Petrochemicals CrudeOil BOPP 13-10-2020 - Arhive

Petrochemicals CrudeOil BOPP

Crude Oil Prices Trend

-The world’s first carbon-neutral rPET

ALPLA has switched its PET Recycling Team plants in Wöllersdorf, Austria, and Radomsko, Poland, to a mix of electricity from renewable sources in order to produce carbon-neutral.

Georg Lässer, Head of Recycling at ALPLA, said: “This step has already had a big impact on the carbon footprint of our food-grade regranulate – according to the calculations, emissions are cut by up to 90 per cent compared with virgin material. The feedback from the market regarding this further development has been very good.”

The company is now offering carbon-neutral rPET based on the purchase of certificates. The remaining, unavoidable emissions will then be offset with carbon certificates.

-Carbios acquires Limagrain Ingredients’ stake in Carbiolice

Carbios has announced the acquisition from Limagrain Ingredients of its entire stake in the capital of Carbiolice, a joint company created in 2016 around an enzymatic biodegradation technology licenced Petrochemicals CrudeOil BOPP

The acquisition of Limagrain Ingredients’ equity took place on 8 October. This strategic transaction highlights the confidence in Carbiolice’s growth potential and Carbios’ intention to remain its long-term reference shareholder. It also reinforces Carbios’ ambitions to position itself as the world leader in biological technologies for the end-of-life of plastics and synthetic fibres. In addition to the enzymatic recycling process developed in-house by Carbios, the PLA biodegradation technology implemented by Carbiolice will enable the commercialisation of a new generation of compostable plastics, making it possible to achieve zero waste for certain flexible and rigid packaging.

-OYAK MERGED AKDENIZ KIMYA AND CHEMSON, AND BECAME THE LARGEST IN THE INDUSTRY

A US$ 500 million giant merger in the field of PVC stabilizers: OYAK merged Akdeniz Kimya and Chemson, and became the largest in the industry

OYAK has added a new one to its company merger moves focusing on efficiency and profitability. Following the merger of its companies in the cement and energy industries, OYAK merged Akdeniz Kimya, one of its companies operating in the chemical industry, and Chemson, an Austrian firm it acquired in 2013, under the name of “Akdeniz Chemson”. Thus, with its operations in five continents and sales to 110 countries, Akdeniz Chemson has reached a sales volume of US$ 500 million and has become the world’s largest company in the field of PVC stabilizers. Petrochemicals CrudeOil BOPP

OYAK General Manager Süleyman Savaş Erdem: “We consider the pandemic process as a ‘period of determination’ for OYAK.

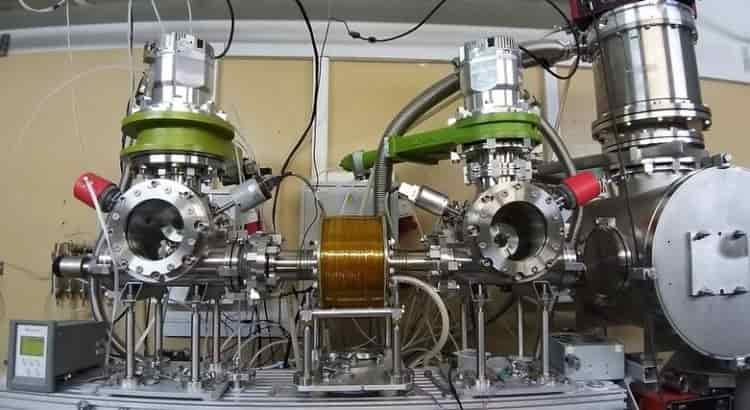

-Russia Develops New Wire Market Technology

The problem of gilding thin aluminum wires to obtain chemical resistance and the possibility of fixing (soldering wires) is very acute in the world.

The technology uses optical fibers glued into a matrix to transfer the light signal from scintillator crystals to the photodetector. Petrochemicals CrudeOil BOPP

According to the developers, tests of the sprayed optical fiber gave a positive result, the light transition was significantly suppressed.

Russian scientists have developed new technology geared at the wire market. In particle physics, an important task in creating detectors is to cover various plastic fibers and metal wires (with diameters of several tens of microns or more) with a thin layer of a given metal.

Kraton Corporation (KRA) this week shared its plans of expanding its production capacity for SBS polymer grades.

