Petrochemical PETChip Recycling Packaging 04-12-2020 - Arhive

Petrochemical PETChip Recycling Packaging

Crude Oil Prices Trend

Scientists have built tiny droplet-based microbial factories that produce hydrogen, instead of oxygen, when exposed to daylight in air

The findings of the international research team based at the University of Bristol and Harbin Institute of Technology in China, are published today in Nature Communications.

Normally, algal cells fix carbon dioxide and produce oxygen by photosynthesis. The study used sugary droplets packed with living algal cells to generate hydrogen, rather than oxygen, by photosynthesis.

Hydrogen is potentially a climate-neutral fuel, offering many possible uses as a future energy source. A major drawback is that making hydrogen involves using a lot of energy, so green alternatives are being sought and this discovery could provide an important step forward.

-Production capacities for European supplies of protective equipment expanded

Just a few days ago, the second newly-delivered Oerlikon Nonwoven meltblown system was commissioned at Innovatec’s state-of-the-art machine park.

With it, the nonwovens manufacturer – based in Troisdorf in North Rhine-Westphalia – immediately started producing polypropylene filter nonwovens: in particular for use in protective face masks, which have been increasingly in demand since the start of the coronavirus pandemic and whose domestic manufacture is being supported by the Ger-man Government.Petrochemical PETChip Recycling Packaging

Here, the highly-efficient Oerlikon Nonwoven meltblown technology from Neumünster is supporting the production of these highly-effective filter media.

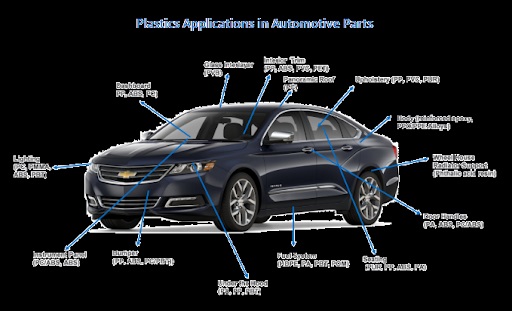

-Understanding The Importance Of Bioplastics In The Auto Industry

Global bioplastic production is projected to rise to 2.43 million tonnes by 2024, according to European Bioplastics

Global bioplastic production is projected to rise to 2.43 million tonnes by 2024, according to European Bioplastics. With its sustainability and vast array of applications, bioplastics are set to take the place of traditional plastics and even metals in all sectors of manufacturing. Let’s take a look at how important bioplastics are in the auto industry.

Origins Of Bioplastics In Auto Manufacturing

Pioneered in 1910, bioplastics use has had a storied history. The first car bioplastics were made from asbestos fibers and wheat gluten. Their use was experimental, however. Bioplastics were limited to minor uses such as being paint ingredients. That was until the 1920s when the technology matured enough. Petrochemical PETChip Recycling Packaging

Glycerol could be derived from soybean oil to serve as shock absorber fluid. Soybean oil was also a critical ingredient in creating substitutes for rubber, which was in high demand at the time.

-Global Tier 1 Sources Waste-Derived Thermoplastics

Global automotive Tier 1 manufacturer Motherson Group is collaborating with Israeli cleantech company UBQ Materials to implement the carbon-negative UBQ thermoplastic into parts manufactured by Motherson Group for the automotive industry.

UBQ is a patented material converted from 100% unsorted household waste, containing food leftovers, mixed plastics, paper, cardboard, packaging materials and diapers. The unsorted waste stream is reduced to its most basic natural components and then reassembled and bound together into a matrix, creating a novel climate-positive material with applications across industries. Petrochemical PETChip Recycling Packaging

By diverting landfill-destined waste, UBQ prevents the emission of methane, groundwater leakage and other environmental harm. Every tonne of UBQ produced prevents 11.7 tonnes of CO2-eq from polluting the environment, leading life cycle assessment auditors Quantis to designate UBQ as “The Most Climate Positive Thermoplastic Material on the Market.”

