Petrochemicals Oil prices Trend 04-10-2021 - Arhive

Petrochemicals Oil prices Trend

Petrochemicals Polyamides Polyester Trend

Crude Oil Prices Trend

-Oil prices may hit $100 this winter, spurring economic crisis, warns Bank of America

The global energy crunch could help propel oil prices above $100 a barrel for the first time since 2014 and spur a global economic crisis, according to Bank of America.

Natural gas prices have already surged to almost double that level in oil equivalent terms, and BofA says a spike in demand for diesel could push crude into similar territory. With monetary and fiscal policy stretched to the limit and energy costs rising as a share of economic output, higher oil prices could in turn create a macro crisis, the bank said Friday in a note.

The boost to crude would be driven by three factors: gas-to-oil switching as a result of high gas prices, a jump in crude consumption over a cold winter and higher aviation demand as the U.S. reopens its borders.

“If all these factors come together, oil prices could spike and lead to a second round of inflationary pressures around the world,” analysts including Francisco Blanch wrote in the note. “Put differently, we may just be one storm away from the next macro hurricane.”

Diesel prices could climb above $120 a barrel, the bank said, with stockpiles falling as refiners prioritized the production of gasoline in recent months. Other oil-based fuels used in heating are already seeing an uplift, with U.S. propane prices at their highest since 2014.

-Alpla purchases BTB PET-Recycling

The acquisition gives Alpla access to bottle-to-bottle recycling loop in Germany.

Austria-based Alpla Group says it is acquiring BTB PET-Recycling, Bad Salzuflen, Germany, in an investment designed to further develop the region’s bottle-to-bottle recycling loop. BTB processes used polyethylene terephthalate (PET) beverage bottles sourced from Germany’s reverse-vending system into food-grade rPET (recycled PET) pellets that are primarily used to make new preforms for PET bottles, including beverage bottles.

First, BTB presorts, shreds and washes the input material, which is then sorted again prior to melting and pelletizing, resulting in food-grade rPET. The company’s processing volume is roughly 20,000 metric tons, or 22,000 short tons, of PET bottles annually, Alpla says. BTB employs approximately 35 people, all of whom Alpla says it will retain.

Georg Lässer, head of corporate recycling at Alpla, says, “BTB produces highly efficiently using established technology. The team in Bad Salzuflen is highly motivated and does a fantastic job. For us, buying this company is an investment in the future, enabling us to increase the existing capacities and further strengthen the bottle-to-bottle loop.”

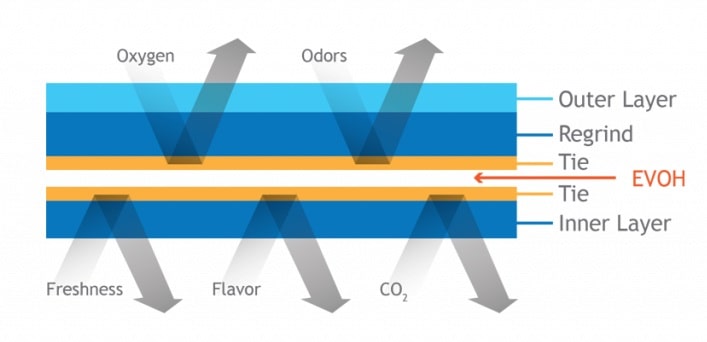

-Packaging producers seeing better plastic availability, EVOH still tight

Producers of plastic packaging commented that supplies of many of the commodity resins used to produce packaging are slowly improving after several months of tightness while adding that the market is currently facing difficulties obtaining adequate supplies of ethylene vinyl alcohol (EVOH), based on conversations with attendees at this year’s PACK EXPO, which was held on 27-29 September at the Las Vegas Convention Center.

EVOH is frequently used as an oxygen barrier in plastic films used in food packaging, helping to extended the shelf life of products covered by the films. EVOH supplies have tightened in response to persistent supply tightness in feedstock vinyl acetate monomer (VAM), supplies for which have faced lingering issues since Winter Storm Uri.

Packaging producers have been investigating EVOH-free film products, as monopolymer polyethylene (PE) films are more recyclable than films which include an EVOH layer between PE layers. However, EVOH resins remain popular as oxygen barriers given the advantages provided in extending the shelf life of foods and minimising food waste.

-Innovate with Plant-based Performance Fabric

Globally, there is a shift in consumer support toward conscious brands that have commitments to equitable workplaces, sustainable fabric choices, and intersectional environmentalism.

According to Edited, a leading retail market analysis group, sustainable activewear for menswear increased 65% year-over-year (2019-2020), while womenswear is up 45% in the category. Soon, this segment will make up the majority of the buying public for any season and garment type.

Going hand-in-hand with the need for sustainable fibers and fabrics is the need for transparency. In a survey from McKinsey & Co, “Sustainability and Transparency” was ranked #1 by over half of all executive respondents as the priority for sourcing at scale.

