This content has been archived. It may no longer be relevant

Petrochemicals CircularEconomy Adipic Acid

Crude Oil Prices Trend

-Using wood for textiles – More conscious than some think

We recently ran a consumer survey on a number of things related to consumer attitudes towards sustainability in textile materials, textile raw materials and emerging materials like our wood-based fibre.

Made in four European countries and the US, the survey gives us intriguing insight to all this. We will disclose the entire results in the near future, but here’s a sneak peek, as I wanted to first address a misconception that we often hear and was also visible in the survey results.

Firstly, we were glad to see that 86% of all respondents found wood a “very” to “somewhat sustainable” raw material for textiles. However the 86% includes 37% that answered “somewhat sustainable” and 15% said they don’t think wood is sustainable at all, so there are some concerns and that’s fine. Being worried about overusing wood only shows awareness.

-LC Packaging makes circular economy pledge

The German arm of a Dutch flexible packaging firm has pledged its commitment to the circular economy by signing-up to the Prevent Waste Alliance.

LC Packaging GmbH said joining the Alliance would help it contribute to minimising waste and maximising the reuse of resources on a global scale.

By working in partnership with other Alliance members, which include other businesses, public institutions and academia in Germany, the company will work towards “conserving resources and closing loops” around packaging. Petrochemicals CircularEconomy Adipic Acid

-Pak govt urged to waive tax on partially-oriented yarn

The Federation of Pakistan Chambers of Commerce & Industry (FPCCI) recently urged the government to waive the 37 per cent tax on partially-oriented yarn (POY 5402.4600), the basic raw material for the textile industry and small and medium enterprises, so that investors can be encouraged to set up draw textured yarn (DTY) manufacturing plants.

Local production can meet the demand for raw materials of the domestic industry, chairman of FPCCI standing committee on imports Khawar Noorani said.

He expressed deep concern over the equal tax rate on imported POY and DTY. The government imposes 11 per cent customs duty, 2 per cent additional customs duty, 2 per cent income tax, 2.5 per cent regulatory duty, 17 per cent sales tax and 3 per cent additional sales tax on POY imports, which is 37 per cent of the total tax, while the tax rate on DTY is also same and this is unfair as the duty on POY is less all over the world, he was quoted as saying by Pakistani media reports. Petrochemicals CircularEconomy Adipic Acid

Europe intends to be a world leader in the circular economy and in clean technologies. Chemical recycling can act as game changer by recycling much more plastic waste and serving plastic products containing recycled content to a broader range of markets.

Today, just 15% of EU-collected plastic waste finds its way back into the EU plastic market. Mixed or contaminated plastic waste is currently incinerated, ends up in a landfill or litters our streets and waters. Petrochemicals CircularEconomy Adipic Acid

Chemical recycling technologies can be part of the solution since it can use waste plastic streams that currently have no or low value in recycling, thus present an addition to the already existing mechanical recycling of plastics.

It can also potentially remove the so-called “legacy chemicals” and substances of very high concern (SVHC) from plastic waste.

-“Chemical Recycling – what it is, and what it is not?”

Interview with Daria Frączak, R&D Manager at Clariter about chemical recycling – what it is, and what it is not? Petrochemicals CircularEconomy Adipic Acid

Daria is a speaker at the upcoming online Go Circular Petrochemicals conference. She will speak about chemical recycling technology at Clariter: plastic waste into value

-ADIPIC ACID – Bacteria may be key to sustainable nylon production

Scientists are creating adipic acid without the byproduct of greenhouse gases

The discovery that bacteria that can be used to make a key chemical used in nylon manufacturing could allow for the creation of this component without the emission of greenhouse gases. Petrochemicals CircularEconomy Adipic Acid

Scientists at the University of Edinburgh have developed a sustainable method for making adipic acid, which is a key component of nylon. The scientists altered the genetic code of E.coli. The modified cells were grown in liquid solutions containing guaiacol, which is the main component of compound that gives plants their shape. Following a 24-hour incubation period, the modified bacteria transformed the guaiacol into adipic acid, but without producing nitrous oxide.

