Petrochemicals Enzymes Recycling 09-08-2021 - Arhive

Petrochemicals Enzymes Recycling

Petrochemicals MEG Polyethyleneterephthalate Trend

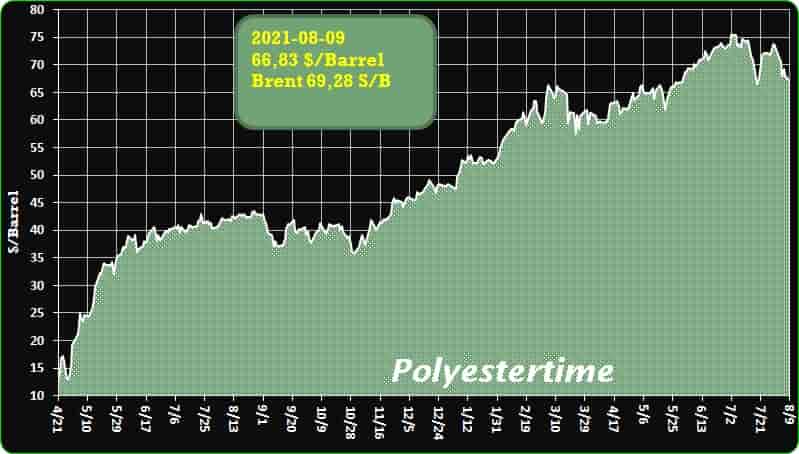

Crude Oil Prices Trend

-Indorama progresses toward 2025 goal to recycle 50 billion bottles annually

The company has mentioned the importance of recycling to its future growth.

Global chemical company and polyethylene terephthalate (PET) recycler Indorama Ventures Public Co. Ltd. (IVL), headquartered in Bangkok, has announced its second-quarter 2021 financial results, reporting record core earnings before interest, taxes, depreciation and amortization (EBITDA) of $477 million. This is a 30 percent quarter-over-quarter increase. The company says it is forecasting similar growth in the second half of 2021 and in 2022 as global vaccination programs spur positive sentiment.

“During the pandemic we doubled down on our transformation and development programs as we build towards a future-ready organization, and we are now starting to see the results of these initiatives as global vaccination programs spur a recovery,” Aloke Lohia, group CEO, says. “We will continue to benefit from the economic tailwinds as all three of our business segments—Combined PET, Fibers and Integrated Oxides & Derivatives (IOD)—experience strong demand and margins. Petrochemicals Enzymes Recycling

-Waste-to-virgin plastics company Nexus Fuels pursuing global expansion

Cushman & Wakefield has announced that the commercial real estate services firm has been retained by Nexus Fuels, an Atlanta-based waste to virgin plastics company, for site selection services across the globe as part of their expansion plans.

JT Faircloth and John Jackson of Cushman & Wakefield will oversee initial national site selection process which will likely lead to other parts of the world where Nexus sites are being evaluated. Petrochemicals Enzymes Recycling

“Site selection is an important part of the process to economically convert previously landfill bound plastics into new plastics which Nexus does along with their global partners,” Faircloth said. “Proximity to labor, ports, rail, and plastics feedstock all weigh heavily in the decision-making process. We are excited to work with Nexus Fuels on this important expansion initiative to improve the environment.”

The company plans to purchase or lease 12 locations or more by first quarter of 2022 in the United States, Europe and other parts of the world which Nexus customers are seeking. Nexus plans to be operational at these locations by 2023.

-China’s export slowdown in July may signal more bumps ahead

- July exports +19.3% yr/yr vs +20.8% forecast in Reuters poll

- July imports +28.1% yr/yr vs +33.0% forecast

- July trade balance $56.58 bln vs $51.54 bln forecast

China’s export growth unexpectedly slowed in July following outbreaks of COVID-19 cases, while imports also lost momentum, pointing to a slowdown in the country’s industrial sector in the second half even as easing global lockdowns boost commerce.

The world’s biggest exporter has staged an impressive economic rebound from a coronavirus-induced slump in the first few months of last year after quickly containing the pandemic, and its rapid vaccination rollout has helped drive confidence. Petrochemicals Enzymes Recycling

But new infections in July, mainly caused by the highly transmissible Delta strain have spread to tens of Chinese cities, prompting local authorities to lock down affected communities, order millions to be tested and temporarily suspend operations of some businesses, including factories.

-Technip proprietary burner technology can now be potentially used in avoiding direct CO2 emissions

Technip Energies announced the successful test of its Large Scale Vortex Burner (LSV) for 100% firing of hydrogen, according to Hydrocarbonprocessing.

The innovative LSV burner was developed by Air Products and designed and applied by Technip Energies’ in various fired heater usages. The successful test demonstrates the potential use of LSV in avoiding direct CO2 emissions by substituting 100% hydrogen for methane or other fuel gases. Petrochemicals Enzymes Recycling

The LSV® burner is a cost-effective, low-NOx combustion solution. This technology has been applied successfully over the past 15 years in cracking furnace and hydrogen reformer installations, in both new or retrofitted projects. The burner can now be applied to different process heating applications and combustion air supply modes and also is suitable for a wide range of fuel gas compositions and firing configurations.

