Petrochemicals Film HDPE Recycling 03-09-2021 - Arhive

Petrochemicals Film HDPE Recycling

Crude Oil Prices Trend

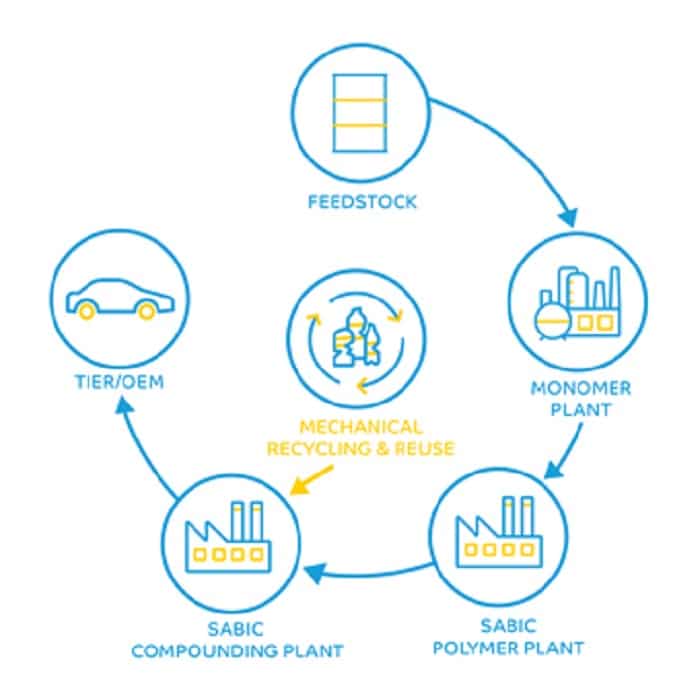

-SABIC launches recycled automotive grades under TRUCIRCLE portfolio of circular solutions

SABIC introduced the company’s first automotive grades containing mechanically recycled content within the company’s TRUCIRCLE portfolio of circular solutions and services. The new resins are SABIC T2E-3320EH PP compound, a high-flow, low-emission, talc-filled polypropylene (PP); XENOY T2NX2500UV resin, an unfilled, UV-stabilized blend of polycarbonate (PC) and polyethylene terephthalate (PET); and XENOY T2NX5230 resin, a mineral-filled PC/PET blend.

All three materials contain up to 29% recycled content and offer excellent performance similar to that of the incumbent virgin resins, giving automotive customers new options that can help them address their sustainability goals.

The new TRUCIRCLE materials support the automotive industry’s sustainability initiatives by providing an opportunity to extend the life of plastic waste and helping to increase value from post-consumer products. These new products are the first of many SABIC resins to be introduced with mechanically recycled content for potential use in interior and exterior automotive applications. They also may complement other types of sustainable materials, such as certified renewable products from bio-based content, which we are also developing. It’s all part of SABIC’s strategy to accelerate towards a true circular economy.

-BMW announces sustainability strategy and CO2 targets

The group is focusing its research and development efforts on environmentally-compatible raw materials and boosting the creation of a secondary materials market.

BMW Group chairman Oliver Zipse announced a sustainability strategy and CO2 targets at a media event in Munich.

The main focus is to “drastically” reduce CO2 per vehicle by 2030.

The group will be promoting the use of secondary material and the circular (recycling) economy.

The group is focusing its research and development efforts on environmentally-compatible raw materials and boosting the creation of a secondary materials market by working with startups and experienced material suppliers to develop pioneering materials. Petrochemicals Film HDPE Recycling

“We are setting new standards for sustainable premium quality by rethinking materials and focusing on resource-efficient alternatives and renewable materials with strong dismantling capability,” said BMW executive Stefan Floeck.

The group has defined material groups with sustainable properties which span all four dimensions of the circular economy: RE:THINK, RE:DUCE, RE:USE and RE:CYCLE.

-Indorama Ventures delayed R-PET project in Philippines due to the pandemic

Indorama Ventures (IVL’s) joint venture with Coca-Cola Beverages Philippines (CCBPI) to start a recycled polyethylene terephthalate (R-PET) plant in the Philippines has been delayed primarily due to the pandemic, said the company.

