Petrochemical PET Recycling Packaging 06-11-2020 - Arhive

Petrochemical PET Recycling Packaging

Crude Oil Prices Trend

-Husky launches NexPET™ – New System Offering Infinite Possibilities

Flexible mid-volume system purpose-built to quickly and easily produce just the right output for multiple preform designs

Husky Injection Molding Systems, a leading technology provider to the plastics processing community, has launched its new NexPET™ system – a game-changing mid-volume PET preform molding solution purpose-built to help producers introduce multiple new applications into the market more quickly and cost-effectively than ever before.

Built upon Husky’s industry-leading technology, the NexPET™ system is engineered to enable both established and emerging producers be more competitive by better responding to evolving consumer preferences – while achieving the highest levels of value, flexibility, reliability and sustainability. For established producers, NexPET™ delivers an agile, reliable solution to accommodate niche brands or smaller run SKUs. For emerging producers, it is a proven, cost-effective solution that enables fast, low-risk entry into markets.

LyondellBasell, REHAU, and Eschmann Textures have announced the successful creation of a physically foamed rear lower trim with an excellent surface appearance.

With growing concerns about climate change and environmental degradation, sustainability has become a strategic priority for automotive manufacturers. When the BMW Group was looking for a bumper design for a new car model, which had to meet the companies’ sustainability goals, engineers from LyondellBasell, REHAU and Eschmann Textures took up the challenge. Petrochemical PET Recycling Packaging

The partners opted for a foamed part to achieve the necessary weight reduction. Due to the combination of the expertise, the foamed part achieved the highest surface/quality ranking and passed a certificated test series with good results.

-BGN Technologies and ECOIBÉRIA collaborate for Biodegradation of Plastic

BGN Technologies, the technology transfer company of Ben-Gurion University of the Negev (BGU), announced today that it had signed a research collaboration agreement with ECOIBÉRIA in the field of plastic recycling by bacteria, based on research from the team of Prof. Ariel Kushmaro and Prof. Alex Sivan, both from the Laboratory of Environmental Biotechnology and Avram and Stella Goldstein-Goren Department of Biotechnology Engineering at BGU. Petrochemical PET Recycling Packaging

Polyethylene terephthalate (PET) is the most abundantly used polymer in the world, with multiple applications in the textile industry as well as in food and beverage packaging. It is estimated that about 56 million tons of PET are produced yearly worldwide, mostly as single use packaging material. Therefore, intense efforts are directed towards recycling and reuse of the PET plastic materials.

-Look but don’t touch: The SICK SPEETEC speed and length sensor

With the SPEETEC non-contact sensor for speed and length measurement, SICK has added a compact, affordable, eye-safe laser surface motion sensor to its portfolio, able to measure a wide range of continuous, web-fed or cut-to-length plastic products down to a resolution of 4µm. Petrochemical PET Recycling Packaging

The SPEETEC combines unprecedented affordability with precision surface measurement for process control and quality inspection tasks used in the manufacture of plastic products, including processes such as extrusion of plastic pipes or UPVC profiles, and cut to length of sheet materials. The Class 1 eye-safe infra-red laser light eliminates the need for special guarding or safety measures required by many conventional velocimeters.

-Mitsubishi Chemical reports loss on weak demand in automotive sector, forecasts full-year net loss

Mitsubishi Chemical Holdings reports a net loss of Yen 49.68 billion (USD474.7 million) for the company’s fiscal first half ended 30 September, swinging from net income of Yen 81.3 billion a year earlier, according to Chemweek. Petrochemical PET Recycling Packaging

Mitsubishi registered a third-quarter operating loss of Yen 28.1 billion, compared with an operating profit of ?130.5 billion a year earlier. Revenue decreased 17.6% year on year (YOY) to Yen 1.5 trillion. The company says that during the first half of the fiscal year, demand was slower YOY, particularly for automotive applications, owing to the impact of the COVID-19 pandemic. Notwithstanding a recent pickup in demand, business conditions remain challenging, says Mitsubishi.

Sales decreased by 16% YOY to ?473.6 billion at Mitsubishi’s performance products business. Operating income plunged 46% YOY to Yen 21.4 billion. Functional products’ revenue declined because of reduced demand principally in automotive applications, despite the recent pickup in demand. Sales volumes fell for high-performance engineering plastics and other offerings for advanced moldings and composites.