-SABIC now marketing chemically recycled polycarbonate

Global petrochemical company adds polycarbonate resins and blends to its TruCircle product line.

Saudi Arabia-based SABIC is now offering what it calls a certified circular polycarbonate (PC) resin, saying it is the first such resin in the industry based on advanced or chemical recycling. Petrochemicals Enzymes Recycling

The company says its “certified circular” polycarbonate (PC) resin and blends are “made from the upcycling of post-consumer mixed plastic – a first in the industry.” The recycled-content PC will be marketed as part of SABIC’s TruCircle product line.

Adds SABIC, “This solution, based on advanced recycling, demonstrates SABIC’s ongoing commitment to drive toward a circular economy for plastics by increasing the availability of more sustainable products.”

According to an internal SABIC life cycle analysis study, the new PC resin offers a potential carbon footprint reduction up to 23 percent “in comparison with its incumbent.”

States Abdullah S. Al-Otaibi, a general manager with SABIC, “We are proud to have developed a new solution that can help our customers to meet their sustainability targets and generate value by increasing the amount of recycled post-consumer mixed plastic they process.”

-Potential of enzymes for PET waste recycling

A more sustainable approach for recycling PET polyester may be to use enzymes.

This is the theory of researchers from the US Department of Energy’s (DOE’s) National Renewable Energy Laboratory (NREL) and the UK’s University of Portsmouth.

They are part of a consortium called BOTTLE – Bio-Optimised Technologies to keep Thermoplastics out of Landfills and the Environment.

BOTTLE is striving to address the problem of plastic pollution via two approaches:

To develop energy-efficient, cost-effective, and scalable recycling and upcycling technologies. Petrochemicals Enzymes Recycling

To design modern plastics to be recyclable by design.

The consortium’s new research paper addresses the challenge of plastic recyclability. While images of discarded bottles floating in oceans and other waterways provide a visual reminder of the problems posed by plastic waste, the lesser-considered issue remains what to do with the PET used to manufacture textiles for clothing and fibres for carpet.

The researchers have modelled a conceptual recycling facility that would take in a fraction of the three million metric tons of PET consumed annually in the United States.

-Growing solutions to plastic problems – Ohio Ag Net

Plastic is around us. Cookware and tableware, toys and games, car and truck fenders, syringes, fence posts, disposable water bottles, signs, and even human anatomical parts made with 3D printers. They are all made of plastic.

We are grateful to Leo Baekeland, a wonderful but eccentric Belgian-born chemist, for taking us into the world of plastics. He experimented with formaldehyde and phenolic formulations and invented the first type of plastic in 1907, named Bakelite. It is a sturdy heat-resistant product that can be molded into various shapes, and was mainly used in electrical equipment such as telephones.

Baekeland landed on the cover of his history-making invention time magazine. And with the founding of the first plastic company, Bakelite, he became known as the father of the plastics industry. Tagline for his company’s star products: “Thousands of Materials Used”. Petrochemicals Enzymes Recycling

Bakelite has focused on innovations in mobile phones, smartwatches, robotics and more today. Since his breakthrough, new chemical compositions have been developed to further expand the use of plastics. Too many to be included in this publication.

-Caprolactam price underpinned by low operating rate in short

Benzene contract and spot prices have been declining continuously since late July. Following that, Sinopec has also cut down the contract nomination for CPL, but the decrease is narrower than feedstock benzene. After a narrow fall in late July, spot CPL market has rebounded slightly in end-July to early August. These indicate the fact that CPL market is still in a tight balance right now.

Downstream nylon 6 polymer plants have been suffering heavy pressure, and the operating rate (especially in conventional spinning chip plants) has dropped to almost the lowest rate in history. Petrochemicals Enzymes Recycling

Comparing CPL and polymer plants’ operating rate (O/R), the average CPL plant O/R has pegged around 75-80%, while that of polymer plants lingers around 65%. Consider their capacity differential, CPL supply is still not enough.

It is particularly the case as the imports in the first half of the year are low, when imports in June drop to 7kt only. Restricted China domestic production and the short in imports have contributed to current tightly supplied CPL market

-Starlite and Supervent come together for greener bottles

French company Competek is providing Sidel’s Starlite base solution together with its own Supervent technology, in order to allow OEMs to produce greener bottles without changing the entire production line or modifying bottle design.

Created by the collaboration between PET Engineering and COMEP, Competek’s service allows for the production of a lightweight bottle with a saving of up to 1g for 500ml, and 2g for a 1.5-litre bottle. Petrochemicals Enzymes Recycling

Available for both flat and carbonated products, Sidel’s Starlite helps reduce the weight of the bottle by increasing the bottle’s resistance and stability once palletised.

Competek’s Supervent uses a system of vents to improve the release of air, therefore reducing the pressure required for blow moulding and ensuring energy savings. It is also compatible with 100 per cent recycled materials.

Petrochemicals Enzymes Recycling