The specialty chemicals company is a leading global producer of high-value biobased products and specialty polymers. Petrochemicals CrudeOil BOPP

To remain in a leading position in sustainability in its core market, Kraton is aware of the need to reduce the carbon footprints for the environment as well as for its customers. This also includes putting efforts to increase efficiency of raw materials and utilization of materials that are bio-based. Kraton is currently focused on development of innovative novel SBS grades for bitumen modification to allow for significantly lower dosages, commented Dr. Holger Jung, Kraton’s Senior Vice President and President, Polymers. The company remained successful in lab demonstrations and is aggressively collaborating with customers to test the same in field.

-How waste CO2 is helping to turn renewable energy into liquid fuel

An adequate coordination could ensure waste products or byproducts from one process – such as CO2 – can be used as a raw material for another

Storing power generated by strong winds or bright sunshine by turning it into liquid fuel such as methanol can help to ensure green energy does not go to waste, without having to rely on batteries. Petrochemicals CrudeOil BOPP

Methanol can be made from CO2 captured from industrial sources, combined with hydrogen split out of water using surplus renewable energy. And the resulting fuel can be used in cars or ships, reducing the use of fossil fuels as well as emissions of greenhouse gases.

-DataLase launches functional masterbatch additive for plastics integration

Photonic printing solutions provider DataLase has developed a functional masterbatch additive suitable for a wide range of plastics, including home and personal care, pharmaceutical, medical, electronic, automotive, agricultural and industrial extruded products. Petrochemicals CrudeOil BOPP

By addressing the challenges faced by production and manufacturing companies with product coding applications, such as printing expiry dates and lot numbers, DataLase Masterbatch Additive has been optimised specifically for extrusion and injection plastic moulding to provide unsurpassed product stability and excellent quality.

Launched as a DataLase VAReLase Pigment Solutions initiative, the additive is integrated directly into the masterbatch in pellet form, to provide consistent high quality, high contrast, permanent black coding. When compared to other coding methods, the masterbatch additive works with standard CO2 scribing lasers to provide sustainability benefits in production environments by eliminating labels, consumables and waste from the coding and marking process. It can also help streamline supply chains through a reduction in packaging.

-The tech industry and recycling: The need-to-knows

The tech industry holds the trump card when it comes to innovation surrounding recycling —considering they are, in fact, the innovators.

As the world becomes more environmentally conscious and the EU sets targets to make all plastic packaging recyclable by 2030, businesses across the globe are looking for innovative ways to reduce their own waste through the production process and have a more circular economic approach. Petrochemicals CrudeOil BOPP

As the tech industry strives to become a role model for recycling, we discuss the approaches some tech companies have taken and the benefits of taking recycling seriously.

So, what’s new

The UK tech sector, in 2019, outpaced both that of the US and China in terms of growth. According to TechNation, it’s growing at a rate 2.6 times that of the overall economy. With this mind, the businesses within the sector have a role to play when it comes to limiting the carbon footprint. A report by the government noted that the digital sector alone contributes more than £400 million a day to the UK economy.

-Lummus wins technology contract for new PP plant at Lukoil refinery in Bulgaria

Lukoil is planning a 280,000-metric tons/year PP plant at its integrated refinery and petrochemicals facility at Burgas, Bulgaria, said Chemweek.

Lummus Technology has been awarded a contract by Lukoil (Moscow, Russia) to license its Novolen polypropylene (PP) process for a new 280,000-metric tons/year PP facility in Burgas, Bulgaria. The value of the contract and the timescale has not been disclosed.

The contract work scope for the proposed PP unit to be located at Lukoil subsidiary Lukoil Neftohim Burgas’ 180,000-bbl/d refining and petrochemical facility on the Balkan peninsula includes the technology license, as well as basic design engineering, training and services, and catalyst supply. It will be the first PP plant to use Novolen technology in southeast Europe, says Lummus. Lukoil first confirmed it was considering a new PP facility at Burgas in 2018. Petrochemicals CrudeOil BOPP

HYUNDI has brought a new meaning to the phrase ‘fast fashion’ by making clothes from discarded car parts including seatbelts and AIRBAGS.

The manufacturer has teamed up with several high-end fashion designers to upcycle the discarded materials from the automotive manufacturing and scrapping process – and sell them at Selfridges. Petrochemicals CrudeOil BOPP

The sustainable garments include jumpsuits made from upcycled denim and leather scraps, and a corset made of recycled airbag fabric.

There is also a Fuji Technical Vest created from discarded seatbelt webbings and airbag materials while a work vest with pockets was also made from the same product.

Petrochemicals CrudeOil BOPP