Petrochemicals PETBottle USRussiaTension 21-04-2021 - Arhive

Petrochemicals PETBottle USRussiaTension

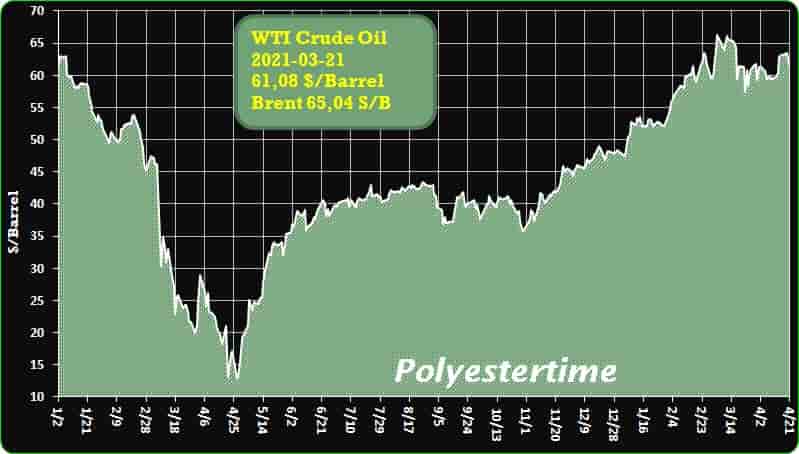

Crude Oil Prices Trend

-BASF announces force majeure for PA 6 shipments from Antwerp plant

BASF (Ludwigshafen), the world’s petrochemical major, will keep in place a force majeure (FM) declared on low-viscosity nylon-6 manufactured at its production site in Antwerp, Belgium, until further notice, reported Kunststoffweb with reference to a spokesperson.

After a fire in the production plant for PA 6 in Antwerp/Belgium, BASF has declared force majeure. Deliveries of the polyamide 6 types “Ultramid B24”, “Ultramid B27” and qualities with low viscosity are affected, a spokeswoman said when asked.

The fire occurred in a reactor building in the early evening of March 26, 2021 and was quickly extinguished, the spokeswoman said.

There were no environmental impacts for the neighborhood and no injuries. The repair work was already underway. However, the duration of the FM cannot yet be estimated. The force majeure affects the already limited availability of PA 6.

Nylon-6 is used in the production of compounds for automotive parts, electrical and electronics components, and in the manufacturing process of industrial goods, appliances and consumer goods.

-Solvay and Origin Materials to Develop Advanced Carbon-Negative Materials for Automotive Industry

Today Solvay and Origin Materials announced a collaboration leveraging Origin Materials’ patented technology platform to develop advanced materials for the automotive industry. Petrochemicals PETBottle USRussiaTension

In addition, Solvay has entered into a multi-year capacity reservation agreement for carbon-negative material from Origin Materials.

The advanced automotive materials include a drop-in ready specialty polyamide, a polymer which is extraordinarily stiff, tough, and resistant to heat, corrosion, and high voltage for use in automotive engine applications.

The companies believe these materials will be critical to reach the full potential of automotive decarbonization and achieve the zero-carbon car.1

In becoming an Origin Materials Platform Partner, Solvay will leverage its position as a global leader in chemicals and materials; Origin Materials will leverage its patented disruptive technology platform, which turns sustainable wood residues into cost-advantaged, carbon-negative materials that reduce the need for fossil resources.

-LG Chem bumps up carbon nanotube output to 1,700 tons

South Korea’s LG Chem Ltd. has bumped up carbon nanotube (CNT) output to 1,700 tons after completing production expansion at its Yeosu plant one year after the plan was unveiled, readying to groom CNT business as a new growth engine amid electric vehicle boom after it let battery business go. Petrochemicals PETBottle USRussiaTension

With the expansion of the CNT 2 plant in Yeosu, southern city of Korea, LG Chem now is capable of producing total 1,700 tons of CNT per year, more than tripled from the previous capacity of 500 tons, it said Wednesday.

The Korean chemical company spent a total of 65 billion won ($58.3 million) in the ramp-up since it announced the project a year earlier in April 2020.

