Petrochemicals PET Film Recycling 01-09-2021 - Arhive

Petrochemicals PET Film Recycling

Crude Oil Prices Trend

Made from recycled material and designed for recycling: Starlinger viscotec, a division of the Austrian machinery supplier Starlinger & Co GmbH, has developed a new material to make packaging for dairy and hot-fill products fully recyclable. rPET100 combines the environmental advantages of recycled PET with easy material processability and opens opportunities for new circular packaging solutions.

Food packaging for applications like dairy, hot drinks, instant soups, and ready-meals must withstand higher temperatures during the production process and consumption. Additionally, dairy products require packaging with optimal light and gas barrier for longer shelf life. The new rPET100 sheet combines these benefits and adds new ones: it is heat resistant, made from monomaterial, and its white colour protects the product from UV light. Once used, the packaging can be 100% recycled because it contains no other polymer additives.

Trays, cups, and food containers made from rPET100 are the fully recyclable alternative to singleuse cups made from materials like polypropylene (PP) or polystyrene (PS). Post-consumer recycled PET fulfils all requirements of the European Food Safety Agency (efsa) when it has been supercleaned with Starlinger viscotec technology. PET/rPET has outstanding material properties that can be restored in the recycling process, which makes PET a truly circular packaging material.

-Circular economy at Kelheim Fibres

Examples of innovation from raw material, product design and all the way to “end of life”

A sustainable product is a mosaic of many individual building blocks – Kelheim Fibres, the world’s first viscose fibre producer with an EMAS-certified environmental management system, is constantly working to further improve every single one of these building blocks. Petrochemicals PET Film Recycling

The innovative viscose special fibres from Kelheim can be functionalised as required – this often saves further processing steps (such as dyeing or coating) and thus also energy, water and chemicals. At the end of their product life, fibres from Kelheim are completely biodegradable in a short time (according to OECD Test 301 B) and thus contribute to the preservation of valuable habitats.

Now Kelheim Fibres is taking a step further: the fibre specialists are working on the development of alternative raw materials, such as recycled cellulose as well as other cellulosic feedstocks for the production of their viscose fibres. One approach to closing the product loop in the textile sector is the use of pulp produced from recycled post-consumer waste materials.

Kelheim Fibres offers its customers innovative viscose fibres made exclusively from certified wood from sustainably managed forests for the production of plastic-free and biodegradable end products.

-Klöckner Pentaplast breaks new ground with recyclable PET blister film

Klöckner Pentaplast (KP) has launched kpNext – a recyclable PET blister film that the company says is the only PET recyclable blister that is “completely compatible” on pharmaceutical manufacturing form, fill and seal equipment.

According to KP, pharmaceutical companies and converters can utilise kpNext on their existing form, fill and seal lines with no loss of line speed or a need to retool.

In terms of end-of-life, the solution is produced from a globally recyclable material and is designed to be recycled in the RIC (resin identification code) #1 PET stream.

Daniel Stagnaro, head of technology stated: “Current pharmaceutical blister packaging is classified as RIC #7, produced from a multi material structure, which is not recyclable and therefore is disposed in a landfill or incinerated.

Petrochemicals PET Film Recycling

Kolon Industries, a chemical and textile manufacturing company in South Korea, will produce recycled polyethylene terephthalate (PET) chips for various applications with eco-friendly and high-quality raw materials from Gr3n, a Swiss company that invented an innovative process to chemically PET bottles and food containers.

Gr3n’s technology is based on the application of microwave technology to alkaline hydrolysis, which provides an economically viable recycling process of PET.

Kolon Industries said it has signed a memorandum of understanding with the Swiss company to establish a business partnership for chemical recycling technology.

The two companies would mass-produce eco-friendly plastics from 2025 and expand cooperation in various forms in eco-friendly materials. Petrochemicals PET Film Recycling

“We are very happy to have the opportunity to collaborate with a global partner who has core capabilities and competitiveness needed for eco-friendly renewable plastic businesses,” Kolong Industries CEO Jang Hui-goo said in a statement on August 30.

