Petrochemicals Chemical Recycling Film 18-10-2021 - Arhive

Petrochemicals Acrylonitrile Polyester Filament

Crude Oil Prices Trend

-Brückner Maschinenbau places major order with Coperion

Brückner Maschinenbau has placed an order with Coperion for more than 50 ZSK Mc18 twin screw extruders. These will be integrated into plants for the production of flexible BOPET packaging films, which Brückner will install in China.

Brückner Maschinenbau’s substantial repeat order is based on many years of close co-operation with Coperion. With this order, Brückner is placing its trust in proven Coperion technology, which the company has already integrated into numerous film stretching lines. Due to the ZSK extruders’ high torque, Coperion’s technology achieves very high throughput rates while maintaining low product temperatures and thus ensuring product quality.

Jochen Schofer, Business Segment Manager Recycling and Direct Extrusion at Coperion, said: “We are very pleased that Brückner Maschinenbau is once again relying on our technology and know-how. We very much appreciate this familiar, long-standing co-operation with the pioneer for plastic film lines. Our companies pursue very similar aspirations. We both develop high-quality technologies for plastics production with very high throughput rates. The efficient use of resources and high recyclability of the end products are important to us.”

Global brand merger under TECHNYL® to improve visibility of same best-in-class products

A full set of new qualifiers highlight customer benefits, simplifying purchasing

DOMO will exclusively produce and commercialize the expanded TECHNYL® brands globally from February 2022

Following the acquisition by DOMO Chemicals of Performance Polyamides Business (Polytechnyl) in Europe – including the well-known TECHNYL® brand – all current DOMAMID®, ECONAMID® and THERMEC™ branded engineered materials solutions will be merged under one TECHNYL® umbrella worldwide.

The move, which goes live early next year, will improve the visibility of DOMO’s best-in-class portfolio of PA6 and PA66 solutions, including a full set of new product qualifiers to simplify customer purchasing.

“This step is all about serving our customers and partners and capitalizing on the strong heritage of TECHNYL®. With sole global supply, our widened portfolio of tailored engineered materials solutions, and the 360° services that address our customer needs, we will better serve a variety of segments with undisputed expertise, opening new opportunities for innovation and collaboration,” said Philippe Guérineau, DOMO’s Chief Commercial Officer Europe and Europe Export The new brand architecture will be effective from 1 February 2022, when the TECHNYL® brand will be distributed exclusively by DOMO Chemicals at a global level.

-Capital spending of US$300 bn for “Circular Plastics Economy” by 2050

Around US$1.5 trillion in investment by the global plastics industry would be required to meet growing demand for consumer plastics to 2050, and of this more than US$300 billion can be redirected to mechanical and chemical recycling processing capacity thereby meeting the goals of an aggressive circular economy case, according to research firm IHS Markit analysis.

Under current market trends, progress towards a circular economy for plastics would be modest, relying primarily on mechanical recycling. More ambitious goals, targeted at reducing the practices of landfill, incineration and energy recovery as end-of-life solutions for waste plastics may be achievable by redirecting a portion of new manufacturing investment towards a wider range of plastic recycling facilities, including both mechanical and chemical recycling, especially as the latter become more economically feasible.

-Plastics Recycling Show Europe announces conference programme

The Plastics Recycling Show Europe (PRSE) conference programme has been published ahead of the event’s return to the RAI Amsterdam on 4-5 November 2021.

Virginijus Sinkevičius, Commissioner for Environment, Oceans and Fisheries at the European Commission will deliver the opening keynote updating delegates on the latest political and legislative developments in plastics recycling in Europe. Additional speakers in the opening session entitled are PRE President Ton Emans and Peter Goult, Associate at SYSTEMIQ.

Prominent speakers from major brands at the plastics recycling conference include Thor Tummers, External Affairs manager at Unilever, Eelco Smit, Sustainability Leader at Philips Domestic Appliances, Gian De Belder, Technical Director – R&D Packaging Sustainability at Procter & Gamble, and Anne Guillou, Sustainable Packaging & Product Development Manager, L’Oréal, among others.

Materials focus sessions on the first day will explore the challenges, issues and opportunities within the sector for mechanical recycling, covering PET, PVC, Technical Plastics and Polystyrene (PS) recycling.

-Rabobank casts investor’s eye on chemical recycling

Global bank issues report saying ‘advanced’ recycling is gaining investor attention despite criticism of its environmental credentials.

Chemical and other not fully mechanical plastic recycling methods, sometimes referred to by supporters as “advanced recycling,” remains a “highly attractive investment opportunity” for some companies and financiers, according to Netherlands-based Rabobank. Investments are gaining speed in Asia in particular, adds the bank.

Rabobank published a report earlier this year forecasting that by 2025 there could be 140 advanced recycling plants worldwide with a total capacity of up to 4 million metric tons. “Since then, many opponents of advanced recycling [have] raised their voices,” says the bank.

“They argue, for example, that the technology is still unproven and too costly, that it has a worse-than-advertised environmental performance, that there is no traceability in the system, and that planned investments are forever being delayed,” continues the European bank.

