Petrochemicals PET GreenHydrogen 06-04-2021 - Arhive

Petrochemicals PET GreenHydrogen

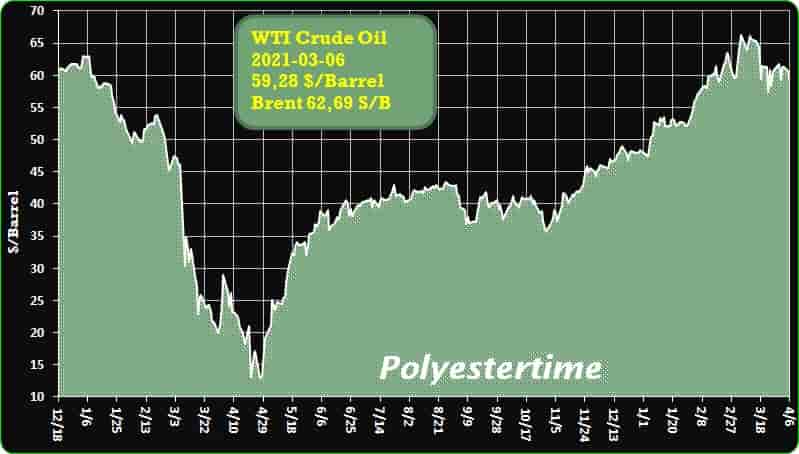

Crude Oil Prices Trend

-NPP “POLYPLASTIC” has been audited by three car manufacturers

NPP POLYPLASTIC, the largest Russian manufacturer of thermoplastic composite materials, has been audited by three leading car manufacturers, the company said.

In the first quarter of this year, the company received the results of audits based on the supplier assessment standards of the Renault-Nissan-Mitsubishi Alliance, Magna International and Faurecia.

ASES completed with an increase in the ranking, audits by Magna International and Faurecia confirmed the existing rather high ranking of NPP “POLYPLASTIC”. “The audits have confirmed that the company is able to ensure the production of high-quality raw materials and nominate its materials for new projects, while the requirements of the automotive industry in terms of physical and mechanical properties, rheology and specific characteristics of materials are growing every year,” comments Ekaterina Smirnova, Deputy Sales Director of Torgovy at home “Polyplastic”, an authorized commission agent of NPP “POLYPLASTIC”.

-Xi’s Gambit: China plans for a world without US technology

Anticipating efforts by the Biden administration to continue to challenge China’s technological rise, the country’s leaders are accelerating plans to go it alone, seeking to address vulnerabilities in the country’s economy that could thwart its ambitions in a wide range of industries, from smartphones to jet engines.

China is freeing up tens of billions of dollars for its tech industry to borrow. It is cataloging the sectors where the United States or others could cut off access to crucial technologies. And when its leaders released their most important economic plans last week, they laid out their ambitions to become an innovation superpower beholden to none. Petrochemicals PET GreenHydrogen

Anticipating efforts by the Biden administration to continue to challenge China’s technological rise, the country’s leaders are accelerating plans to go it alone, seeking to address vulnerabilities in the country’s economy that could thwart its ambitions in a wide range of industries, from smartphones to jet engines.

-April contract prices of phenol in Europe rose by EUR305 per tonne

European April contract prices for phenol rose to record highs to EUR 1,829-1,859 per tonne, up EUR305 per tonne from the previous month, ICIS reported .

The market remains very tense amid high demand in the downstream segment, higher raw material prices, lack of imports and preparations for the second quarter.

ICIS Phenol Contract Valuation, like many commercial contracts, is based on changes in benzene production costs and a surcharge that changes quarterly.

The contract prices for benzene feedstock in April rose by EUR230 per tonne, and the increase was carried over to the phenol market. As a result, the phenol contract reached a record high for April. Petrochemicals PET GreenHydrogen

Previouslyit was reported that the contract price of phenol in Europe in March rose by EUR163 per tonne after the increase in prices for benzene feedstock. Thus, the March prices of phenol were agreed at the level of EUR1 524-1 554 per tonne, FD NWE (North-Western Europe) after an increase by EUR163 per tonne of March contracts for benzene. Phenol contract price declined last month, the first drop in three months, reflecting a change in benzene feedstock contracts.

-PLASTIC POLLUTION: HOW CAN CHEMICAL RECYCLING TECHNOLOGY HELP FIX THIS GLOBAL ISSUE?

Plastics are here to stay and production expected to exceed one billion tonnes by 2050, chemical recycling is promising. Petrochemicals PET GreenHydrogen

It’s impossible to imagine everyday life without plastics. Lightweight, durable and cheap, these materials outperform many others in a diverse range of applications

Plastics have brought about positive change in ways we often overlook. For example, the development of plastic components in electronic devices, such as the one you’re using to read this article, means we’ve never been more connected to the world around us.

But our love of plastics has come at an environmental cost. It’s been estimated that of the 8.3 billion tonnes of plastic made between 1950 to 2015, over 75 percent is now waste, with 79 percent accumulating in either landfill or the natural environment.