-Thin-wall injection compression moulding for stack mould technology

ENGEL’s stand at Fakuma 2021 from 12-16 October in Friedrichshafen, Germany, will put the spotlight on sustainability. The production of decorated monomaterial food packaging and the processing of regrind from labelling waste is supporting circular economy by creating a process chain.

At the same time, the company is celebrating the world première of the 4,200 kN version of the ENGEL e-speed injection moulding machine. The sophisticated packaging application combines extreme thin-wall injection compression moulding with stack mould technology. Petrochemicals PET Film Recycling

Over the five days of the trade event, an e-speed 420/90 injection moulding machine with integrated in-mould labelling (IML) will be used to produce ready-to-use margarine tubs from polypropylene in a fully automated injection compression process. The containers, which have a wall thickness of 0.4 mm (including the label), will be removed from the 4+4-cavity stack mould via high-speed, side-entry automation and stacked on a discharge conveyor following camera-based quality control. Corporate partners at the trade show will be MCC Verstraete, Plastisud, Campetella, Mevisco and Borealis.

-Flexible Packaging, the One to Dethrone Plastics and Glass

We’re all very aware of the negative impact that plastics, specifically plastic packaging, have in our life, but let’s look at the numbers again, shall we? Around 91 percent of plastic packaging ends up in landfills, oceans, or elsewhere in our environment, secreting harmful chemicals each day. According to the International Union for Conservation of Nature (IUCN), an estimated eight million tons of plastic ends up in oceans each year, wreaking havoc on ecosystems, the food chain, and human health. Petrochemicals PET Film Recycling

“Let’s migrate to glass bottles, then” is a common conclusion in the thought process after acknowledging the harm of plastic.

The thing is, making glass –and shipping it– has a very high carbon footprint. Let’s take the case of wine making, for example. The Australian Wine Research Institute (AWRI) estimates that glass bottle production and shipping makes up for 51 percent to 68 percent of wine’s total carbon footprint. Yes, glass is a pretty good material, especially for beverages because of how well it preserves them, but it needs incredibly high heat to be made, and tons of fuel and plastic packaging to be shipped in order to prevent any cracks.

-Sateri sets the benchmark in China

All of the five viscose mills of Sateri in China are now fully compliant with the emission limits set out in the European Union EU-BAT BREF (best available techniques reference document) on polymers, following recent verification of Sateri Jiangsu and Sateri China mills.

Verified by independent consultant Sustainable Textile Solutions (STS), a division of BluWin in the UK, the parameters assessed included resource utility efficiency, wastewater discharge and air emissions. Petrochemicals PET Film Recycling

“Sateri Jiangsu was established in 2019 following an acquisition, while Sateri China was built in the same year,” said company president Allen Zhang. “We had aimed to have both mills meet EU-BAT’s recommended emission levels by 2023. To achieve this two years ahead of schedule underscores our continuous efforts in process improvement and the control of pollutant emissions, along with resource utilisation efficiency. We will continue to pursue manufacturing excellence and invest in best-in-class technologies for all our mills – existing, acquired, and newly constructed ones – as part of our commitment towards closed-loop and cleaner production.”

-Incredible Fibers Produced by Engineered Bacteria: Stronger Than Steel, Tougher Than Kevlar

Artificially designed, amyloid-silk hybrid protein developed in Zhang lab even outperforms some spider silks.

Spider silk is said to be one of the strongest, toughest materials on the Earth. Now engineers at Washington University in St. Louis have designed amyloid silk hybrid proteins and produced them in engineered bacteria. The resulting fibers are stronger and tougher than some natural spider silks. Petrochemicals PET Film Recycling

Their research was published in the journal ACS Nano.

