Alberta, Canada) has agreed to sell its expandable styrenics business to a subsidiary of Alpek (Monterrey, Mexico) for an undisclosed sum. The transaction is expected to close in the fourth quarter, it says.

The sale encompasses Nova’s expandable polystyrene (EPS) and Arcel-brand resin product lines, with manufacturing facilities in Monaca, Pennsylvania, and Painesville, Ohio, as well as commercial operations in Asia, it says. The plant at Monaca has an EPS production capacity of 123,000 metric tons/year, with 36,000 metric tons/year of capacity for Arcel, as well as an R&D pilot plant. The facility at Painesville has an EPS capacity of 45,000 metric tons/year, according to Alpek subsidiary Styropek, which is acquiring Nova’s business.Petrochemical Nylon Film Automotive

Nova, a wholly owned subsidiary of Mubadala Investment Co. (Abu Dhabi, UAE), says the sale is an “important step” in its plan to focus on its olefin and polyethylene (PE) business, which includes additional investments to advance a circular economy for plastics. The transaction, if it proceeds to completion, would see Nova entirely exit the styrenics sector.

-AmSty Commits to 25% Recycled Polystyrene by 2030

With an end goal of keeping polystyrene products out of landfills through an innovative circular recycling process, AmSty is announcing its commitment that all products designed for foodservice and food packaging applications will contain 25 percent recycled content by 2030. The leading integrated producer of polystyrene and styrene monomer continues to reach milestones toward this goal with its circular recycling process operating commercially at Regenyx LLC, its joint venture with Agilyx Corporation.

Regenyx is achieving this circular recycling breakthrough using technology that breaks down polystyrene products to their original molecular form. The resulting styrene monomer is then used to create the exact same products again, with original quality and function. Since start-up, Regenyx has converted more than one million pounds of used polystyrene to all-new materials. That’s equivalent to keeping 37.5 million foam cups or 32.5 million takeout containers out of the landfill.Petrochemical Nylon Film Automotive

-Saudi Arabia’s business community pressured ‘to not buy made in Turkey’

A Saudi woman looks at the dairy products in a supermarket in Riyadh, Saudi Arabia, Oct. 18, 2020. (Reuters Photo)

A Saudi woman looks at the dairy products in a supermarket in Riyadh, Saudi Arabia, Oct. 18, 2020. (Reuters Photo) Petrochemical Nylon Film Automotive

As political tensions between Ankara and Riyadh spill on trade, Turkish exporters have voiced concerns that they have been experiencing growing difficulties with Saudi Arabia.

“It has been going on for a year, but in the recent period, the pressure on businessmen in Saudi Arabia ‘to not buy made in Turkey’ has come up,” said Ferdi Erdoğan, head of the Association of Turkish Construction Material Producers (IMSAD).

Erdoğan’s remarks came as Saudi Arabia’s biggest supermarket chains this week joined a growing “boycott” of Turkish imports proposed by business leaders and Saudis on social media.

-Scrap tire recycling markets not keeping pace with generation, report shows

A U.S. Tire Manufacturers Association report reveals that almost 76 percent of scrap tires were recycled in products such as rubber-modified asphalt, automotive products, mulch for landscaping, and tire-derived fuel in 2019. This is down from 96 percent in 2013, when scrap tire recycling peaked.Petrochemical Nylon Film Automotive

The U.S. Tire Manufacturers Association (USTMA) released its 2019 Scrap Tire Management Report on Oct. 14. According to the report, while tires remain one of the most recycled products in the U.S., end-of-life markets are not keeping pace with the annual generation of scrap tires.

The report reveals that almost 76 percent of scrap tires were recycled in products such as rubber-modified asphalt, automotive products, mulch for landscaping, and tire-derived fuel in 2019. This is down from 96 percent in 2013, when scrap tire recycling peaked.

-CSP’s Portugal-based operations, Inapal Plásticos, reduces weight for new SUV

Inapal Plásticos, Continental Structural Plastics’ (CSP) operations in Portugal, will be manufacturing a number of lightweight, low-density sheet moulded compound (SMC) components for a premium luxury automotive company’s first SUV.

These 11 components, ranging from underhood to underbody and Class A components, will reduce part complexity and overall vehicle weight. Petrochemical Nylon Film Automotive

By moulding the complex radiator assembly frame in a low-density composite material, the OEM was able to minimise the number of parts required under the hood, significantly reducing assembly complexity and weight. Such parts are traditionally steel or aluminium and require multiple stamped components to be assembled to create the final product.

-Bioplastics will need significant government intervention to realize full potential, report says

In order to achieve the scale needed to play a meaningful role, the report from Wood Mackenzie says, the bioplastics industry will require significant regulatory interventions from governments and substantial cost efficiencies as technologies mature and scale.

Based on the fundamentals of their environmental footprint compared to that of virgin fossil fuel-derived plastics, biodegradable bioplastics could significantly reduce the carbon emissions of the chemicals industry, a new report from energy consultancy group Wood Mackenzie says – but in order to achieve the scale needed to play a meaningful role, the bioplastics industry will require significant regulatory interventions from governments and substantial cost efficiencies as technologies mature and scale. Petrochemical Nylon Film Automotive

Petrochemical Nylon Film Automotive