Petrochemicals PETChip Automotive 05-10-2020 - Arhive

Petrochemicals PETChip Automotive

Petrochemical Homopolypropylene Polymers Trend

Crude Oil Prices Trend

-Asia petrochemicals drift in quiet trade as NE region goes on holiday

Spot petrochemical trades in Asia were largely muted at the start of October as most of the northeast region was on holiday.

Before going on a long holiday, China delivered upbeat September manufacturing data, which could buoy up overall sentiment upon players’ return a week later.

Economic data from other countries in Asia, however, calls for a more cautious market outlook.

The slowdown in market activity for some petrochemicals started in the weeks leading to the holiday in China, limiting price movements.

At midday, spot daily prices of toluene, ethylene and propylene were stable from the previous day amid muted discussions, with not much movement in upstream crude futures.

-Italy’s Enel to help build green hydrogen plant in Chile

Italy’s Enel plans to team up with Chilean power company AME and others to install a pilot project to produce green hydrogen in Chile, the utility said on Friday.

The plant, which is expected to be commissioned in 2022, will be the first green hydrogen plant of its kind in the country and one of the biggest in Latin America.

Besides Enel Green Power Chile and AME, other prospective partners include Chilean oil company ENAP, Siemens Energy and Porsche. Petrochemicals PETChip Automotive

Green hydrogen is produced from renewable energy sources using devices called electrolysers. Enel said the Chile plant would be driven by wind power.

Enel, one of the world’s biggest renewable energy companies, is looking to launch a new green hydrogen business to speed up plans to be a carbon-free power producer by 2050.

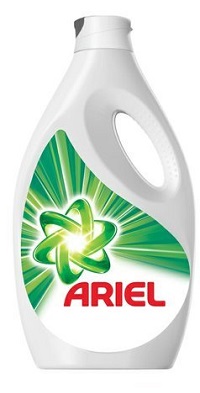

-Finalist interview: P&G’s Ariel bottles with rHDPE

Congratulations on being selected by the international judging panel as a Sustainability Awards 2020 finalist! Could you please introduce your successful entry and what’s innovative about it? Petrochemicals PETChip Automotive

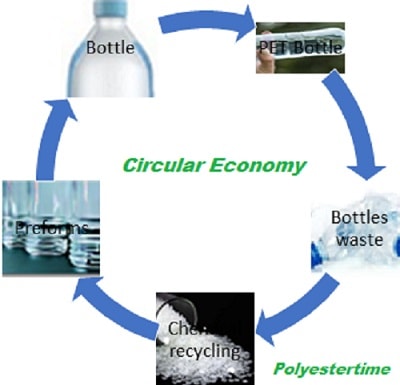

P&G is driving a circular economy for recycled plastics in Europe using our five-pillar model: design for recycling, collection, consumer engagement, innovation in sorting/recycling, and creating end markets.

This entry builds on the creation of significant end markets through the use of recycled polyethylene (rHDPE) resin in Ariel liquid detergent bottles. Using recycled resin up to 50% in HDPE bottles is considered as a major waste reduction strategy.

-PolyCert Europe established to harmonise existing certification schemes for converters

Centexbel-VKC, the Belgian competence centre of plastics and textile, and the Belgian Quality Association (BQA) have established the PolyCert Europe consortium in partnership with the industry associations ECRA, EuPC and ESWA.

The objective of the consortium is to set up a EU-level third-party quality compliance scheme for converters of polymeric materials and to harmonise the methodology for calculation of recycled content used by existing certification schemes in Europe. Such harmonisation is needed to ensure compliance with the relevant standards and regulations and to stimulate circular economy. Petrochemicals PETChip Automotive

The PolyCert Europe scheme will help companies verify compliance with quality standards and ensure their products meet specifications regardless of whether they use virgin or recycled polymers. At the same time, the objective is to provide converters with a quality certification and verification of recycled content in converted products.

-Sasol to raise $2 billion in part sale of U.S chemicals unit to LyondellBasell

South Africa’s Sasol SOLJ.J said on Friday chemical company LyondellBasell Industries LYB.N had agreed to acquire a 50% stake in a unit of its U.S-based business for $2 billion, helping the petrochemicals firm to cut debt.

As part of the agreement, the two companies will form a 50/50 joint venture which will take over the base chemicals business at Lake Charles. LyondellBasell will be the operator of the new JV firm, Sasol said. Petrochemicals PETChip Automotive

The Lake Charles project consists of seven manufacturing units for products used in cleaning, detergents and cosmetics.

Sasol said it will retain full ownership of the U.S performance chemicals business as well as the original ethane cracker.

“The transaction will represent a significant step towards achieving Sasol’s strategic and financial objectives by materially reducing net debt,” the company said.

-Silk-producing bacteria next target for engineers

Team from Rensselaer Polytechnic Institute exploring genetically engineered microorganism that “eats” petroleum-based plastic waste and converts it to a biodegradable plastic alternative

Each year tens of millions of tons of plastic are sent to landfills, while another eight million metric tons of plastic end up in the ocean. It’s an exponential problem that requires an environmentally friendly solution. Petrochemicals PETChip Automotive

In order to vastly improve the Earth’s health, that waste needs to be broken down for reuse, but determining how to do this effectively and efficiently has been a persistent challenge.

With the support of a new National Science Foundation grant, a team of engineers from Rensselaer Polytechnic Institute will explore a potentially transformative idea: genetically engineering a microorganism that “eats” petroleum-based plastic waste and converts it to a biodegradable plastic alternative.

-Nonwovens Made of Circular Polypropylene a First for Hygiene Applications

The collaboration between Sabic and Fibertex Personal Care brings sustainability to personal hygiene products.

Chemicals giant Sabic is collaborating with Fibertex Personal Care, one of the world’s largest manufacturers of spun-bond nonwovens for the hygiene industry, to create nonwovens using high-purity recycled plastics from Sabic’s TruCircle portfolio. This will be the world’s first nonwovens range based on recycled plastics in the hygiene industry, said Sabic. Petrochemicals PETChip Automotive

The new nonwovens will be made from Sabic’s circular polypropylene, using feedstock derived from previously used plastics, certified under the International Sustainability & Carbon Certification (ISCC) Plus system. The material is part of the Sabic PureCares portfolio of polypropylene for personal hygiene applications that was introduced at the beginning of this year.

Cargill and Virent, Inc. are working together to evaluate the use of Cargill’s corn dextrose as a feedstock to Virent’s BioForming technology for the production of “drop-in” low-carbon biofuels and biochemicals. Petrochemicals PETChip Automotive

Virent’s BioForming technology uses sugars found in plants as a feedstock to produce drop-in renewable gasoline and jet fuel, as well as lower carbon biochemicals, including bio-paraxylene, a key raw material for producing 100% renewable and recyclable biopolyester.

-Combining PET-degrading enzymes together speeds up the breakdown process

Two years ago, researchers at the University of Portsmouth in the UK and the NREL in the USA identified an enzyme capable of degrading PET, called PETase. Now, an enzyme found in the rubbish dwelling bacterium that lives on a diet of plastic bottles, has been combined with PETase to speed up the breakdown of plastic. Petrochemicals PETChip Automotive

Two years ago, researchers at the University of Portsmouth in the UK and the NREL in the USA identified an enzyme capable of degrading PET, called PETase. Now, an enzyme found in the rubbish dwelling bacterium that lives on a diet of plastic bottles, has been combined with PETase to speed up the breakdown of plastic.

Petrochemicals PETChip Automotive