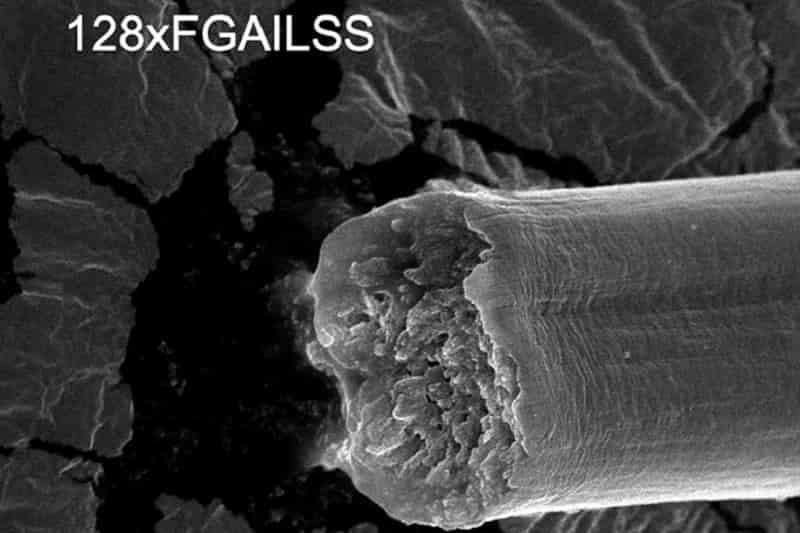

Spun Polymeric Amyloid Fiber

The 128-repeat proteins resulted in a fiber with gigapascal strength which is stronger than common steel. The fibers’ toughness is higher than Kevlar and all previous recombinant silk fibers. Its strength and toughness are even higher than some reported natural spider silk fibers. Credit: Washington University in St. Louis/Jingyao Li

To be precise, the artificial silk — dubbed “polymeric amyloid” fiber — was not technically produced by researchers, but by bacteria that were genetically engineered in the lab of Fuzhong Zhang, a professor in the Department of Energy, Environmental & Chemical Engineering in the McKelvey School of Engineering.

SenseTime, which has applied to arrange an estimated US$2 billion stock sale in Hong Kong, said its artificial intelligence (AI) platform may be used to power the smart-driving, intelligent cockpit and autonomous driving features in as many as 20 million cars in the next several years. Petrochemicals PET Film Recycling

The Hong Kong-based AI company, founded by a group of professors at the Chinese University of Hong Kong (CUHK), has formed partnerships with 30 carmakers, including Japan’s Honda Motors, and China’s Great Wall Motors and Chery Automobile, said SenseTime’s co-founder and managing director of its research laboratory Wang Xiaogang.

“There is a huge business potential for us to tap in this area,” Wang said in an interview with South China Morning Post before filing their application to list in Hong Kong, citing the combined production of the customers who have signed up for SenseTime’s technology. “The vehicle will become the third major space where people spend the most amount of time, after their homes and their offices.”

-Recyclers pursue PV module scheme in Brazil

Recycling firm SunR has processed 30 tonnes of discarded solar panels since launching its recycling services in Brazil at the start of the year. The company expects to receive another 125 tonnes by the end of the year. Petrochemicals PET Film Recycling

SunR has recently received more than 100 disposal requests from all over Brazil, representing a demand of approximately 300 tonnes. The recycler has told PV Magazine that although most of these solar panels have been installed in the last five years, there is already considerable demand for recycling. This is mainly due to damage occurring during transport or maintenance. Solar farm operators are wary of strict rules and want to ensure their PV modules pass the necessary quality tests.

Leonardo Gasparini, ceo of SunR, estimates that the 9 GW of installed capacity in Brazil (which translates to roughly 500 000 tonnes of panels) have thus far generated around 40 000 tonnes of end-of-life materials. The entrepreneur puts the market value of the material at some US$ 20 million (EUR 17 million).

‘One of the main problems in Brazil is inadequate disposal, not the options for recycling,’ Gasparini explains. He observes that recycling is a more adequate and cheaper solution than landfilling or incineration. ‘The biggest challenge, however, is the logistics,’ he insists.

Petrochemicals PET Film Recycling