IVL and CCBPI entered into a joint venture agreement in March 2020 to launch an R-PET facility in Cavite, Philippines with target opening date by end 2021. The plant will have the capacity to process 30,000 tonnes/year of PET bottles and produce around 16,000 tonnes/year of R-PET pellet. Petrochemicals Film HDPE Recycling

However, due to the logistical challenges posted by COVID-19, the plant’s launch has been delayed to March 2022.

IVL entered into the agreement with CCBPI through its indirect subsidiary Indorama Ventures Packaging (Philippines) Corp (IVPPC) which will give the company a 70% ownership, with the remaining 30% owned by CCBPI.

According to MRC’s ScanPlast report, Russia’s estimated PET consumption totalled 411,200 tonnes in the first six month of 2021, up by 12% year on year. Russian companies processed 62,910 tonnes in June, compared to 85,890 tonnes a month earlier.

-Weekly Resin Report: The Calm Before the Storm

Prices for most commodity-grade polyethylene and polypropylene continued a slow slide last week. Then came Hurricane Ida.

The spot resin markets stayed in the slow lane as the end of August approached, but with Hurricane Ida barreling through the gulf this weekend, the situation could quickly change, reports the PlasticsExchange in its Market Update. Prices for the vast majority of commodity-grade polyethylene (PE) and polypropylene (PP) materials continued to slowly slide, peeling off pennies of the previously large premiums held to contracts, which rose again his month.

Overall resin supplies, including prompt availability for most PE and PP materials, continued to improve. Spot demand became lackluster, well off the pace seen during the first two quarters of the year. Petrochemicals Film HDPE Recycling

While some producers continued to operate under force majeure conditions, most contract buyers have been receiving the full allocation of their forecasted orders. Some processors who had over forecasted, thinking only 75% might be supplied, had extra resin to sell when producers shipped their complete orders.

August PE contracts probably will settle flat after securing a $0.05/lb increase in July — high-density (HD) PE for blow molding and injection, which remained relatively tightly supplied, were reasonably justified, said the PlasticsExchange, while low-density (LD) PE and linear-low-density (LLD) PE film grades, which have become generally accessible, seemed to just come along for the ride.

-Joint research project of Krones and Alpla delivers surprising results

Despite attractive environmental credentials, returnable PET containers remain a niche product.

Krones and Alpla are cooperating on a research project aimed at better realizing this packaging type’s potential.

The result is a returnable PET container specially designed for chilled juices and dairy products. Petrochemicals Film HDPE Recycling

Objective tests provide informati n about microbiological safety.

Rising out of the niche: In the beverage packaging market, returnable PET containers currently play a rather small role. Wrongly so, say the results of a joint research project of Krones and Alpla. In the project’s first phase, the material and process parameters underwent a comprehensive scientific evaluation. Based on these findings, Krones and Alpla developed a returnable PET container that provides an optimal environment for sensitive ESL (Extended Shelf Life) products such as juice and milk in the cold chain.

Be it due to regulations, voluntary climate targets, or growing environmental awareness among consumers, sustainability issues are becoming an increasingly important factor in packaging choice. “Which type of packaging performs best from an ecological perspective depends on a number of factors and must be evaluated individually for each use case,” explains Martina Birk, who is responsible for the enviro sustainability programme at Krones.

-Green alternatives to single-use plastic

Consumers are demanding more sustainable solutions, and some are even willing to pay a premium for products delivering on sustainability claims.

In 2021, the E.U., several U.S. states, and other countries including Canada pledged to ban single-use plastics and poly-fluoroalkyl substances (PFAS) or ‘forever chemicals’ that are added to food packaging, and for good reason. An alarming 380 million tons of plastic are produced every year and the COVID-19 pandemic only made things worse. It’s estimated that the use of single-use plastics soared by 250 to 300 per cent worldwide during COVID-19. Petrochemicals Film HDPE Recycling

The food packaging industry is at a crossroads. Nearly 40 per cent of plastic used across the world comes from packaging, and often this waste is not recyclable. In fact, it’s estimated that less than 10 per cent of plastic has been recycled since 1950. In the near future, eco-friendly packaging will be a necessity.