-AIMPLAS enters financial year with €13.3 million revenue and sustainability commitment

AIMPLAS closed 2019 with a 14% increase in revenue based on 226 R&D&I projects, became leading plastics technology center in Valencia, constructed new facility that promote research for circular economy. Petrochemicals PET GreenHydrogen

Back in October 2020, AIMPLAS (Valencia, Spain) Plastics Technology Centre, closed the 2019 financial year with revenue of €13.3 million ($15.66 million), which represents a 14% increase compared to the previous year. Its commitment to social and environmental sustainability was also highlighted by a report verified by the Global Reporting Initiative (GRI), an independent organization that is a pioneer in report presentation and an international benchmark in sustainability reports. AIMPLAS also notes the construction that also began in 2019 on a new 1,500-square-meter building which plays a role in environmental sustainability.

-Lummus Technology will provide technologies for the NKNKh olefin complex

Nizhnekamskneftekhim (NKNH, part of TAIF Group) has signed contracts with Lummus Technology LLC for the provision of licenses and technologies for the production of ethylbenzene, styrene and propylene for the olefin complex, the company said. Petrochemicals PET GreenHydrogen

Facilities include a 250 ktpa ethylbenzene and styrene unit using EBOne and CLASSIC SM technologies, and a 150 ktpa olefin metathesis unit for polymer-grade propylene using Lummus’ ethylene dimerization and olefin conversion technology Technology. The units will operate as part of the olefin complex under construction (EP-600).

The contract was signed on March 31 by the general director of Nizhnekamskneftekhim (part of the TAIF group) Ayrat Safin and the vice president and managing director of the ethylene and petrochemical department of Lummus Technology, Stephen Stanley.

Earlier it was reported that the main stage of construction of the Ethylene-600 olefin complex should be completed in December 2022, which will allow the start of production in the second half of 2023.

The complex plans to annually produce 600 thousand tons of ethylene, as well as 272 thousand tons of propylene, 246 thousand tons of benzene, 88 thousand tons of butadiene.

The LYCRA Company, a global leader in fiber and textile solutions for the apparel industry, is pleased to announce the launch of its first performance offerings made from 100% textile waste. COOLMAX® and THERMOLITE® EcoMade fibers made from textile waste are the result of a strategic collaboration between The LYCRA Company and ITOCHU Corporation, a general trading company with strength in consumer-related sectors, including the textile business.

The new offerings pair the brand equity and performance attributes of these leading cooling and warming brands with the sustainability benefits of textile waste, thus helping address a critical industry need. Petrochemicals PET GreenHydrogen

“We are pleased to announce our alliance with ITOCHU in helping to address textile waste, which represents a substantial sustainability challenge as the equivalent of one garbage truck of textiles is sent to landfills or incinerated every second1,” said Julien Born, chief commercial officer for The LYCRA Company.

“This collaboration exemplifies the synergistic approach we have to develop products and technologies that support a more sustainable future for our vast global customer base.” This is the first of several innovations that The LYCRA Company is working on in textile and garment recycling. Laying the groundwork for a more circular future is one of the key objectives of The LYCRA Company’s Planet Agenda Sustainability platform.

-Eneos sets April contract price for benzene in Asia at USD835 per tonne

Eneos (formerly JXTG Nippon Oil & Energy), part of Eneos Holding, a major petrochemical producer in Japan, set its April contract price for benzene in Asia at USD835 per tonne, down USD20 per tonne compared to the March contract price, a company source told ICIS . Petrochemicals PET GreenHydrogen

The price was approved on CFR Asia delivery terms.

Meanwhile, the company nominated its April contract price for material at USD865 per tonne, which is USD10 per tonne higher than the contract price in March.

The March contract price of benzene in Asia was set at USD855 per ton, which isUSD195 per tonne is higher compared to the February contract price .

Benzene is a raw material for the production of styrene, which, in turn, is the main raw material for the production of polystyrene (PS).

-Trinseo and BASF Jointly Announce Business Collaboration on Circular Feedstock

Trinseo and BASF announce today the intention to expand their businesses with the production of styrene based on circular feedstock

Trinseo and BASF Jointly Announce Business Collaboration on Circular Feedstock

Trinseo and BASF announce today the intention to expand their businesses with the production of styrene based on circular feedstock . Petrochemicals PET GreenHydrogen

- Partnership based on shared values supporting circularity with styrenic plastics;

- Biomass-balanced feedstock: Distinct greenhouse gas reduction with product properties unchanged;

- Chemically recycled feedstock: Plastic waste redirected into production cycles.

The enhanced collaboration between Trinseo and BASF aims to increase efforts by both companies in the development and management of styrene featuring an improved environmental profile.

Trinseo has recently been procuring first supplies of the synthetical chemical styrene based on circular feedstock from BASF for use in its Solution-Styrene Butadiene Rubber (S-SBR) and polystyrene (PS) products. Trinseo supplies S-SBR to major tires manufacturers while its PS products are used in applications such as food packaging and appliances. The first few customers have already processed the material.

-Science: New bioplastic degrades entirely in three months

A new durable synthetic material offered by researchers from Yale University. The material called bioplastic can degrade entirely in three months, Springwise reports.

The simple manufacturing process generates biomass-based plastics from the wood powder typically found at lumber mills. Petrochemicals PET GreenHydrogen

While the world is continuing its fight against the novel pathogen, researchers are inventing brand new biodegradable material. Scientists offer more eco-friendly forms of plastic, using materials such as eggshells, plants, and even tequila waste.

To turn the wood powder into a slurry of organic polymers and cellulose, the chemists use a biodegradable solvent with another two steps, hydrogen bonding and entanglement at a nanoscale level.

Petrochemicals PET GreenHydrogen