Petrochemicals PETPolymer Automotive 28-04-2021 - Arhive

Petrochemicals PETPolymer Automotive

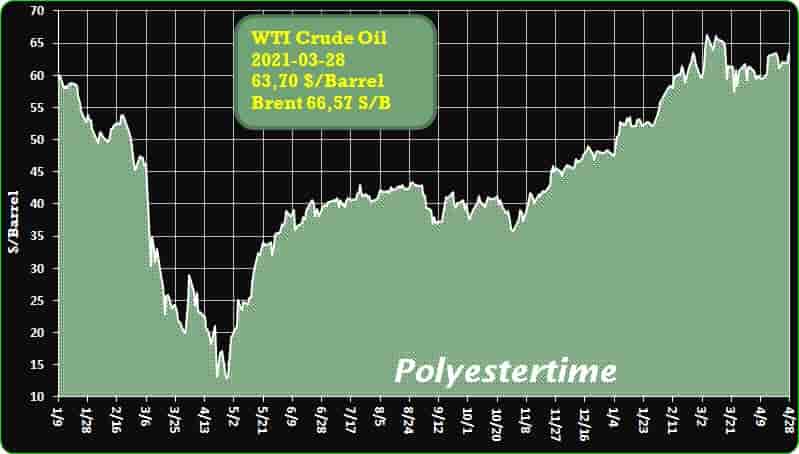

Crude Oil Prices Trend

-Israeli manufacturer Nilit launches sustainable premium nylon fibre

Nilit, an Israel-based manufacturer of nylon 6.6 (polyamide) fibres, has introduced Sensil BioCare, a sustainable nylon fibre that breaks down faster in seawater and landfills. The fibre is developed to help the textiles and apparel industry address specific environmental challenges such as water consumption and its impact on the ecosystem.

Responsibly manufactured according to Nilit’s Total Product Sustainability (TPS) criteria, Sensil BioCare enhanced with special technology will not wear or wash out nor will it interfere with other performance additives, finishes or dyes, said the company in a press release.

“We designed our new Sensil BioCare to help reduce the potential impact of synthetic fabrics on the Earth’s ecosystems,” says Ilan Melamed, general manager, Nilit. “We provide consumers the same performance, comfort, and durability they expect from Sensil premium nylon along with the peace of mind that they are making a positive choice for the planet.”

SABIC today launched new bio-based LNP™ THERMOCOMP™ DC0041PE-7M1D145W compound, offering customers a new sustainable option for demanding applications in electrical/electronics, healthcare and other key industries. This new flame-retardant, carbon fiber-reinforced compound has a reduced carbon/energy footprint compared to its incumbent product, LNP THERMOCOMP DC0041PE-7M1D145 compound, while delivering the same properties.

“SABIC continues to invest in cutting-edge research and development focused on improving the sustainability of our products without compromising on performance and processability,” noted Joshua Chiaw, Director, Business Management, LNP Compounds & NORYL Resins, SABIC. “All aspects of the value chain, from raw materials to finished goods, are certified through ISCC and compliant with regional and global regulations. The success of our first bio-based compound is inspiring us to accelerate our innovation efforts to develop totally new ways to support customers and protect the planet.”

-Adding enzymes to bioplastics can make them disappear

New research shows there may be a way to make easily biodegradable single-use plastics.

With so many different plastics entering the waterways that take hundreds of years to decompose, plastic pollution and microplastics are almost everywhere on the planet, from the air to the sea, in vast quantities. Compostable plastics, like corn-based plastic cups and straws, are sometimes touted as a viable solution, but without the infrastructure to properly turn them into compost, they can end up in a landfill.

To keep our oceans from becoming even more plastic-filled, scientists are finding the keys to making plastics quickly decompose, and baking them into the plastic’s formula. Ting Xu, professor of materials science and engineering and chemistry at the University of California Berkeley, and her research group investigate biologically available solutions that will allow single-use plastic to biodegrade under easily attainable conditions. In a new study, they describe how they used an innovative polymer coating on enzymes that can be built-in to bioplastics to make them easier to compost at home.

