Petrochemicals Graphene CarbonFiber PA 25-07-2020 - Arhive

Petrochemicals Graphene CarbonFiber PA

Greener credentials, manufacturing and ‘pawprints’ were among the many brand owner announcements during the past month as sustainable ambitions and targets came under the spotlight.

Kimberly-Clark launched new packaging as part of its Andrex Greener Paw Print initiative, which uses 30 per cent recycled plastics from post-consumer resin.

Beauty brand L’Oréal, meanwhile, is aiming to eliminate non-recycled plastics packaging by 2030, technology firm HP plans to reduce single-use plastics packaging across its portfolio by 75 per cent by 2025, and two divisions of Dole Asia have outlined plans to move towards zero fossil-based plastics packaging by 2025.

-Eliminating the impact of intentionally added microplastics

Sean Smith (pictured) is the CEO of Eden Research plc, an AIM-quoted company focused on sustainable biopesticides and plastic-free encapsulation technology for use in the global crop protection, animal health and consumer product industries.

We are hearing more and more about microplastics infiltrating the environment. In some contexts, plastics have been considered a more sustainable option than natural resources, however it is now evident that plastic pollution is a significant global problem. Nature simply does not have the tools to effectively break many of these materials down in the environment. Petrochemicals Graphene CarbonFiber PA

-Oil Prices and the Fate of Bioplastics in the Marketplace

Bioplastics can be costly to produce and can only compete on price with fossil-based plastics if oil prices are high, and they aren’t.

Polymer prices have always been tied to their raw material costs, such as oil and natural gas. Falling prices for both of these constituent materials has correspondingly resulted in reduced prices for virgin plastics. The industry has experienced this carnival ride over the past few decades, and demand for recycled materials reluctantly has been along for the ride. Petrochemicals Graphene CarbonFiber PA

Ten or so years ago, virgin PET was cheaper than recycled PET (rPET) because of the costs to collect, sort, and re-process the recyclate. Packaging companies complained to me at various trade shows that commitments to higher recycled content in their packaging were becoming hard to keep. It was also pushing their prices higher. Consumers are willing to pay a bit more for products in recycled-content packaging, but there are limits.

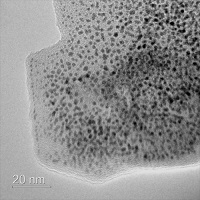

-New graphene material for longer-lasting fuel cells

Researchers from Queen Mary University of London and University College London (UCL) have produced graphene via a special, scalable technique and used it to develop hydrogen fuel cell catalysts. In an open-access paper published in the RSC journal Nanoscale, the researchers report that this new type of graphene-based catalyst was more durable than commercially available catalysts and matched their performance.

Platinum is the most widely used catalyst for fuel cells, but its high cost is a big problem for the commercialization. Petrochemicals Graphene CarbonFiber PA

To address this issue, commercial catalysts are typically made by decorating tiny nanoparticles of platinum onto a cheaper carbon support—however the poor durability of the material greatly reduces the lifetime of current fuel cells.

-Recent Innovations For Staple & Man-Made Fiber Spinning

With Savio’s Industry 4.0 technologies — such as the Savio Winder 4.0 data management system and the Savio Smart Bracelet — connectivity, data management, remote machine set-up and real-time operator interactivity are possible.

Spinning technology introductions make efficient, cost-effective and high-quality yarn production more attainable than ever before. Petrochemicals Graphene CarbonFiber PA

Spinning technology is a more mature segment in the textile machinery industry. Beginning with Eli Whitney’s cotton gin in 1794, and after several centuries of revolutionary ideas and rapid technology advances, the modern-day spinning plant now is highly automated and technologically advanced. New technology introductions to the space tend to offer incremental improvements rather than earth-shattering innovations.

-A Circular Economy In The Plastic Sector Is Possible, Here’s How

The world is going through a plastic pollution crisis that is affecting not only the environment but the health of humans and all animals as well. From burning plastic causing severe health problems in people to marine creatures turning up dead and birds being found with bellies full of plastic, the situation is critical. In Europe alone, 60 million tons of plastics are produced, but only 30% of them are recycled. Worldwide, 79% of all the plastic waste that’s been generated has ended up as litter in the natural environment or a landfill like a stain on the planet. Petrochemicals Graphene CarbonFiber PA

People are starting to become more aware of the problems caused by plastic, and societies are planning out how to transition to a more circular economy where materials, like plastics, are reused at the end of their life. For this, new recycling technologies will play an important role.

-Why traceability matters in recycling and the circular economy

Global total waste is on course to grow 70% by 2050, while each human being creates an average of 500kg of waste per year. Nonetheless, we are only recycling around 20% of our global plastic waste.

We need new systems to motivate the significant behavioural changes required to make change. It is imperative that new mechanisms be established to ensure ongoing value is derived from our waste. Petrochemicals Graphene CarbonFiber PA

Digital traceability: object history, distribution, location and application

-Chemical Recycling is Essential to Achieve EU’s Circular Economy Goals: Cefic

The European Chemical Industry Council (Cefic) supports the chemical recycling technology and believes that it is important for the technology to stay part of the EU’s innovation agenda in order to create a more dynamic market for recycled plastic.

Today, just 15 % of EU-collected plastic waste in the EU finds its way back into the EU plastic market. Chemical recycling can treat waste that can’t be recycled mechanically, and therefore plays an important role in the mix of solutions to tackle the problem of plastic waste. Mixed or contaminated plastic waste is currently burned in an incinerator, ends up in a landfill or litters our streets and waterways. Chemical recycling is the only technology available today that can change this. Petrochemicals Graphene CarbonFiber PA

-Oil prices fall on U.S. inventory build, increasing pandemic fears

In his first briefing in months focused on the pandemic, U.S. President Donald Trump said that the outbreak would probably get worse before it gets better, one of his first recent acknowledgements of the spread of the problem

Oil prices fell on Wednesday as industry data showed a bigger- than-expected inventory build in the United States where coronavirus cases continue to climb, potentially further denting demand in the world’s biggest oil consumer. Petrochemicals Graphene CarbonFiber PA

In his first briefing in months focused on the pandemic, U.S. President Donald Trump said that the outbreak would probably get worse before it gets better, one of his first recent acknowledgements of the spread of the problem.

-Daimler’s savings target puts 20,000 jobs at risk, report says

Daimler’s plans to make deeper cost cuts than planned before the global pandemic could translate to the elimination of about 20,000 jobs, according to people familiar with the matter. Petrochemicals Graphene CarbonFiber PA

The Mercedes-Benz maker has boosted its labor-cost savings target to 2 billion euros ($2.3 billion) from 1.4 billion euros, said the people, who asked not to be identified because talks with union representatives are still ongoing. The final number of job cuts will be determined by different factors, including acceptance rates of voluntary buyouts and efforts to outsource some IT services.

Petrochemicals Graphene CarbonFiber PA