Scientists warn prevalence of plastic pollution may pose risks to human and ocean health

More than 10 times as much plastic has been found in the Atlantic ocean than previously estimated to be there, showing the the world’s plastic problem is likely to be much greater than realised. Petrochemicals CircularEconomy Adipic Acid

New measurements of the top 200m of the Atlantic found between 12 and 21 million tonnes of microscopic particles of three of the most common types of plastic, in about 5% of the ocean. That would indicate a concentration in the Atlantic of about 200 million tonnes of these common plastics.

Previous estimates, based on calculations of the amount of mismanaged municipal waste in coastal areas, were that between 17 million and 47 million tonnes of plastic had been released into the Atlantic in total over the 65 years from 1950 to 2015.

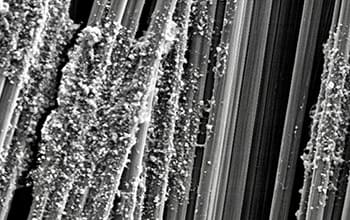

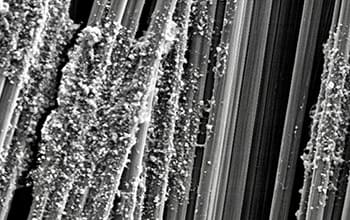

Researchers use a natural plant product to coat and pin carbon nanotubes uniformly

In current technology, polymers reinforced with ultra-fine strands of carbon fibers represent a class of composite materials that are “as light as a feather and as strong as steel,” leading to versatile applications in several industries. To increase strength and give carbon-fiber composites other desirable properties such as high electrical and thermal conductivities, carbon nanotubes are often added. Petrochemicals CircularEconomy Adipic Acid

However, the chemical processes used for incorporating the carbon nanotubes into these composites often cause the nanotubes to spread unevenly and clump, reducing the overall benefit.

To facilitate the even distribution of carbon nanotubes, researchers in a U.S. National Science Foundation-funded study at Texas A&M University used natural plant products called cellulose nanocrystals to coat and pin carbon nanotubes uniformly into the carbon-fiber composites.

RadiciGroup and Atalanta B.C. have announced the continuation of their partnership during the 2020-2021 football season.

In the next few days, they will publish the details of their collaboration – a testimony to their shared values and, above all, their deep attachment to the territory and communities of the Province of Bergamo. Petrochemicals CircularEconomy Adipic Acid

Maurizio Radici, Vice President of RadiciGroup, said: “We are tightly bound to the Nerazzurri jersey. The Atalanta jersey is the symbol of a territory and of a population that is rich in values and aware of its traditions, that works hard with determination to achieve important objectives. At a time like this, in which Bergamo has been put to a tough test, we think it is even more important for local pillars of society to team up, so as to reach increasingly more ambitious goals.”

-DS Smith and Aquapak Target Single-Use Plastic Packaging Reduction with Biodegradable Alternative

Scientific collaboration between DS Smith and Aquapak Polymers aimed at commercializing groundbreaking sustainable single-use packaging solutions.

A scientific collaboration between Atlanta-based DS Smith, a leading sustainable packaging company, and U.K. developer of innovative biodegradable polymers Aquapak Polymers, is expected to result in the development of next-generation single-use packaging solutions– a fully recyclable packaging alternative to non-recyclable plastics.

Now that they have completed the pilot project stage, the partners are working on practical applications of the combined, biodegradable materials with a focus on recyclability and performance. Petrochemicals CircularEconomy Adipic Acid

This includes a range of packaging solutions where traditional plastic films can be replaced with Aquapak’s Hydropol, a biodegradable and water-soluble polymer that will help improve the recycling process and result in less contamination, as it is designed to dissolve completely in warm or hot water.

Petrochemicals CircularEconomy Adipic Acid

Petrochemicals CircularEconomy PET Textile 20-08-2020