-Sustainability : BRFL Textiles aims to increase the Water recycling level to 90%

To shortly increase efficiency of reverse osmosis unit from 50% to 90% resulting in recycling capability of 7.2 million litres of water per day

BRFL Textiles Private Limited (BTPL), home to India’s largest single-roof state-of-the-art fabric processing facility, has set a new benchmark in sustainability by introducing a new sulphur dyeing process by continous dyeing method that does not require water. Petrochemicals PETBottle USRussiaTension

BTPL is the first company in the textile sector to implement this new process of dyeing, making them the pioneers of this innovative sustainable process.

As a sustainable manufacturing unit, BTPL, since inception, has taken efforts to limit carbon emission and recycling of water through multiple ways. The current efficiency of the reverse osmosis unit at BTPL’s Tarapur plant facilitates the unit to reuse 50% of the effluent water, enabling the plant to recycle upto 4 million litres of water per day.

The company is looking to further strengthen this efficiency and aims to increase the recycling level to 90% in the next 3 months, enabling the plant to recycle upto 7.2 million litres of water per day.

Additionally, most of the reactive dyeing processed in the plant is undertaken with e-control process, thereby avoiding salt which in turn avoids increasing the TDS content of water.

-Economic efficiency of plastic recycling plant construction

Solving the problem of plastic pollution is a priority for all of mankind. A significant part of all plastic waste is recyclable and reusable. However, not every method of recycling and reusing plastic is cost-effective. The aim of the study is to justify the economic efficiency of the construction and operation of a plastic recycling plant in the city of Kazan (RussianFederation). Petrochemicals PETBottle USRussiaTension

When performing the calculations, the discounted method for efficiency assessment of investment projects was used. The method involves the calculation of severalefficiency criteria: NPV, IRR, PBP, PI.

The study justifies the economic efficiency of the plant construction project based on the calculated indexes: NPV (net present value of the project) is 182 million rubles, IRR is 41.6 %.

As a result of risk modeling, it was found out that the greatest impact on the net present value of the project is made by an increase in the discount rate. Moreover, the project is highly resistant to a possible reduction in the price and volume of sales, growth in current and investment expenses. Putting the results into practice opens up potential for solving the complex task of saving natural resources, expanding the local raw material base for the production of building materials, and disposing waste having a long decomposition period,more specifically plastic waste.

-Brno Company Pioneers Upcycling of PET Bottles in the Czech Republic

PET bottles are the most- and best-recycled type of plastic in the Czech Republic, but are not made into end products for further use in the food industry due to quality concerns. Until now, there has been no initiative in the Czech Republic to turn used PET bottles into new ones, and drinks producers have had to import recycled PET bottles from abroad. Petrochemicals PETBottle USRussiaTension

A Brno company, rPET In Waste, currently building its operation on the outskirts of the city, is hoping to change this tradition. “Within two or three years, every PET bottle purchased in the Czech Republic will contain material from our company,” said the company’s founder Jiří Hudeček.

“The customer buys a bottle of mineral water, then throws the empty bottle into a yellow container. This then gets taken from the waste-sorting line to the company, which turns it into small plastic flakes that will be transported to this new facility,” explained Hudeček. “We plan to buy these flakes from Czech producers. At rPET In Waste’s new facility, these flakes are processed using a technology that makes the resulting material safe for further use in the food industry, which no company in the Czech Republic can yet do. The beverage manufacturer will be able to buy it again and fill it with their products. The capacity of our line will be somewhere between 1,900 and 2,100 kilograms per hour. We expect to produce about 16,000 tons of regranulate (recycled plastic from production waste) per year.”

-The Circular Plastics Alliance and pledges for plastic recycling

Versalis has joined Circular Plastics Alliance (CPA) The Circular Plastics Alliance and pledges for plastic recycling to actively contribute to the ambitious European target of using 10 million tonnes of recycled plastic in new products by 2025. The Alliance, promoted by the European Commission, with numerous companies and associations across the value chain, aims to encourage plastics recycling in Europe and at the same time develop the market for secondary raw materials.

By joining CPA Versalis has submitted its voluntary pledges in line with its circular economy strategy that is defined by three main pillars: eco-design, recycling technologies and diversification of feedstock.