-Net Zero Plastic Applies Carbon-Offset Model to Plastic Waste Reduction

Yankee Scientific Inc. and CO2 Global claim to have developed a comprehensive market-based business platform for the environmentally responsible management of plastic waste. According to Eric Guyer, President of Yankee Scientific, the patented Net Zero Plastic technical and business method can be deployed commercially today and is responsive to rapidly changing public sentiment about the importance of environmental sustainability. “Importantly, it is not dependent on the development of new technology,” said Guyer. “Rather, our platform represents a new synthesis of business concepts and technical capability.”

The key features of the Net Zero Plastic platform are:

- Elimination of unwanted plastic waste by processing it in ways that minimize or eliminate carbon emissions.

- Application of the well-established concept of environmental offset together with eco-branding to guarantee environmental responsibility in the use of plastic products, including those conventionally produced from fossil hydrocarbons.

- Economic mining of the environmental concern about plastic waste at the point of maximum plastic material value.

- A measurement, verification, and accounting system.

Yankee Scientific Inc. and CO2 Global explain that for every pound of eco-branded Net Zero Plastic product that is bought, “the platform guarantees an equivalent pound of plastic waste is permanently eliminated from the earth in an environmentally responsible way.”

The missing link in recycling programs

Guyer explained to PlasticsToday that the idea of producer responsibility is the missing link in the scheme of recycling. “We’ve identified a strategy that would work across the industry without a lot of disruption and with minimal cost by getting people to label their plastic products as they make them,” Guyer said. “For every pound of plastics they label, we’ll collect and incinerate an equal amount of plastic waste in a waste-to-energy plant equipped with a carbon capture system.

-Production lines for PC speciality films started at German site Dormagen

German plastics producer Covestro (Leverkusen; www.covestro.com) has started up additional production lines for polycarbonate speciality films at its Dormagen site in Germany, the construction for which had begun in May 2019 (see Plasteurope.com of 07.05.2019). The new coextrusion lines are part of the company’s global programme to expand film capacity, with an investment of over EUR 100m. Around 30 new jobs will be created to operate the new lines, which will mainly produce multilayer flat films that are used in medical technology, car interiors and ID cards.

“Our new production lines are equipped with state-of-the-art technology,” says Thorsten Dreier, global head of speciality films and thermoplastic polyurethanes business, and adds,

The Chinese-born chemist planned to use the stolen IP to set up her own BPA-free coating company in China.

A chemist was found guilty on April 22, 2021, for her role in a scheme to steal trade secrets related to bisphenol-A-free (BPA-free) polymers from American companies that include Coca-Cola and Eastman Chemical Co. Chinese-born Xiaorong You, PhD, aka Shannon You, plotted to steal the IP worth an estimated $120 million and set up her own BPA-free coating company in China, according to the Department of Justice (DOJ) news release.

Following the 12-day trial, You was convicted of conspiracy to commit economic espionage, conspiracy to steal trade secrets, possession of stolen trade secrets, economic espionage, and wire fraud. According to the DOJ press release, court documents and evidence presented at the trial revealed You stole valuable trade secrets related to formulations for BPA-free coatings for the inside of beverage cans for the purpose of establishing a global can-coating manufacturer in China with Chinese chemical company Weihai Jinhong Group.

-Chemical Recycling of Post-Consumer PLA Waste for Sustainable Production of Ethyl Lactate

Though synthetic plastics are indispensable in our everyday life, the uncertainty surrounding the sustainability of fossil reserves has led to the development of a novel class of plastics, referred to as bio-based plastics. Poly(lactic) acid (PLA) is the most frequently used member of this family. However, due to the lack of a holistic recycling strategy, its large scale utilization can turn out to be an acute source of plastic pollution in the future. Unlike other attempts directed towards chemical recycling of PLA which violate the basic principles of green chemistry, the following research establishes an eco-friendly recycling concept aimed at the production of a valuable lactate ester through solvent assisted transesterification of PLA waste. The scope of this research is not only limited to the selection of an appropriate system (solvent, nucleophile and catalyst) but also extends to analysing the selectivity of the solvent towards the PLA fraction in a commingled stream and the effect of the concentration of nucleophile and different PLA substrates on the yield of the lactate ester.