“Even before the pandemic, we an increased demand for traceability and transparency throughout the value chain,” says Global Brand & Communications Leader Alexa Raab. “We introduced our Common Thread Fabric Certification at the start of Q2 2020 to reduce haziness in the supply chain and work with mill partners to create certified fabrics that have a minimum amount of bio-based content and meet strict performance requirements.”

-Enzymes could help humanity win the war on plastic pollution

Plastics are one of the biggest and most problematic contributors to pollution. Millions of tons of plastic end up in the ocean each year. According to environmentalist Ellen MacArthur, if plastic production and pollution continue at the current rate, by 2050 the ocean will contain more plastic by weight than it does fish. Part of what makes plastic so problematic is that it’s not biodegradable and can take up to hundreds of years to break down in nature. Most plastic ends up either in landfills or in the ocean. It is estimated that less than 10% of plastic is actually recycled. In the decades since plastic usage has become widespread, it’s proven unruly and unsustainable. However, in the last few years scientists have discovered an enzyme that has the potential to transform our relationship with plastic forever.

Polyethylene terephthalate, or PET plastic, has been one of the dominant types of plastic since it was patented in 1941.

-Dr. Bio: A biopolymer made from starch to tackle the single-use plastic menace in India

A Gurugram based company becomes the first in the country to manufacture a plant-based biopolymer.

This year 5 trillion plastic bags will be used. That’s 160,000 a second!

If you line them up one after the other, they will go around the world 7 times every hour and will cover an area twice the size of France. Don’t get too shocked yet, as we have only mentioned plastic bags so far and there’s more to the plastic menace than you can imagine.

Consider this: a global study points out that 79 per cent of the total plastics manufactured globally enter our environment as waste. While out of this, merely 9 per cent is recycled. Let’s now talk about us.

India’s contribution in plastic waste generation is humungous—3.3 million metric tonnes per year. Even this can be an underestimated figure, and its only growing. After taking its harmful effects into cognizance, it becomes apparent that plastic waste is a formidable environmental challenge which can’t be ignored for long.

While there are several ongoing worldwide initiatives that have been undertaken to tackle this problem, biopolymers have emerged as one of the sustainable and greener ways to replace single-use plastics.

-A New Solid-state Battery Surprises the Researchers Who Created it

Engineers created a new type of battery that weaves two promising battery sub-fields into a single battery. The battery uses both a solid state electrolyte and an all-silicon anode, making it a silicon all-solid-state battery. The initial rounds of tests show that the new battery is safe, long lasting, and energy dense. It holds promise for a wide range of applications from grid storage to electric vehicles.

The battery technology is described in the Sept. 24, 2021 issue of the journal Science. University of California San Diego nanoengineers led the research, in collaboration with researchers at LG Energy Solution.

Silicon anodes are famous for their energy density, which is 10 times greater than the graphite anodes most often used in today’s commercial lithium ion batteries. On the other hand, silicon anodes are infamous for how they expand and contract as the battery charges and discharges, and for how they degrade with liquid electrolytes. These challenges have kept all-silicon anodes out of commercial lithium ion batteries despite the tantalizing energy density. The new work published in Science provides a promising path forward for all-silicon-anodes, thanks to the right electrolyte.

-Will spandex price plunge with weaker demand?

Spandex prices continued surging in recent one year and current price has hit the highest level since 2008. Recently, export orders did not chase up smoothly and domestic demand was soft. Some dealers started revising down price. Will spandex price plunge later? Does market fundamentals of spandex change?

There will be above 110kt/year of new spandex capacity to be launched in the second half of 2021 in Chinese mainland and it may bring about 30kt of production increase according to the startup time. By Sep 26, the operating rate of spandex plants declined to 93% from 97% in end-Aug. The control of total amount and the intensity of energy consumption is expected to affect spandex supply in short run. Some spandex plants scaled down production by around 10-40%. Xiamen Lilong suspended production due to the pandemic, affecting near 2% of spandex operation rate. Most old spandex units are still expected to run at above 90% of capacity and new units will gradually start operation. Spandex production is anticipated to gradually ascend in Q4.

-EC-funded PyroCO2 project gets underway

A project designed to support the European Green Deal – the plan to make the EU’s economy sustainable and climate-neutral by 2050 – has kicked off, involving a consortium of 20 industrial and research partners from 11 countries.

The aim of the European Commission-funded project – called PyroCO2 – is to demonstrate a new path to create value from industrial carbon dioxide emissions while improving the sustainability of the chemical industry in Europe. The €40 million ($46m) funding (part of a total €44m budget) will be used to showcase large-scale conversion of emissions into value-added chemicals and materials.

A 5-year project, the consortium will build and operate a facility capable of capturing 10,000 tonnes of industrial carbon dioxide per year, and use it to produce chemicals.

“We are excited to finally start our ambitious work that aims to be a game-changer for European carbon-intensive industries,” said Alexander Wentzel, senior research scientist at SINTEF, the independent Norwegian research institute that coordinates the project.