Petrochemical PETChip Recycling H2 02-12-2020 - Arhive

Petrochemical PETChip Recycling H2

Crude Oil Prices Trend

-Total Corbion outlines most favourable end-of-life options for PLA bioplastics

Total Corbion PLA has released its whitepaper outlining its position on the preferred end-of-life options for PLA bioplastics. The whitepaper also clarifies where PLA products and applications can significantly contribute towards the circular economy.

Total Corbion outlines most favourable end-of-life options for PLA bioplastics

Total Corbion PLA

François de Bie, Senior Marketing & Supply Chain Director at Total Corbion PLA, said: “While the benefits of bioplastics have been known for a while, there are still questions throughout the supply chain on how best to dispose of them after use. This position paper is intended for all interested parties throughout the value chain in order inform not only on the best disposal routes for PLA bioplastics, but also to guide how best to design new products for optimal end-of-life solutions.”

-New recycling capacity in France and Poland to recycle 10 billion PET bottles in Europe by 2023

Indorama Ventures expands facilities Soft Drinks Industry driving value chain investment in recycling – 10 billion post-consumer PET plastic bottles from across Europe will be recycled per year by 2023 in Indorama Ventures’ new and expanded facilities in France and Poland. Thai-based Indorama Ventures Public Company Limited (IVL) is investing USD1.5 billion globally to expand its recycling facilities. The new investment, that will see over 1.7 billion additional post-consumer PET plastic bottles recycled, was welcomed today by UNESDA Soft Drinks Europe, whose members have committed to use recycled PET (rPET) in their bottles. Petrochemical PETChip Recycling H2

“Today we are announcing a new recycling facility in Verdun France and expansion of two recently acquired facilities in Bielsko-Biala and Leczyca Poland. Combined with our existing European facilities, IVL will recycle almost 10 billion post-consumer PET plastic bottles in Europe per year, by 2023. François LAGRUE, Head of Operations – Europe, Indorama Ventures Recycling Group said, This new expanded capacity will mean that, in our facilities alone, an extra 1.7 billion more bottles will be recycled in 2023, compared with 2020. This will lend significant support in realising the EU’s plastic collection and recycling targets.

-China to force firms to submit formal recycling plans and report plastic use

In proposals announced yesterday (30 Nov), China’s Ministry of Commerce said a nationwide system for retailers was to be established to report their plastic consumption.

This will be part of a trial to encourage recycling, which will also mean firms will have to submit formal plans for recycling.

Plastic pollution has become one of China’s biggest challenges, with vast amounts buried or dumped. Petrochemical PETChip Recycling H2

China produced 63 million tonnes of plastic in 2019, with a recycling rate of around 30%.

It produces around 20 million tonnes of single-use non-biodegradable material annually, including 3 million tonnes of shopping bags.

Leading Japanese beverage player Sangaria has been counting on Sidel as a strong partner for more than nine years.

To increase its production flexibility, the company once again turned to its reliable supplier by acquiring the Versatile Sidel Aseptic Combi Predis™ to handle aseptic carbonated and still drinks in PET bottles on the same line. This investment will also support Sangaria to widen its production portfolio in the future. Petrochemical PETChip Recycling H2

In Japan, the local, fast-ageing consumer base is becoming increasingly health-conscious. For food and beverage producers, this puts an increasing focus on the introduction of new, added-value products and demands a careful tailoring of the existing ones to tackle specific needs and expectations around health and packaging functionalities. Alongside, premiumisation is also projected to show strong development in this market.

According to Global Data 2020, enhanced and flavoured water, as well as tea and energy drinks, are the best performing beverages in Japan with substantial forecasted growth in the upcoming years.

-December contract price of ethylene in Europe increased by EUR20 per ton

The contract price of ethylene in Europe for December supplies was agreed at EUR795 per tonne, which is EUR20 per tonne higher than the previous month, ICIS reported.

The contract price was approved on FD NWE terms (delivery to Northwest Europe).

This contract price has been directly confirmed by three producers and two consumers of the material, which is the minimum configuration required for the ethylene contract price to be approved. Petrochemical PETChip Recycling H2

According to ICIS, the cost of the raw material – crude naphtha – remained slightly lower in November than in the previous month, but towards the end of last month it began to rise amid optimism associated with the release of vaccines against coronavirus.

Ethylene supply declined in November compared to October after a series of mostly short-term unplanned breakdowns of cracking units due to technical problems. Another factor that influenced the balance of supply and demand in Europe was the longer shutdowns of the cracking units against the background of higher than expected demand.

German nova-Institute recently published a comprehensive overview of the present status of chemical plastic recycling technologies

Plastic recycling has become a hot topic. The seriousness of plastic pollution has forced itself upon us. Industry, indeed the world, needs to close the plastic loop. But we don’t know how yet. Industry and policy makers will have to mount a concerted effort that includes taxation of fossil carbon in chemicals and materials. In order to ensure an income to the recycling industry, while simultaneously cleaning up the environment.

This is the second article in a series on plastic recycling. We published the first article on November 17. Petrochemical PETChip Recycling H2

Plastic recycling and CO2 emission reduction should not be confused

It is important not to confuse plastic waste policy and climate policy. On this website, we have argued again and again that in comparison to fuel consumption, the amount of carbon stored in materials is small. Plastic recycling will therefore not save us from climate change. Conversely, plastic incineration will not add significantly to global carbon dioxide emissions. Whereas incineration may well be preferable to littering the environment. On the other hand, CO2 capture and utilization (CCU) from such plants will still be a good idea.

