Petrochemicals PET Sorting Recycling 07-09-2019 - Arhive

Petrochemicals PET Sorting Recycling

-DiloGroup On Display At Techtextil India

DiloGroup, consisting of DiloSpinnbau, DiloTemafa, DiloMachines and DiloSystems, offers production machinery for complete processes to make needled staple fibre nonwovens, from fibre preparation, to carding, crosslapping or aerodynamic webforming, needlepunching or other consolidation technologies for any fibre material.

In its 117 year history, the company has always set new standards in regard to machine performance and efficiency. Innovative technologies like DI-LOUR, DI-LOOP and Hyperpunch have created new markets for the nonwovens industry and have contributed to continuous growth. Petrochemicals PET Sorting Recycling

-FPG units report disappointing sales

ABOMINABLE AUGUST:Formosa Plastics Group’s four major companies saw revenue decline mainly due to weak product prices, sluggish demand and plant maintenance

Formosa Plastics Group’s (FPG, 台塑集團) four major units reported disappointing sales for last month, as product prices dropped further amid languid demand.

Formosa Chemicals & Fibre Corp (FCFC, 台灣化學纖維), which manufactures integrated plastic and nylon products, saw sales decline 28.62 percent annually and 5.36 percent monthly to NT$25.99 billion (US$831.5 million), as its major products’ prices declined by more than US$200 per tonne compared with a year earlier, company vice chairman Hong Fu-yuan (洪福源) told a media briefing in Taipei.

-Plastics recycling technology roundup: Sept. 6, 2019

Plastics Recycling Update iconDow is recognized for a polyurethane foam chemical recycling technology, and a project testing invisible packaging markers to improve optical sorting wraps up. Petrochemicals PET Sorting Recycling

Mattress foam recovery: Dow won an award for its technology to break down polyurethane foam from end-of-life mattresses into polyols. Optimized over the past year, the process creates what Dow is branding “RENUVA” polyols. They can be tailored for applications such as flexible foam or rigid foam for construction application. “Replacement of up to 25 percent of the virgin polyol in conventional flexible foam recipes was achieved without deterioration of the foam physical properties,” according to a press release. The technology received a sustainability award from Business Intelligence Group.

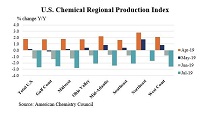

-U.S. Chemical Production Fell In July

According to the American Chemistry Council (ACC), the U.S. Chemical Production Regional Index (U.S. CPRI) fell by 0.9 percent in July following revised declines of 0.8 percent in June and 0.6 percent in May. During July, chemical output was lower in all regions, with the largest declines in the Mid-Atlantic, Northeast and West Coast regions.

Chemical production was mixed over the three-month period. There were gains in the production three-month moving average (3MMA) output trend in chlor-alkali and other inorganic chemicals. These gains were offset by declines in the output of pesticides, synthetic rubber, coatings, fertilizers, consumer products, plastic resins, organic chemicals, synthetic dyes & pigments, adhesives, manufactured fibers, and other specialty chemicals.

-Report recaps plastic bumper cover recycling project

Challenges remain to scaling up TPO bumper collection to a national scale. | Kaentian Street/Shutterstock

TPO bumper covers can be processed into a high-quality recycled pellet that’s cheaper than virgin plastic, but challenges remain in feedstock collection and preparation.

That’s a conclusion from a Plastics Industry Association report recapping the multi-year End-of-Life Vehicle (ELV) Recycling project, which examined recycling potential for thermoplastic polyolefin (TPO) bumper covers. Petrochemicals PET Sorting Recycling

-Biodegradable plastic: A false promise?

Biodegradable packaging is often pitched as the environmentally-friendly solution the world has been waiting for.

However, so-called greener plastics don’t necessarily break down as easily as marketers would have us believe.

To make matters worse, biodegradable plastic can’t be recycled. So if it doesn’t readily disappear into nature and can’t be reused, should we consider the “biodegradable” label a well-intentioned but misleading promise? The Down to Earth team investigates.

-German industrial output slumps again in July, heighteningrecession fears

German industrial output fellagain in July, slumping 0.6% month on month,according to data agency Destatis, leaving theodds of the country falling into recession “allbut confirmed”, according to an analyst.

The July fall was largely driven by a 1.3%month on month drop in energy production, aswell as contractions in intermediate andcapital goods output, offsetting increases inconsumer goods and construction.

Output also fell 1.1% in June, fuelling concernthat one of the key engines of the eurozonewill be shown to have fallen into recessionduring the quarter.

-Sabic promotes optical resins for LiDAR components

Sabic will participate in the Technology Showcase at Automotive LIDAR 2019, to be held in Dearborn, MI, from Sept. 25-26.

Aurélie Schoemann, Sabic business manager, Mobility, will give a technical presentation on high-performance optical resins for mobility on Sept. 25, beginning at 4:20p.m, at the Henry Hotel.

Schoemann will explore key challenges affecting the design, manufacture and performance of LiDAR sensors and explain how optical thermoplastic resins such as Sabic’s Ultem amorphous polyetherimide (PEI) can provide solutions.

In particular, she will focus on infrared (IR)-transparent resins for optical LiDAR components.