Green packaging alternatives

Moulded fibre or pulp is a green alternative that is made from 100 per cent recycled paper or natural fibres. This alternative is a cost effective and eco-friendly packaging solution. It can be compostable unless it gets lined with plastic.

-Soteria acquires nano-aramid tech

Soteria Battery Innovation Group, headquartered in Greenville, South Carolina, has acquired intellectual property from Elegus Technologies to improve the battery cycle life and safety of electric vehicles.

Soteria’s Dreamweaver nonwoven battery separators use aramid fibres for increased thermal and chemical stability, preventing the separator from melting or shrinking in the presence of a defect or damage. Petrochemicals Film HDPE Recycling

With the growing adoption of electric powertrains in both vehicles and aircraft comes a desire for longer cycle life from the expensive battery pack.

Lithium-ion cells generate both moisture and hydrofluoric acid as they age, which degrade the cells over time.

Elegus Technologies, formed as a spinout of the University of Michigan, has developed technology utilising nano-aramid fibres that enables the separator to immobilise these harmful elements in the cell, reducing the rate of degradation and extending the life of the cell.

-Asian recyclers of film grade HDPE operate at low rates due to COVID-19

Recyclers in Southeast Asia were heard operating with low capacity utilisation in the film grade high density polyethylene (HDPE) market due to COVID-19-led lockdown measures, reported S&P Global.

Market sources also said persistent bottlenecks at ports in Asia and some maintenance-related plant closures are likely to hurt the supply of petrochemicals during the week of Aug. 30-Sept. 3. Petrochemicals Film HDPE Recycling

As MRC informed earlier, Southeast Asian polyethylene terephthalate (PET) recycling companies will continue facing challenges with the availability of raw materials, due to the low collecting and processing rate, as a result of the COVID-19 pandemic.

-Legislative Proposals Could Destroy US Plastics Industry, Cautions Paper

The first of a four-part series of papers from libertarian think tank Competitive Enterprise Institute explains how plastics, in fact, benefit wildlife and the environment.

Several proposals before Congress that nominally want to end America’s “addiction” to plastics in reality are so extreme they could destroy the US plastics industry.

That is the position of the Competitive Enterprise Institute (CEI), a Washington, DC–based non-profit libertarian think tank, and it aims to set the record straight with a series of four in-depth, science-based papers. The first of those is published today, a 14-page piece detailing how plastics benefit wildlife and the environment. The other three papers will address the value that plastics bring to humanity, environmental facts and fallacies, and why legislation before Congress will not solve real problems related to litter. Petrochemicals Film HDPE Recycling

The paper published today and authored by Angela Logomasini, PhD, a senior fellow at CEI, covers terrain familiar to most plastics professionals but it can serve as an eye-opening educational resource for the general public. It begins with a very readable description of how plastics are made before delving into why they were made in the first place, which may be a revelation to some.

-German site EuCertPlast certified for recycling film waste

The recycling plant of German plastics recycler APK (Merseburg; www.apk-ag.de) in Merseburg has been certified according to the “EuCertPlast” standard since the end of July 2021, the company has announced. Carried out by certifier Cyclos-HTP (Aachen / Germany; www.cyclos-htp.de), the focus of the audit was the suitability of the facilities for recycling post-consumer waste from plastic films and production waste from PE/PA multilayer films. Petrochemicals Film HDPE Recycling

APK uses a solvent-based process called “newcycling”, which makes it possible to recycle multilayer plastic packaging with different polymers, said Florian Riedl, the director for business development. The plant is said to have conventional recycling process’ input capacity of 12,000 t/y and 8,000 t/y for the newcycling process. LDPE recyclates produced at the plant are sold under the brand name “Mersalen” and PA recyclates under “Mersamid”.

Petrochemicals Film HDPE Recycling