(Thermo-)chemical recycling is a process used to decompose waste into valuable products. From plastic waste, it is therefore possible to obtain raw materials such as fuels, oligomers/polymers, as well as basic raw materials and gases (P to L, P to C, P to G). Certech has specific skills and facilities needed to reach the requested reaction conditions.

Pyrolysis

Certech is equipped with laboratory-scale reactors, used for exploratory tests aimed at optimizing the reaction and operating conditions on a hundred grams of waste : liquid, solid and gaseous product characterizations, mass and energy balance, etc.

Mechanically stirred pilot reactors (5 and 20 L) allow to evaluate the process on a larger scale, in a batch or continuous mode.

Certech has many years of expertise in the field of pyrolysis for the transformation and energy recovery of waste into fuels or hydrocarbons, notably by participating in the technology transfer of a patented process aimed at recycling more than 35 000 tons/year of automobile shredding residues.

-Baerlocher expands its UK operational Capacity to support local PVC Market

Baerlocher, a leading global manufacturer of additives for the plastics industry, is investing in its production plant in Bury. The company will increase capacity of its Calcium based PVC stabiliser plant by more than 50% with installation of additional new Mixing and Granulation units in 2022.

This expansion will support the strong demand in all new and recycled PVC applications and reinforces the company’s commitment to the ‘post Brexit’ UK and Irish markets.

Andy Jones, the group’s Global PVC Additives Head stated: “For the past 25 years, the Bury site has established itself as the premier solid PVC stabiliser production plant in the UK. This expansion begins the next chapter for the company, as we approach our 50th anniversary in the UK during 2023, with an increasingly challenging regulatory framework and complexity in supply chains”.

“Our Customers rely upon local security of supply, product consistency and speed of response from established and reliable sources” according to Andrew Tate, Head of PVC Additives EU/MEA, “The capacity increase delivers on this need, and will also support the anticipated new demand for solid Ca based systems, due to increasing regulatory pressure to convert from existing liquid stabilisers, in many PVC applications.”

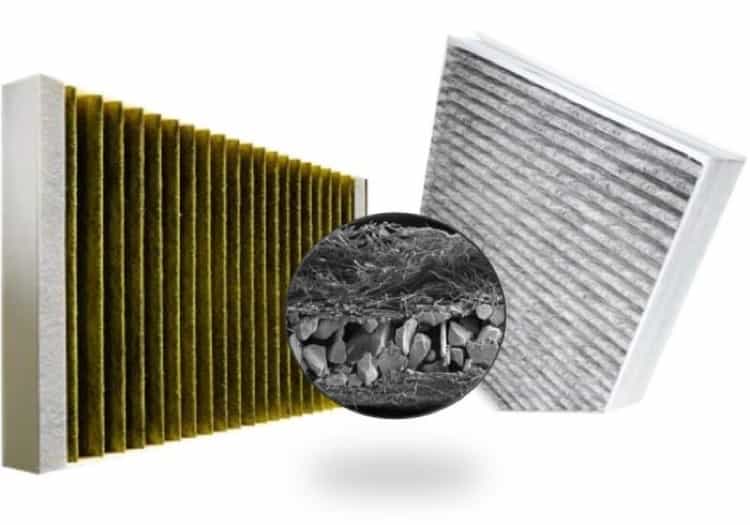

-Benefits with activated carbon

Mann+Hummel combi filters for vehicle interiors contain activated carbon to protect against harmful gases and unpleasant odours. Field studies in cooperation with the University of Heidelberg in Germany have shown that when a combi filter is used, the concentration of nitrogen dioxide in the vehicle interior is reduced by more than 90%.

Cabin air filters in vehicles play an essential role when it comes to effective health protection. Despite modern exhaust gas purification systems in accordance with the Euro 6 standard, combustion engines still produce gases that are harmful to health, such as certain hydrocarbons and nitrogen oxides. Emissions from vehicle interior materials including toluene and aldehydes can also pose a health risk when volatile organic compounds in the form of aldehydes are out-gassed from vehicle interior materials. On some days, the ozone concentration of the outside air is an additional burden for the human organism.

“We have noticed that cabin air filters in vehicles are given far too little attention in the public debate,” said Christoph Hitzke, cabin air filter development manager at Mann+Hummel.

-Pregis Opens New Packaging Film Extrusion Facility

Sustainability figures prominently in both the new Andersen, S.C., building and the materials produced within it as part of Pregis’ 2021 $140 million capex investment in new production capabilities.

Pregis, a supplier of packaging and protective materials, has opened its newest facility in Andersen, S.C. The 168,500-sq.-ft. manufacturing site marks an $80 million investment by the company to create what Pregis calls “a new state-of-the-art film extrusion facility to manufacture performance-oriented, flexible packaging solutions for food, consumer packaged goods, and medical device applications.”

At the ribbon cutting event to mark the opening of the new facility, Kevin Baudhin, president and CEO of Pregis Corp., said, “Packaging is a critical part of the economy and that’s why we’ve been active in opening new plants—seven globally, three of which are in the U.S.” He added that Pregis has spent $140 million in capex for its plants in 2021.

Unrecyclable chemical Recycling Technology 16-10-2021