-BASF increases investment in Pudong site

BASF SE has increased investment in its Pudong site, its Asian headquarters, by opening its first Asian UL laboratory there and upgrading another product development lab.

A UL lab is one recognized by Underwriters Laboratories (UL), a global safety certification company headquartered in Illinois and an authority in testing the safety and quality of plastic products. Petrochemical PET Recycling Packaging

Such lab can cut down the time needed to launch new products.

BASF’s UL lab was part of an acquisition from Solvay, a Belgian chemical company earlier this year.

BASF paid Solvay 13 billion euro to acquire its polyamide (PA) business. Synthetic polyamides are commonly used in the automotive industry, construction, electric appliances, furniture, shoes and clothing.

-Trinseo raises November PS, ABS, and SAN prices in Europe

Trinseo, a global materials company and manufacturer of plastics, latex binders, and synthetic rubber, and its affiliate companies in Europe, have announced a price increase for all polystyrene (PS), acrylonitrile-butadiene-styrene (ABS) and acrylonitrile-styrene copolymer (SAN) in Europe, according to the company’s press release as of 3 November.

Effective Noveber 1, 2020, or as existing contract terms allow, the contract and spot prices for the products listed below rose as follows:

– STYRON general purpose polystyrene grades (GPPS) — by EUR110 per metric ton;

– STYRON and STYRON A-Tech and STYRON X- Tech and STYRON C- Tech high impact polystyrene grades (HIPS) – by EUR110 per metric ton;

– MAGNUM ABS resins – by EUR110 per metric ton;

– TYRIL SAN resins – by EUR80 per metric ton. Petrochemical PET Recycling Packaging

-Sulzer completes PLA plant for B&F PLA

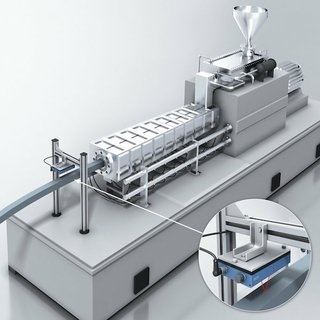

Sulzer Chemtech has supported B&F PLA in the development of China’s first fully-integrated sugar-to-PLA (polylactic acid) plant located in Bengbu, Anhui Province.

The facility utilises Sulzer’s distillation, crystallisation and polymerisation technologies to produce 30 000 tpy of PLA.

The new facility uses glucose from locally sourced corn to produce lactic acid and PLA of different grades, allowing B&F PLA to support the growing bioplastic market. More precisely, the manufacturer is now able to deliver plant-based polymers with different molecular weights and L(+)/D(-) ratios to provide suitable materials for a wide variety of applications. Petrochemical PET Recycling Packaging

Sulzer played a crucial role in the construction of the plant, which was completed in record time. The company designed, engineered and supplied customised mass transfer equipment for the purification of lactide and polymerisation processes. Extensive remote assistance during pre-commissioning, commissioning and start-up was also provided to help B&F PLA begin its operations quickly and smoothly.

-Eco-friendly hangers made by Israeli trash-redeemer UBQ to hit fashion industry

UBQ, which converts household scraps into a bio-based plastic substitute, joins forces with US Mainetti Group to make garment hangers for retail chains globally

Mainetti Group, a maker of clothes hangers for retail chains globally, will join forces with Israeli startup UBQ Materials to use its bio-based products to make eco-friendly hangers.

The joining of forces will “revolutionize sustainability in the fashion industry,” the two firms said in a statement. Petrochemical PET Recycling Packaging

Diamond Green Diesel facility in Norco, La., will more than double its annual production of renewable diesel with the completion of a second Honeywell Ecofining process unit with a capacity of 30,000 barrels per day (bpd). Diamond Green Diesel is owned by Valero Energy Corp. and Darling Ingredients Inc., and is the largest commercial advanced biofuel facility in the United States. Petrochemical PET Recycling Packaging

The Diamond Green Diesel facility converts inedible oils and other waste fats into a high-quality renewable diesel fuel. When the second unit is completed in 2021, the Diamond Green Diesel facility will have capacity to produce 675 million gallons of renewable diesel fuel per year.

Petrochemical PET Recycling Packaging