Petrochemicals Biobased Resources PEF 19-08-2021 - Arhive

Petrochemicals Biobased Resources PEF

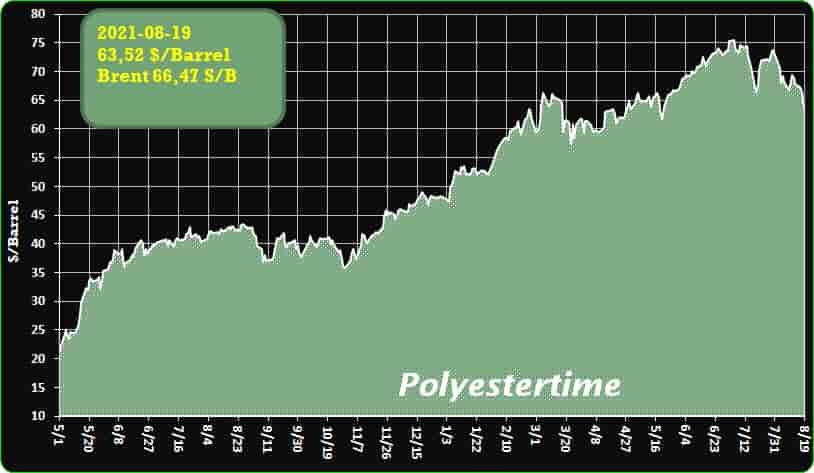

Crude Oil Prices Trend

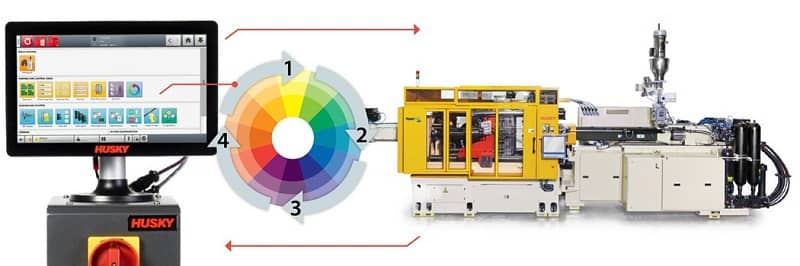

A collaboration between Husky and Chem-Trend led to the development of the new controller functionality that focuses on automation to optimise colour change processes. EPPM spoke to Matthew Cummings, Product Manager, Mold Controllers, at Husky to learn more.

How will the development of Altanium benefit the operator, and what effect does it have on the final product?

Every machine, every application has different or unique colour change parameters. We’re enabling customers to find a process that works best in their moulding operation. The operator can then be prompted during a colour change so that it’s followed exactly, and they can get much more consistent results with the materials they’re using.

It’s just such an important performance metric and requirement for a lot of our customers. More and more we see customers requiring very high performance with respect to colour change processes. Changing colour within this same given production cell is just so common that if you can shave different elements of time from their changeover process, it can represent significant cost savings.

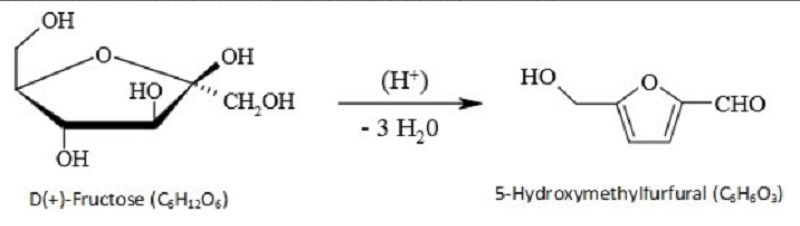

-Great potential for biological residues

Huge amounts of waste are produced both during food production and by consumers. The Conversion Technologies of Biobased Resources group at the University of Hohenheim’s Institute of Agricultural Engineering has developed a process to convert this biomass into hydroxymethylfurfural (HMF), the highly potent basic chemical that is used to produce plastics. Petrochemicals Biobased Resources PEF

Every year, around 12 million tonnes of food are thrown away in Germany.1 Most of the waste (52%) is generated in private households because the food is old, ugly or spoiled. However, considerable quantities of waste are also generated before they even reach the consumer: fruit and vegetables are often sorted and discarded in the field if they do not meet the standard expectations in terms of size, shape or colour and therefore cannot be sold (12%).

Leftovers from industrial food processing end up in the bin (18%), as do leftovers from restaurants and canteens (14%). As much as four percent of the waste is generated in the retail sector due to damage during transport or storage.

Although energy is still obtained from the discarded material through incineration or conversion in biogas plants, it is not particularly sustainable, as significantly more resources (energy, water, nutrients) are used to produce the food.