-Chemical recycling technologies: part of the solution to plastics waste?

Could chemical recycling technologies help bring businesses closer to shaping a circular economy for plastics? A new Quantis report commissioned by the European Chemical Industry Council (Cefic) attempts to answer this question — and more — by taking a critical look at the greenhouse gas emissions (GHG) of chemical recycling and its potential to close the plastic loop. Petrochemical PETChip Recycling Packaging

Plastic recycling rates are strikingly low, with less than 30% of plastics collected for recycling today in Europe. Incremental interventions (a signature of business-as-usual) won’t make a dent in the plastic waste problem. Turning the tide on plastic pollution and avoiding GHG emissions associated with its disposal will require businesses to embrace systemic change, seek out innovative solutions and think outside the box to boost recycling rates. Added to this equation, chemical recycling technologies could help lay the groundwork for a new plastic economy.

-Neste combines bio-waste and chemically-recycled plastic in circular economy-boosting polymers

Finnish oil refining giant Neste is developing polymers without the use of fossil fuels to create what it calls the “future of plastics.”

The material, branded “Neste RE,” is formulated with 100 percent renewable and recyclable materials such as used cooking oil and animal fats from industrial waste.

“As Neste RE is produced of bio-based waste and residues and chemically-recycled plastic waste, it contributes to circular economy,” says the company.

The material also contains recycled PET (rPET) produced through chemical recycling processes. Petrochemical PETChip Recycling Packaging

Neste says the material is designed as a “drop-in” replacement for plastics and can be used on its own or in combination with traditional virgin plastic. The company also claims it is identical in quality.

“Upgrading plastic waste into high-quality polymers and new plastic products reduces the need to tap into virgin fossil raw materials,” says the company.

-PET bottle recycling rate drops in US

The U.S. PET bottle recycling rate declined by a percentage point to 27.9% in 2019, though the amount of RPET used to make new bottles increased.

The recycling rate last year was down from 28.9% in 2018, according to the annual recycling report from the National Association for PET Container Resources (NAPCOR). Last year, 1.77 billion pounds of PET bottles were collected and sold to reclaimers.

For the first time, NAPCOR calculated the combined PET bottle recycling rate for Canada, the U.S. and Mexico: 35% in 2019. Petrochemical PETChip Recycling Packaging

The report also took a look at end markets in recent years. According to a press release, the research showed that from 2017 to 2019 the amount of RPET going into bottles was up 41%. The growth was offset by a 16% drop in RPET going into the thermoform and sheet market during that time, however.

From 2018 to 2019, the amount of RPET going into fiber increased by less than 1% and the amount going into strapping was down by less than 1%, according to the release.

-Toraphene creates biodegradable material containing graphene

A UK-based company, Toraphene, has developed a new material, also called Toraphene, that uses biopolymers that reportedly compost naturally and biodegrade without human intervention, even in the ocean. The biopolymers are combined with graphene – a Nobel prize-winning substance derived from carbon that is stronger than diamond at an atomic level. Petrochemical PETChip Recycling Packaging

“Amidst a climate crisis, plastic waste is known to be a huge, global problem and many plastic alternatives now exist, so why don’t we see them everywhere?”, says Gaute Juliussen, CEO and Founder of Toraphene. “It’s because they need specific manmade conditions to biodegrade, and many degrade into microplastics, which contaminate our oceans and food chain for centuries.

“Such bioplastics have effectively been ‘greenwashed’ and mis-sold to environmentally responsible consumers and companies,” claims Juliussen. “They also tear easily, shorten the shelf-life of the contents they contain and cannot be produced economically at scale.”

