Petrochemicals Enzymes Aromatics News 30-05-2020 - Arhive

Petrochemicals Enzymes Aromatics News

-How is Rising Concerns Regarding Environment Driving Bio-Based PET Market?

The use of plastic is highly common in both general and industrial applications, owing to which, plastic has almost become an indispensable part of everyone’s daily lives.

Despite its extensive range of applications, the use of plastic needs to be minimized as it is causing severe harm to the environment.

One kg of plastic emits approximately six kg carbon dioxide, which has resulted in global warming.

Moreover, governments of several countries are imposing strict rules and regulations for decreasing greenhouse gas (GHG) emissions.

For example, France adopted the Energy Transition for Green Growth Law in 2015 for reducing GHG emissions and diversifying its energy supply by decreasing the use of nuclear and fossil fuels.

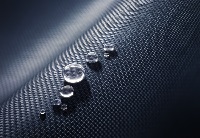

-The Role of Nanotechnology in the Production of Fabrics

Nanotechnology has recently brought immense improvement in the textile industry. The unique properties of nanomaterials are applied in an efficient manner by textile engineers and scientists, and it has gained enormous attention in the commercial market for their huge economic benefits.

Production of Specialized Fabrics Using Nanotechnology

Nanomaterials in textiles have proved to be immensely valuable for the manufacturing of protective garments for workers involved in emergency services such as military personnel, firefighters and medical workers.

There are different methods for the production of nanoengineered textiles. For example, sometimes synthesized nanoparticles are incorporated into the fibers or textiles.

-The next big fashion trend could be antiviral clothing

Antiviral products going, well, viral is nothing new. While slowly creeping back onto shelves, the nationwide shortage of hand sanitizers is still a recent memory (via New York Times). To protect ourselves from the novel coronavirus, we as a society will try just about anything. As we buy up sanitizers, wipes, and add face masks to our wardrobes, we continue the quest for extra protection. Next on that quest may be antiviral clothing.

Canadian inventor Giancarlo Beevis describes the inspiration: “As people start to go back to work and we try to restart our economy, they want to feel protected” (via Fast Company). Beevis’ vision for the textile market has been spurred forward by a partnership with Youngdo Kim, CEO of Okyung International, a Korean textile manufacturer, in what the partners hope will be a fast-tracked, emergency use claim that their product kills this coronavirus.

-Dow moves ahead with the RENUVA™ Mattress Recycling Program

Pioneering production facility will recycle end-of-life mattresses into raw material suitable for use in new polyurethane products

HORGEN, Switzerland, – Dow Polyurethanes (PU), a business division of Dow (NYSE: Dow), is proud to announce a breakthrough in its RENUVA™ Mattress Recycling Program with a plan to install a pioneering industrial scale production facility at Orrion Chemicals Orgaform in Semoy, France.

The RENUVA™ Mattress Recycling Program will take discarded mattress foam and turn it back into raw material (polyol) through chemical recycling, the process of converting waste into feedstock. The new raw material can then be used in flexible or rigid foam products to go into applications such as building insulation boards and even back into new mattresses.

Every year, around 30 million mattresses are thrown away in Europe. If they were all stacked up, the pile would be 678 times the height of Mount Everest1. This new initiative will help enable a more circular economy for polyurethanes by ensuring the applications they are used in can be recycled, and it can help the EU reach its goal of having 65% of municipal waste recycled by 2030.

-How does the world’s plastic waste get recycled? Or does it? And will recycling solve our problems?

The six very important questions about plastics recycling

Our relationship with plastics is changing fast. Recycling is key to replacing the material’s old linear life cycle with a circular one, prolonging its lifetime – but there is still confusion over many aspects of the recycling process.

Imagine a plastic bag blowing in the wind. It sweeps past your window, untangles itself from the branches of a tree and finally disappears from sight. Now imagine that bag was the last stray piece of plastic waste there ever was.

Plastic waste is a growing environmental concern for our generation but it doesn’t need to be a problem for the next. Besides an attitude change towards seeing all waste as a valuable material for new uses, plastics recycling is one of the key elements helping to solve the plastic waste crisis. But there is a lot of confusion about how plastics recycling process actually works. We asked experts to answer the big questions surrounding recycling to find out how close we are to solutions.

-The plastics industry is using COVID-19 to lobby against legislation of single-use plastic

Could the COVID-19 pandemic catalyse a loosening of environmental protections in the name of public health?

That’s the subtext of lobbying efforts from the Plastics Industry Association and petrochemicals giants in the US, which attempts to highlight the public health risks of restricting single-use, oil-based plastics. They may have their work cut out.

As a recent social sciences study from The University of Amsterdam and Avantium highlights, consumers are increasingly aware of the environmental impact of the things they buy, and prepared to pay a premium for sustainable products.

The pandemic’s effect on our travel and working behaviour have revealed the positive effects of reducing greenhouse emissions more than ever. The irony is that plant-based polymers and intermediates are if anything superior to the petroleum-based substances they replace.

A good example is PEF (polyethylene furanoate) – a plant-based alternative to PET. Unlike most petroleum-based plastics, PEF is 100% recyclable and has close to zero gas permeability. Moreover, it can be produced, processed and recycled in existing assets, making it an attractive product for producers, converters and recyclers.

-AIMPLAS targets dairy packaging odours

A method of using microorganisms to eliminate odours from dairy packaging is being developed by the Plastics Technology Centre (AIMPLAS) as part of its ongoing project to develop more sustainable processes.

The Enzplast2 project, named as such because it is in its second year, focuses on the use of enzymes for different applications.

Initial results from the AIMPLAS centre in Valencia, Spain, indicate a reduction in the odour intensity of recycled dairy packaging.

-How a circular economy approach can help protect the environment for future generations

Used PET bottles can play an important role in addressing the environmental impact of plastic

Lightweight and inexpensive, plastic is one of the world’s most used materials, but its extreme durability means that effective end-of-life management is critical. High quality recycling is therefore an indispensable solution for processing plastic waste.

Recycling considerably benefits the environment, as new goods are replaced by recycled goods. It reduces demand for raw resources, requires less energy for processing, and reduces the quantity of plastic in the landfill.

PET is the most recycled plastic because of its multiple advantages over other types of plastic. It is a very inert polymer, which makes PET packaging ideal for storing food, as it has virtually no interaction with the contents. It has the property of creating a barrier for oxygen and water and can be easily formed, and is highly resistant and very lightweight. Also, it can be used to produce transparent bottles, which is not possible with PE or PP.

-Coronavirus, oil price crash – impact on chemicals

Asian petrochemical shares fell along with crude oil on Friday on concerns over China’s decision to impose a new national security law on Hong Kong, which the US, UK, Canada and Australia deemed to be “in direct conflict with its international obligations”.

In the vinyl acetate monomer (VAM) market, northeast Asian producers have hiked offers to pass on firmer ethylene input costs to buyers, while demand remained weak and supply ample.

Economic data out of Asia continued to show strong hits from the measures implemented to contain the deadly novel coronavirus pandemic.

Petrochemicals Enzymes Aromatics News