-Avantium Announces First Half 2021 Results

Company Makes Commercial Progress while Financing Discussions for the FDCA Flagship Plant Continue

Avantium N.V. (Euronext Amsterdam and Brussels: AVTX), a leading innovative chemical technology company dedicated to developing and commercialising proprietary technologies for the production of chemicals from renewable sources, today reports its 2021 half year results.

Key Business Developments in the First Half of 2021:

- Avantium Renewable Polymers continues to work towards making a Final Investment Decision (FID) concerning the potential construction of the planned FDCA (furandicarboxylic acid) flagship plant:

- Negotiations with banks and other parties continue around FDCA flagship plant funding.

- Avantium and a European feedstock provider have reached agreement on the terms of a strategic supply contract of high fructose syrup feedstock.

- Bas Blom is appointed Managing Director of Avantium Renewable Polymers, effective 15 August 2021.

- Avantium Renewable Chemistries made continued progress towards commercialisation with its Ray Technology™:

- Avantium and Cosun Beet Company announced the ambition to jointly construct and operate the first commercial plant for the production of plantMEG™ (mono-ethylene glycol) and plantMPG™ (mono-propylene glycol).

- Successful production of PEF (polyethylene furanoate) and PET polyesters with plantMEG™ from the Ray Technology™ demonstration plant. Petrochemicals Biobased Resources PEF

- Avantium Catalysis recorded revenues of €4.3 million in the first half of 2021 (HY 2020: €4.0 million), with continued impact from COVID-19 travel restrictions.

- Today, Avantium announced that Mr. Nils Björkman has been nominated for appointment to its Supervisory Board for a term of four years.

-Resin Markets Nearing Inflection Point

The plastics market should reach the apex of the resin-ridden rollercoaster and into a period of more balanced supply and demand fundamentals.

For resin producers in North America, 2021 has truly been a banner year, although those at LyondellBasell, Dow Chemical, and other major producers in charge of resin shipping logistics might have a few words to the contrary.

Still, the recent earnings calls hosted by resin producers have been buoyant to effervescent in tone amid high earnings and robust margins. As is typical of these situations, the presentations were awash with sentiment that resilient consumer demand and disrupted logistics will continue to keep resin supply tight and margins strong. Petrochemicals Biobased Resources PEF

And that may well be the case — no one really thought we would be having six consecutive months of US polyethylene (PE) contract price increases through July, but here we are. However, absent a major market-moving weather event such as a US Gulf Coast hurricane knocking a hefty amount of polymer production offline, we should be at the apex of the rollercoaster ride that has been PE, polypropylene (PP), and polyethylene terephthalate (PET) pricing over the last several months and headed into a period of more balanced supply/demand fundamentals.

-LyondellBasell joins Cyclyx as founding member

Cyclyx International, a consortium-based feedstock management company with a mission to increase the recycling rate of plastic from 10% to 90%, has announced that LyondellBasell has joined Cyclyx as a founding member. LyondellBasell, one of the world’s largest producers of plastics and chemicals, is a leader in the effort to help advance the circular economy and has pledged to produce and market two million metric tons of recycled and renewable-based polymers annually by 2030.

As a founding member of the consortium, LyondellBasell will join the collaborative efforts of a growing list of companies that are working to foster a more sustainable future for plastics.Petrochemicals Biobased Resources PEF

The company has consistently demonstrated their commitment in this area, leveraging their scale and reach to make a positive impact across the value chain. With multiple investments in recycling technologies and collaborations focused on advancing recycling infrastructure and end markets for recycled products, LyondellBasell’s membership brings valuable knowledge and experience to Cyclyx. In addition, Ganesh Nagarajan, associate director, polymers business development and projects at LyondellBasell will bring his expertise to the executive advisory board.

“As a founding member of Cyclyx, increasing the recycling rate of plastic waste is incredibly important to our sustainability journey,”said Ken Lane, LyondellBasell executive vice president Global Olefins and Polyolefins. “LyondellBasell recognizes the challenges plastic waste brings, and we aim to be a part of the solution through our involvement with Cyclyx, which can help us and our industry achieve our recycling ambitions.”

