Petrochemicals PETBottle Biopolymers 12-04-2021 - Arhive

Petrochemicals PETBottle Biopolymers

Petrochemicals Naphtha PolyesterDTY Trend

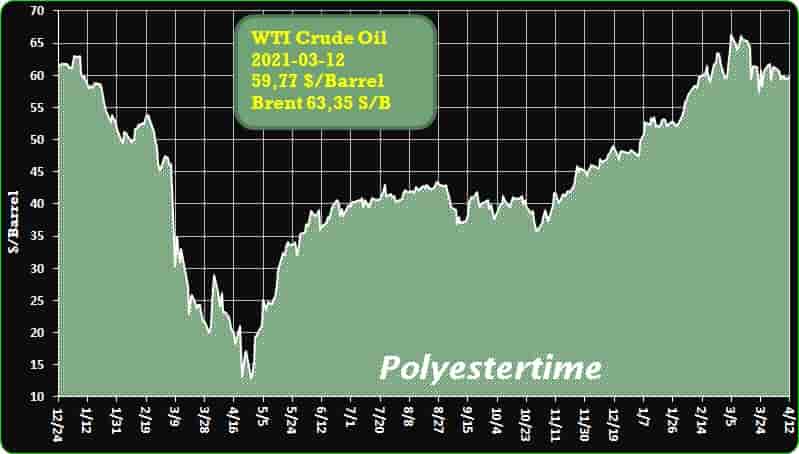

Crude Oil Prices Trend

-Saudi wants OPEC+ to extend oil cuts into June, source says

After steady oil price gains earlier this year, OPEC and its allies, known as OPEC+, had hoped to ease output cuts

Saudi Arabia is prepared to support extending oil cuts by OPEC and its allies into June and is also ready to prolong its own voluntary cuts to boost prices amid a new wave of coronavirus lockdowns, a source briefed on the matter said on Monday.

After steady oil price gains earlier this year, OPEC and its allies, known as OPEC+, had hoped to ease output cuts. Petrochemicals PETBottle Biopolymers

But a fresh wave of lockdowns to prevent a new surge in the virus has pushed oil off this year’s highs, and four OPEC+ sources told Reuters this would most likely encourage the group to extend cuts into May when it meets on Thursday.

-Groundbreaking inauguration of recycling plant in Indonesia

Coca-Cola Amatil Indonesia (Amatil Indonesia) and Dynapack Asia announced the construction of a 20,000 square meter Polyethylene Terephthalate (PET) recycling facility located in Bekasi, West Java. The newest investment valued at AUD 50.51 million (IDR 556.2 billion) will enable the collaboration of Amatil Indonesia and Dynapack Asia to create a closed loop plastic packaging supply chain by producing food and beverage safe plastic pellets made from post-consumer plastic bottles.

During the groundbreaking ceremony, Amatil Indonesia dan Dynapack Asia introduced PT Petrochemicals PETBottle Biopolymers

Amandina Bumi Nusantara and Mahija Parahita Nusantara with roles as:

- PT Amandina Bumi Nusantara – the entity which will run that state-of-the-art rPET facility leading the transformation process of low-quality PET waste back to virgin-quality, food-grade PET using the latest renewable technology;

- Mahija Parahita Nusantara – the non – profit foundation which will support collection centers management, ensuring the fulfillment of human rights and regulation in the waste collection supply chain, execute activities to improve the welfare of waste pickers and communities, as well as conducting research and development on recyclability improvement and other opportunities related to PET utilization and plastic collection.

-Plants: Americhem opens US compounding facility

Americhem opens US compounding facility

US compounding firm Americhem recently opened its new plant expansion dedicated solely to clean compounding for medical device customers in Morrisville, PA.

This Americhem Engineered Compounds, or AEC, plant expansion includes the addition of an isolated 20,000 sq. ft. “Clean Compounding” room that will house six new compounding lines in the overall 60,000 sq ft expansion. The new clean environment and AEC Customer Design Center, coupled with Americhem’s existing ISO 13485 Certification, gives AEC unique capabilities to produce compounds that meet the most stringent medical device requirements. Petrochemicals PETBottle Biopolymers

“Our medical compounding process is performed in our GMP production area, which ensures that all of our medical grade polymers and compounds will be made to the highest quality standards. It is designed to minimize contamination due to airborne contaminant and other contamination, while producing compounds in a clean, well-lit environment,” states Jim Figaniak, VP & GM of Americhem Engineered Compounds.

-Enviroo receives planning permission for first plant

Specialist PET (polyethylene terephthalate) recycler, Enviroo has had its planning application approved for its first plastic recycling facility in the UK. The facility will be able to re-use 100% of the PET it takes in and help recycle some of the 4.9 million tonnes of plastic waste created in the UK annually. Petrochemicals PETBottle Biopolymers

The successful application means the plastic recycling facility will be operational in Summer 2022 at Peel NRE’s 54-hectare strategic energy and resource hub, Protos, near Ellesmere Port, Cheshire. The facility will take PET – the main material used for food and drinks packaging such as plastic bottles and certain food packaging – and convert it into the raw material for new food-grade packaging. It will see an investment of around £20 million into the local economy and create 50 new, permanent jobs.

Enviroo will use proven technology to sort and wash the waste, before creating r-PET (recycled -PET) pellets that can be used by packaging manufacturers to create new packaging products. This technology is able to re-use 100% of the PET it takes in. This will become increasingly important from this time next year, when a new law will see any packaging that contains less than 30% recycled PET taxed. Some manufacturers have gone further, pledging to include up to 50% recycled material in their packaging under the UK Plastics Pact. The facility will therefore help to meet growing UK demand for recycled PET.

