Petrochemical SustainableSources Textiles 17-11-2020 - Arhive

Petrochemical SustainableSources Textiles

Crude Oil Prices Trend

-How a Circular Economy for plastics can help the GCC realize its sustainability potential

Enhancing the sustainability of plastic products and applications throughout their life-cycle and further integrating the GCC plastic value chain to create and economically sustain a market for recycled material would be another key step forward in fulfilling the circular economy vision in the region.

The overarching vision of the circular economy for plastics is the reduction in leakage of these valuable materials into natural systems and retaining their value in the economy for as long as possible. The circular economy will be realized by a combination of product design and business model innovation, efficient resource management, collaboration and integration of the plastics value chain, as well as enhanced education and awareness among key stakeholders in the value network.

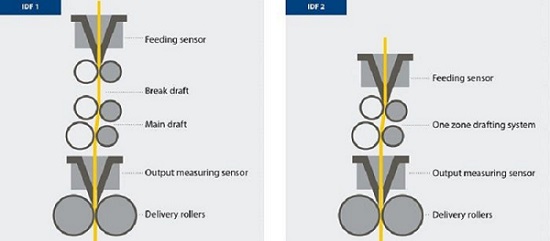

-Integrated Draw Frame (IDF) Direct Spinning – Process Shortening With Technological Advantages

High yarn quality is becoming less and less dependent on the presence and experience of employees in a spinning mill. Nowadays, it is significantly influenced by futuristic plant solutions and intelligent machine systems. Petrochemical SustainableSources Textiles

In the world of spinning, options for shortening processes, and thus reducing outlay in production, are becoming more and more relevant.

One example is the IDF integrated draw frame from Truetzschler which so far is superior to all competitor solutions.

It can be used to combine two important aspects which currently heavily occupy the minds of our customers.

For one, the shortening of processes means lower staff numbers are possible, whilst the IDF also provides a solution for tackling the increasing demand for spinning high-grade yarns from inferior raw material.

-Increase in burning of plastic ‘driving up emissions from waste disposal’

Expansion of energy-from-waste incineration could stop UK hitting its net zero carbon target, campaigners warn Petrochemical SustainableSources Textiles

Carbon emissions from waste disposal are increasing because of the expansion of energy-from-waste incineration plants, a coalition of campaigners has warned.

By 2030 the government’s push to increase incineration of waste will increase CO2 emissions by 10m tonnes a year, mostly from the burning of plastics, the groups said. They argue that the growth in energy-from-waste incineration means the UK will not be able to meet its commitment to net zero carbon emissions by 2050.

SINTX Technologies, Inc., an original equipment manufacturer (OEM) of silicon nitride ceramic for medical and non-medical applications, and Iwatani Corporation of America (ICA), a wholly-owned subsidiary of Iwatani Corporation, announced today that they have entered into a joint development agreement.

The goal of this agreement is to incorporate SINTX AP2 silicon nitride powder into polymer materials. Petrochemical SustainableSources Textiles

These materials will become safe and effective surfaces for IT devices such as cases for cell phones and tablets that are touched frequently.

SINTX and Iwatani aim to create surfaces that resist bacteria and viruses.

The successful development of these products may help prevent and reduce the spread of respiratory diseases like SARS-CoV-2, Influenza A, and H1N1 by inactivating viruses and bacteria on the polymer surfaces.

-Herbold introduces another UK washing line

Herbold Meckesheim has supplied a UK plant with an input capacity of approximately 10,000 tonnes per annum for film recycling.

It is designed for 100 percent post-industrial stretch film. A demanding application for wash lines, as it represents an extremely high surface area and low bulk density.

The plant is another step to cover the growing demands for high quality plastic recycling in the UK. According to the UK Government, an additional tax on plastic packaging is very likely to be introduced in 2022. The initial amount accounts to £200 (~€219) per tonne on packaging which does not include at least 30 per cent recycled material.

One of the highlights of the latest project is the HERBOLD EWS 45/200 shredder, which is used as a pre-shredder prior to the wet granulator. Petrochemical SustainableSources Textiles

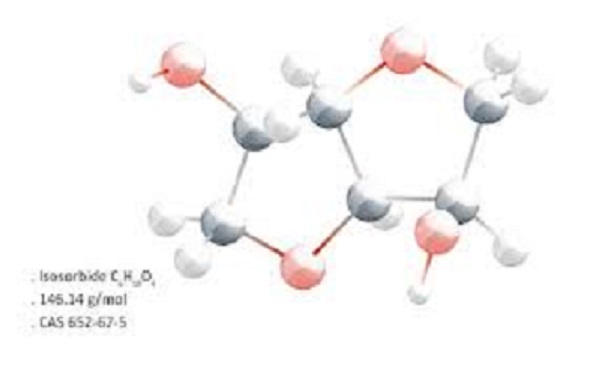

-Introducing isosorbide: a sustainable, safe, high-performance, plant-based feedstock for packaging

Jiae Kim, Global Market Manager, Performance Materials, Roquette, introduces Isosorbide, a plant starch-derived bicyclic diol with rich functionality for a range of applications in packaging, coating, adhesives, sealants and elastomers.