-This makes injection moulding for small batches economical

In medical, diagnostic and analytical devices, in industrial automation as well as in development processes, precise plastic parts are needed in small series. Injection moulding is usually out of the question due to the high tooling costs. With a new technology from Bürkert, this manufacturing process is now economical from as little as 250 units produced. Petrochemicals Biobased Resources PEF

The quality of the material and the flushability of the channels have high priority in analytical equipment for in-vitro diagnostics, but also in other procedures in which gases or liquids are precisely distributed; after all, the accuracy of the systems depends on this. At the same time, however, economical solutions are also required. Especially with small series, it is a challenge to keep production costs low. Bürkert Fluid Control Systems in the Criesbach system house proves that quality and economy are not mutually exclusive with a standardised, modular plastic injection moulding technology that is suitable for small series with quantities between approx. 250 and 2,500 units.

-DS Smith studies viability of using seaweed as alternative fibre source for packaging

DS Smith is determining if seaweed fibres can be used as a raw material in paper and packaging products amid increasing demand for recyclable goods from business customers and consumers. Petrochemicals Biobased Resources PEF

In what the company says is an industry first, DS Smith could use seaweed across its packaging network as an alternative fibre source to wood. After initial testing, the company also is researching seaweed’s potential role as a barrier coating, replacing problem plastics and petroleum-based packaging used to protect food.

DS Smith is talking to several biotechnology companies to explore the potential use of eco-friendly seaweed fibres in a range of packaging products, such as cartons, paper wraps and cardboard trays.

-Huhtamaki acquires Turkish plastic packaging manufacturer Elif Holding

Huhtamaki (Finland) has signed an agreement to acquire Turkey’s Elif Holding A.S., a major supplier of environmentally friendly flexible packaging, for EUR412 mn (USD483 mn), the company said in a statement.

In a press release, the company notes that the acquisition is in line with the Finnish packaging manufacturer’s growth strategy to 2030 in terms of geographic reach, technological capabilities and product mix. This allows Huhtamaki to expand its flexible packaging production capacity in Turkey, which the company considers to be one of the countries with the greatest growth in the future.

The Elif business will become part of the company’s Flexible Packaging business segment. Bridging financing for the USD500 mn acquisition of Elif is supported by Citibank, which also acted as a consultant on the transaction.

In addition, the two companies share similar commitments in three areas: environmental, social and corporate, and in supporting their clients to achieve their sustainability goals. Petrochemicals Biobased Resources PEF

The deal is subject to Turkish antitrust approval and is expected to close after regulatory approval. Both companies will continue to operate as usual until the closure.

Earlier it was reported that Finnish Huhtamaki Flexible Packaging Europe received approval from the European industry group RecyClass (Belgium) for its three new laminated polyethylene tube technologies, developed in collaboration with Czech company Zalesi and toolmaker Plastuni Lisses, part of the Somater Group. Tubes made with this technology from HDPE with easy to apply direct printing have been tested in an independent laboratory.

-Dow Accelerates Collaboration with Auto Industry

Dow has launched its MobilityScience Studios to support the development of innovative transportation technologies. The first two studios, located in Midland, MI, and Lake Jackson, TX, offer a collaborative workspace that features a world-class suite of testing capabilities focused on acoustic and powertrain solutions for automotive applications. These enable Dow to create tailor-made noise, vibration, and harshness (NVH), sealing, powertrain, and fluid transfer system solutions unique to any specifications.

Through an integrated approach, MobilityScience Studios foster collaboration to provide customers with solutions ranging from custom product formulations to factory line implementation. Petrochemicals Biobased Resources PEF

“Our MobilityScience platform was created to improve our service, accelerate innovation, reduce complexity, and better connect customers with our products and capabilities,” said Tim Boven, MobilityScience Growth Director. “MobilityScience Studios offer a comprehensive development network that combines collaboration spaces and access to experts with formulation, fabrication, and testing capabilities to deliver better, more innovative, and more sustainable mobility solutions to market faster.”

-Polimekh launched a PET bottle recycling line in Kazakhstan

The Polimech company (Moscow, Polimech) has launched a line for the processing of used PET bottles, as well as a line for the production of polymer-sand products in the Atyrau region of Kazakhstan, the company said.

The line includes equipment for pretreatment of PET bottles, several stages of washing (including the hot stage), drying and separation, which makes it possible to obtain pure PET-flex. Petrochemicals Biobased Resources PEF

The combination of the use of two lines at once makes the production waste-free, which allows you to get the maximum profit, the company notes.

Earlier it was reported that in December last year Polimekh launched a line for the processing of highly contaminated film materials with a capacity of 500-600 kg / h in the Moscow region. The line includes a washing and drying complex of the latest generation with automatic removal of dirt and a highly efficient press-pressing for drying film materials, as well as a fully automatic granulation line with a thermal compactor, a non-stop melt filter with self-cleaning, and automatic filling into big bags.

Petrochemicals Biobased Resources PEF