-Food Containers Made Of Seaweed Aim To Replace Plastic And Reduce Pollution

Highlights

What’s unique about these takeout containers is that it’s completely biodegradable and compostable, unlike conventional takeout containers which not only have plastic lining to prevent it from getting drenched. Petrochemicals PETBottle Biopolymers

The use of seaweed enables Notpla’s implementation to be grease and water-resistant while also being naturally biodegradable.

To encourage the use of biodegradable takeout containers, UK’s takeout food app Just-Eat has run a campaign where it is testing these containers by Notpla across UK’s popular food chains

The takeout food delivery app is hoping this could prevent as many as 30,000 plastic coated containers from entering the waste this long weekend. Food Containers Made Of Seaweed Aim To Replace Plastic And Reduce Pollution

Takeout food trash amounts to nearly half of all municipal solid waste in the US, according to the US Environmental Protection Agency (EPA).

In 2014 alone, out of the 258 million tons of municipal solid waste generated in the US, over 63 percent was of packaging materials out of which only 35 percent (amounting to around 89 million tons) was recycled or composted.

-Bio-based polymers and active coatings support greener food packaging

Inexpensive, fossil fuel-based coated plastics keep foods fresher and safer for consumption, but their detrimental impact on the environment may outweigh their benefits. EU-funded research has advanced bio-based alternatives leveraging microorganisms and natural metabolites. Petrochemicals PETBottle Biopolymers

Multilayer polymer food packaging is the industry standard, enabling multiple, necessary functionalities not present in any one alone. However, the multiple bonded layers that act as a barrier to oxygen and moisture are difficult to recycle, and the synthetic plastics are not biodegradable, creating a growing end-of-life problem.

Environmental concerns are shared by governments, industries and consumers, but finding recyclable and/or biodegradable monolayer alternatives with the same performance as conventional packaging has been quite challenging. With funding from the Bio-based Industries Joint Undertaking, a public-private partnership between the EU and industry, the ambitious REFUCOAT project brought together 12 multidisciplinary partners all along the value chain from 5 EU countries to address the problem.

REFUCOAT advanced the potential of two promising biodegradable biopolymers and also pushed the boundaries of what might be possible, demonstrating the use of bacteria-‘eating’ organisms (bacteriophages) in active coatings.

-Will U.S. Shale Trigger Another Oil Price Crash?

A year after the pandemic and the disagreement within OPEC+ over supply management crushed oil prices, the industry finds itself at an all-too-familiar crossroads: Will OPEC’s bet that U.S. shale’s “drill, baby, drill” is gone forever be right this time? Petrochemicals PETBottle Biopolymers

Analysts seem to concur that this is a safe bet, at least for this year, as U.S. shale overall will keep the promised spending discipline.

In a sign that spending beyond cash flows is a thing of the past, major listed producers now say that growing production for growth’s sake would be a big mistake. Instead, they have vowed to return more cash to shareholders.

U.S. oil production may never return to the weekly peaks of 13 million barrels per day (bpd) just before last year’s market crash.

But it is already steadying at around 11 million bpd, which is 1 million bpd above the May 2020 lows when producers curtailed output in response to impossibly low—and negative for a day—oil prices.

-How plastic pollution threatens our health, food systems, and civilization itself

Plastic pollution is so pervasive that plants are uptaking microplastics through their roots Petrochemicals PETBottle Biopolymers

One of the most memorable quotes from the classic 1967 film “The Graduate” turned out to be prophetic, too.

McGuire, a would-be mentor advising a young man about his future, was correct about the growth of the plastics industry, although perhaps not in the way he intended. Indeed, we have overproduced plastic on Earth, to the extent that it is clogging our oceans and waterways, squirreling itself into our food and fisheries, and poisoning our bodies. Climate change is often billed as the greatest existential threat to humanity — yet plastic pollution is equally horrific in its capacity to disrupt civilization.

Plastics are a relatively recent invention. When we think of “plastics,” what we’re really think of are synthetic polymers. Polymers are substances made from long chains of molecules — they can be found in nature, such as the cellulose in plants — and synthetic polymers are generally designed to be durable and flexible; hence why they are known as “plastic.”

-Hufschmied virtual masterclass demonstrates machining of carbon fiber winglet

Masterclass details how to efficiently manufacture demanding components from high-performance materials with a PPS CFRP winglet as an example.

Hufschmied Zerspanungssysteme GmbH’s (Bobingen, Germany) virtual masterclass, “Machining Thermoplastic Carbon Winglet,” held on Feb. 23, 2021, demonstrated the machining of a composite winglet carried out by CNC machine manufacturer Fehlmann AG Maschinenfabrik (Seon, Switzerland) and Ensinger Composites Schweiz GmbH (Otelfingen). Now, the demonstration video is available in English.

According to Hufschmied, in order to efficiently manufacture demanding components from high-performance materials, the machine, machining strategy and tool must be coordinated. Petrochemicals PETBottle Biopolymers

During the masterclass, Hufschmied, Ensinger and Fehlmann machined a carbon fiber-reinforced polyphenylene sulfide (PPS) TECATEC PPS CW50 PL winglet with complex free-form contours. The component was machined with Hufschmied’s Graftor tools, 065SMC drill milling cutter and FB162 drill on Fehlmann’s VERSA 645 linear five-axis high-performance milling center.

Petrochemicals PETBottle Biopolymers