With regard to eco-design, Versalis has committed to using at least half of its packaging, for transporting products on pallets and in containers, with up to 50% of recycled material. Petrochemicals PETBottle USRussiaTension

In the recycling and diversification of feedstock areas, Versalis has committed to increasing the production capacity of Versalis Revive®, its new line of polyethylene and polystyrene products, containing up to 70% of mechanically recycled plastic. To boost the recovery and recycling of all types of plastics that cannot be mechanically treated, Versalis has pledged to develop a new chemical recycling technology to transform mixed plastic waste into raw material to manufacture new virgin polymers, identical to those originating from fossil sources and suitable for applications, including those that require high quality and performance, such as food packaging.

-GRACE LICENSES UNIPOL POLYPROPYLENE TECHNOLOGY FOR NEW FACILITY IN UZBEKISTAN

W R. Grace & Co. (Columbia, Md.) has licensed its UNIPOL PP Process Technology to the new MTO Gas Chemical Complex located in the Bukhara region of Uzbekistan to Enter Engineering. The UNIPOL PP Technology facility is expected to be launched by-2025 and will include one reactor line with the capability to produce 257,000 metric tons per year (m.t./yr) of polypropylene (PP). Petrochemicals PETBottle USRussiaTension

Enter Engineering Pte. Ltd., one of the largest construction companies in the region, will act as a licensee on behalf of the JV Jizzakh Petroleum LLC who will own and operate the Gas Chemical Complex.

-Plastics Used as Biodegradable Surfactant: Good or Bad Sustainability Solution?

Scientists at Ames Laboratory’s Institute for Cooperative Upcycling of Plastics (iCOUP) have discovered a chemical method that turns recycled plastics into biodegradable, use chemicals that can be used as surfactants and detergents in a variety of applications. Plastics may have more sustainable and cost-effective lifecycles as a result of this process. Petrochemicals PETBottle USRussiaTension

The researchers focused their efforts on deconstructing polyolefins, which account for more than half of all recycled plastics and are used virtually every product imaginable, including toys, food packaging, piping systems, water bottles, clothes, shoes, vehicles, and furniture.

“You might call plastics, especially polyolefins, too successful,” said iCOUP Director Aaron Sadow. “They are good for all of the applications that we need them for – solid, lightweight, thermally stable, chemically resistant – but the issue arises when we no longer use them.”

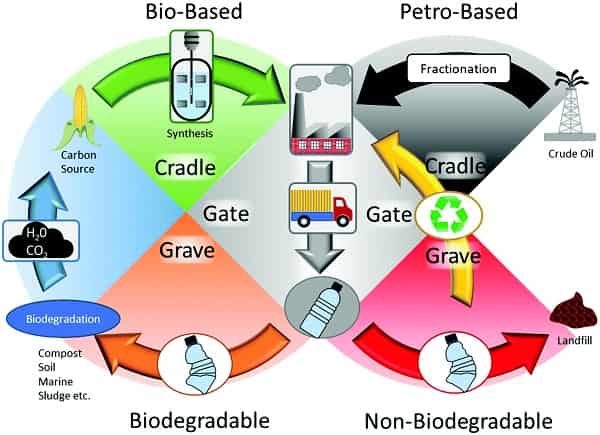

-UK reviews biobased and biodegradable plastics

UK government releases report summarizing stakeholders comments regarding bio-based, biodegradable plastics contribution to circular economy; discusses knowledge gaps; finds lower carbon footprint, potential negative impacts on land-use, waste management; determines use of biodegradables should be limited to specific applications; degradation in the open environment unclear

In April 2021, the Government of the United Kingdom released a summary of their public consultation regarding the potential contribution of bio-based and biodegradable plastics to a more circular economy.

Bio-based, biodegradable, and compostable plastics are seen and widely discussed as part of the solution to achieve a circular plastics economy.

However, many knowledge gaps remain, for example, regarding the overall environmental impacts of bio-based and biodegradable plastic products in comparison with those made from other materials and issues with existing and development of plastic degradation standards. Petrochemicals PETBottle USRussiaTension

From July 22 to October 24, 2019, the British Department for Business, Energy and Industrial Energy and Department for Environment Food and Rural Affairs published a call for public consultation on these aspects.

Petrochemicals PETBottle USRussiaTension