Though often labelled as ‘the problem’ plastic packaging has the potential to become the solution with estimates suggesting that switching plastic out for alternatives, such as aluminium and glass, could result in a 2.7 fold increase in greenhouse gas emissions.1 Establishing a circular economy, in which plastics are efficiently recycled and reused, is essential but so too is the development of new, sustainable feedstocks and high performance materials. Step forward isosorbide. Perfectly safe and produced from an annually renewable feedstock isosorbide has exciting potential for a range of packaging applications. Petrochemical SustainableSources Textiles

-LG Chem develops biodegradable new material

LG Chem successfully developed a new biodegradable material that could realize mechanical properties equivalent to synthetic resins, according to GV.

Thus, LG Chem has recently developed a new material that significantly improved flexibility (elongation) and transparency compared to existing biodegradable materials through proprietary technologies and production processes.

The new material developed by LG Chem is said to be the only single biodegradable material with 100 % bio contents using corn-based glucose and crude glycerol and it is the only material in the world that manifested mechanical properties and transparency equivalent to synthetic resins such as PP (polypropylene).Petrochemical SustainableSources Textiles

-Footprint launches sustainable takeaway food container

Footprint, a sustainable technology firm specializing in materials science engineering, today announced the launch of its new, plant-based clam-shell food container available for order now.

As takeout orders and disposable food container use rises during the pandemic, this plastic and PFAS-free alternative meets the expectations of food providers and customers without sacrificing quality or convenience. Petrochemical SustainableSources Textiles

Continuing its mission to create a healthier planet and healthier people, Footprint’s new, molded fiber, plant-based clamshell container will not only reduce unnecessary waste from entering the environment, but also reduce exposure to toxic chemicals found in plastic.

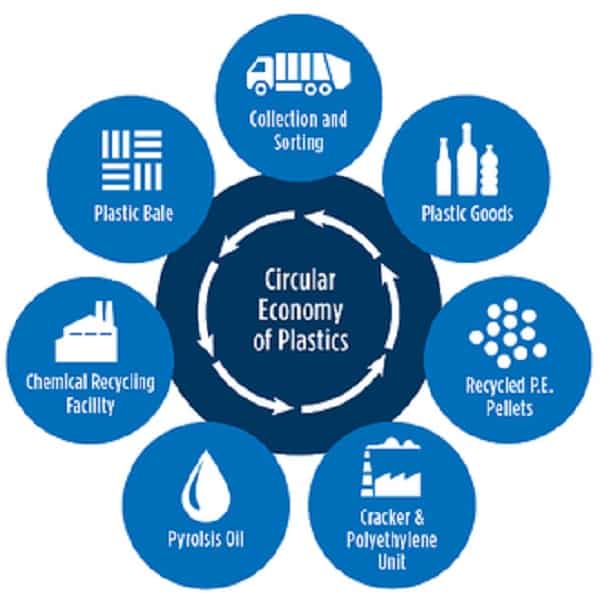

-Molecular Management and the Circular Economy of Plastics

Demand and desire for more recycled content in useable goods continues to rise. An idealized circular economy of plastics implies that plastic molecules are recycled back into plastic goods directly: For example, mixed plastics are collected, processed in a recycling facility, fed to a cracker and polyethylene (PE) unit, turned into plastic pellets again, used to produce goods, then collected and the goods are recycled to start the process over. A similar cycle could be shown for polystyrene, PET or other recyclables.

The reality, including tracking molecules and accounting for recycled content, is actually more complex and difficult to manage. But with an ultimate goal of increased sustainability in the industry, molecular management is needed. Petrochemical SustainableSources Textiles

Let’s utilize mixed plastics recycling as the basis of our discussion. Currently, the amount of pyrolysis oil being produced from recycled plastic chemical processing is relatively small in comparison to the amount of feedstock needed to supply a typical cracker and PE unit.

-Commodity Resin Prices End the Year Mixed

Overall, processors will have more leverage in 2021 contract negotiations.

Prices of the five large-volume commodity resins were generally on an upward trajectory through at least the end of the third quarter, owing to a combination of factors including planned and unplanned capacity interruptions that limited feedstock and/or resin inventories, spikes in feedstock costs and, in some cases, strong demand.

Approaching the end of the year, the trajectory appears to be flat with potential for downward movement for PP, PS, and PET that could result from improved supplier inventories, lower feedstock costs and slowed demand.

Overall, plastics processors were expected to have greater leverage in negotiating 2021 contracts. Petrochemical SustainableSources Textiles

–PLA FIBER – Video

It is biodegradable feature, and it has Flame retardant feature, a good choose for baby product.

Petrochemical SustainableSources Textiles