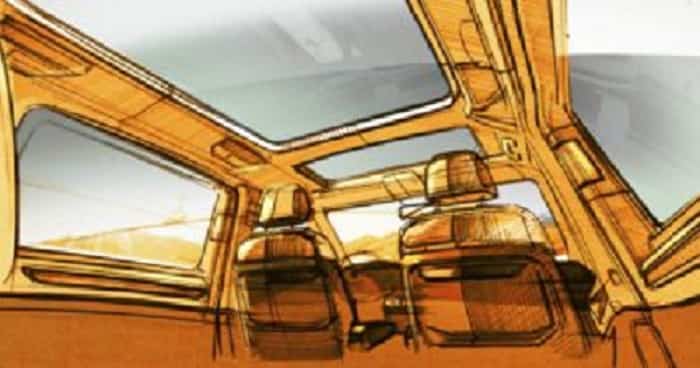

-VW teases revamped Multivan interior

VW teases revamped Multivan interior Volkswagen Commercial Vehicles has presented concept drawings for its latest Multivan, which it says will have the most flexible interior system that a Bulli (Transporter) has ever had.

The design features the existing model’s signature touches, including a high seating position in the front with up to five moveable/removeable individual seats in the back. The second row of seats can be rotated 180°, enabling the rear seats to be arranged in the typical face-to-face arrangement of the Multivan. This is a concept that originates from the Multivan T3 (launched in the 1980s) and VW says it has been a winning formula for over 35 years.

Albert Kirzinger, head of design at Volkswagen Commercial Vehicles, explained why flexible seats and a middle seat that is both moveable and removeable are so important for a Multivan: “It is wonderfully practical. And a car is practical, if it can be used flexibly. To that end, we’ve created a new seating system. You can easily take seats out to get your sports equipment, mountain bike and/or surfboard into this generously proportioned space. With these seats, everything is possible in the new Multivan.”

VW teases revamped Multivan interior Volkswagen Commercial Vehicles has presented concept drawings for its latest Multivan, which it says will have the most flexible interior system that a Bulli (Transporter) has ever had.

Textiles are no more limited for use as apparels clothing is just are but not the only purpose of textiles with the rapid changes in the social economic structure of our society.

Many efforts are made to some and protect human life.

Textiles are used in a number of little known forms and less transparent technical areas. Automotive textiles is one of them.

It is estimated that an average family car contains about 12-14kg of textiles. The biggest car producing region is Western Europe, which consumes 1, 50,000 tons per annum of textile for the automotive industry.

The second and third largest markets for automotive textiles are USA and Japan. Two-third of textile are used for interior trim, that is, seat covers, roof, door liners, and carpets.

Remainder goes to the other parts of the automotives.

The world biggest nonwovens manufacturer estimates 42% of its sales tied to the automotive sector.

-Cordura with hemp – a winning combination

Invista is this year marking the tenth anniversary of the Cordura Denim brand with new fabrics featuring hemp.

“Cordura Denim is proven to be at least four times more durable than traditional 100% cotton equivalents and has found a firm fan-base as the comfortable, durable option for skateboarders, climbers, cycle commuters, workers and motorcyclists,” said business development director Cindy McNaull. “Our Cordura Lab to Life denim testing protocol supports sustainability, focusing on built-in resistance to abrasion and tear.”

This built-in strength, she added, is based on denims engineered from a blend of Invista’s military-grade T420 nylon-6.6 staple fibre and cotton.

“We design and engineer with a view to the future with the aim of creating denims that reflect innovation and heritage while encapsulating next generation durability, strength and added performance, while also being sustainable. This is where hemp comes in, offering enhanced abrasion resistance, tensile and tear strength as well as aesthetic advantages and eco-efficient properties.”

Petrochemicals PETPolymer CrudeOil