-DSM and SABIC co-develop meat packaging material made from mixed post-consumer plastics

With the aim of meeting the demand for more sustainable multi-layer barrier casing solutions, DSM, SABIC, Cepsa, Fibrant, and Viscofan have together created a multi-barrier casing for meat products made via advanced recycling of post-consumer plastics.

Produced by Viscofan, the newly developed casing consists of several layers of different polymers. DSM Engineering Materials supplies the high-performance “certified circular” polyamide (PA) Akulon CRC-MB, and SABIC supplies the high-performance “certified circular” polyethylene (PE) from its TRUCIRCLE portfolio of circular solutions.

Both products are based on used and post-consumer plastics which would otherwise be discarded as landfill or lost to incineration. Petrochemical PETChip Recycling H2

Using advanced recycling, the used plastic is converted into new feedstock, which then enters the production chain to deliver what the companies say are new “virgin-quality” materials.

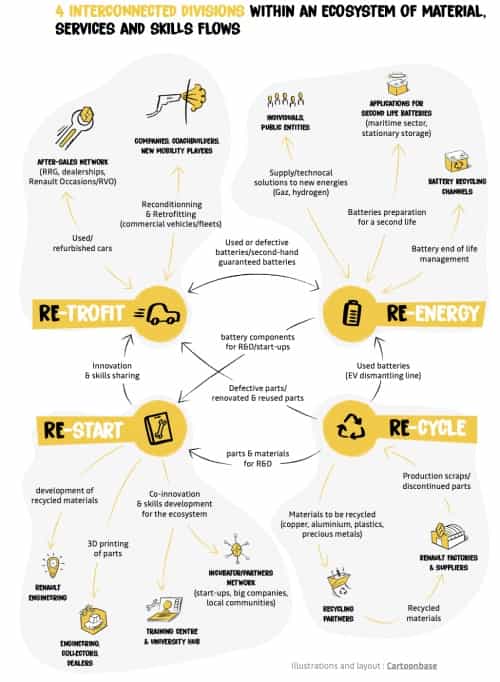

Groupe Renault is creating the REFACTORY in Flins, the first European circular economy site dedicated to mobility. By 2030, it will employ more than 3,000 people in dedicated professions. The implementation of this industrial and commercial ecosystem will take place gradually between 2021 and 2024, replacing the production of new vehicles.

It will be based on a wide network of partners from all sectors and will revolve around 4 poles of activity, putting into practice the principles of the circular economy at each stage of the vehicle life cycle and mobility. Petrochemical PETChip Recycling H2

The circular economy model implemented in Flins will be based on a set of complementary and convergent loops, aimed at encouraging the use of a vehicle instead of its ownership; extending its life through maintenance; and reusing it or reusing its components for other uses, when other solutions are no longer possible.

-Clariter’s Unique Plastic Recycling Solution Achieves a Net Negative Carbon Footprint

Clariter, an international clean-tech company, has announced that its unique plastic recycling solution has achieved a net negative carbon footprint according to the results of a new study, meaning it does not add to, but rather depletes carbon from the planet.

The results stem from an independent initial Life Cycle Analysis (LCA) carried out by CE Delft, the renowned research and consultancy firm. The LCA determined that Clariter’s carbon footprint is below zero indicating a net environmental benefit, with the solution actually reducing carbon emissions. Petrochemical PETChip Recycling H2

The purpose of the study was to better understand Clariter’s sustainability offering to its customers and other stakeholders and to further inform them of its engineering design activities.

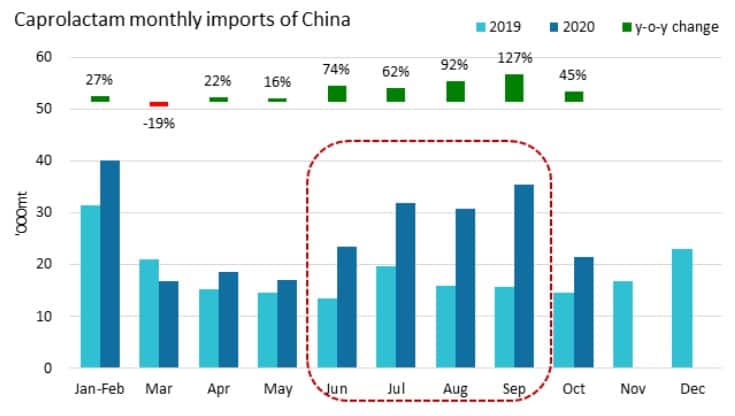

-Reasons about caprolactam imports to China fall greatly in October

Despite of the impact of world COVID-19 pandemic in 2020, China’s caprolactam imports had created three historical record high in July, August and September 2020. Actually the volume had recovered gradually since May 2020, when China imported 16.97kt caprolactam, down 9.07% from last month but up 16% from the same period of last year. The volume soared up greatly in the following four months, and almost surpassed our pre-estimation each time. Petrochemical PETChip Recycling H2

However in October 2020, China imported 21.42kt caprolactam, down 40% month-on-month , but up 45% from the same period of last year. The significant fall in CPL imports in Oct is in line with our expectation, since the market hardly hears any firm conclusion over the past month. But why is such abrupt decrease in October?

Petrochemical PETChip Recycling H2