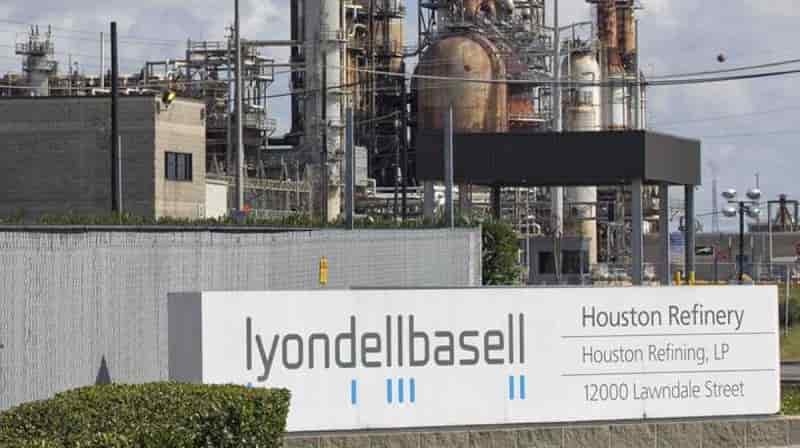

-LyondellBasell, Sasol complete USD2-billion Louisiana JV deal

LyondellBasell and Sasol (Johannesburg) have closed a previously announced USD2-billion transaction that sees the companies form their Louisiana Integrated Polyethylene joint venture (JV) at Lake Charles, reported Chemweek.

LyondellBasell now owns 50% of SasolпїЅs new 1.5-million metric tons/year steam cracker, and low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE) plants – with combined capacity for 900,000 metric tons/year – as well as associated infrastructure at Lake Charles. The deal was closed on 1 December following regulatory and shareholder approvals, with the proceeds to be received within two days of closing, Sasol says. Petrochemical PETChip Recycling Packaging

LyondellBasell will operate the three assets and market the polyethylene (PE) products on behalf of the JV shareholders. Approximately 400 of SasolпїЅs employees at Lake Charles who directly support the assets have now joined LyondellBasell, the companies say. Sasol achieved beneficial operation of the final plant at the Lake Charles Chemicals Project, the 420,000-metric tons/year LDPE unit, mid-November.

пїЅThe formation of this JV is part of our approach to growing our core businesses while positioning the company to benefit from improving economic conditions,пїЅ says LyondellBasell CEO Bob Patel. пїЅWe believe our ability to operate efficiently and serve growing markets will create exceptional long-term value for our shareholders of both companies.пїЅ

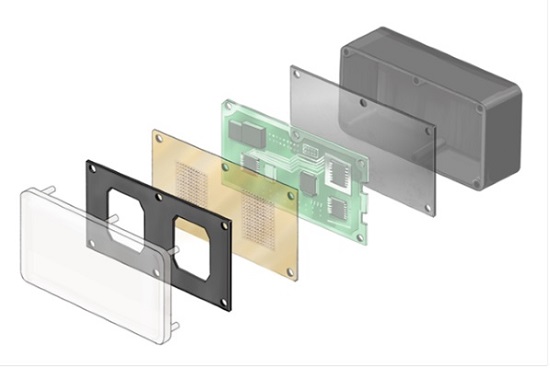

Blow-out of a typical automotive radar sensor with all components faded, except the radar absorbing plate (second component from the left).

SABIC today introduced two new radar absorbing LNP™ STAT-KON™ compounds for automotive radar sensors, significantly expanding its portfolio of these specialty materials. The new grades, based on polybutylene terephthalate (PBT) resin, may be used for integration with radomes manufactured using PBT material, which can provide superior resistance to automotive chemicals. Petrochemical PETChip Recycling Packaging

They complement and extend SABIC’s existing radar absorbing LNP STAT-KON compounds, which are based on polyetherimide (PEI) resin for withstanding higher processing temperatures or on polycarbonate (PC) resin for general applications that require high durability and a balance of physical properties. The high radio frequency (RF) absorption of these compounds can help increase detection range and improve signal resolution. Through materials innovation, SABIC is contributing to the growth of automotive radar and the design of next-generation sensors.

Petrochemical PETChip Recycling Packaging