Petrochemicals PETPolymer CrudeWTI 29-04-2021 - Arhive

Petrochemicals PETPolymer CrudeWTI

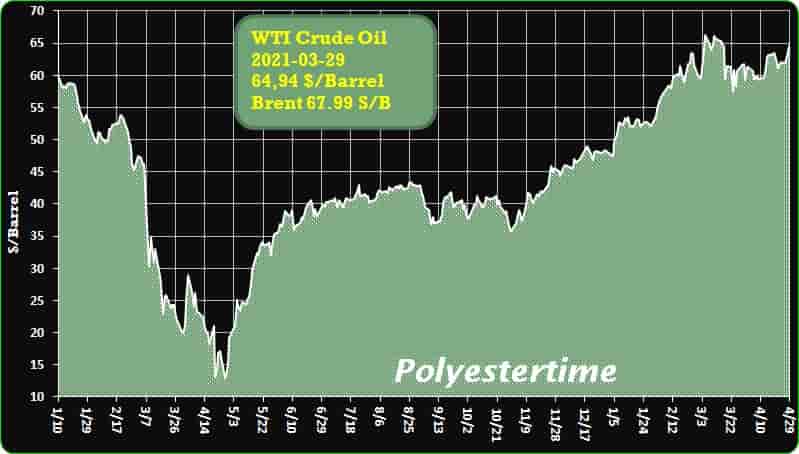

Crude Oil Prices Trend

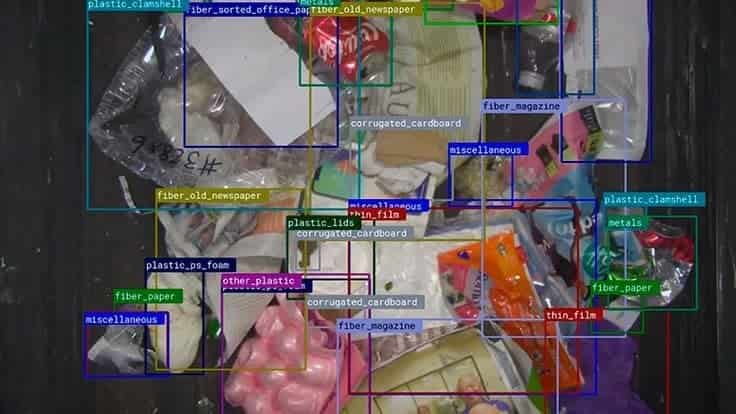

-Amp Robotics introduces material characterization software

The AI-powered technology enables the recognition and classification of recyclables in different stages of the recycling process.

Amp Robotics Corp., Denver, has introduced Amp Clarity, artificial intelligence- (AI-) powered material characterization software that enables the recognition and classification of recyclables as they flow through the different recovery stages of the recycling process. The company says the technology provides “measurable transparency on the recyclables captured and missed during different recycling processes, as well as confirming the composition of recovered material bales destined for resale to end markets in the supply chain.”

“Data transparency in the recycling industry has been a longstanding challenge due to the complexity of mixed material streams, compounded by ongoing changes in consumer packaging,” says Matanya Horowitz, founder and CEO of Amp. “These obstacles often create impediments to accurate data collection and prevent a clear understanding of what goes into and comes out of the different infrastructure stages that support recycling.”

He continues, “Our material characterization software digitizes the real-time flow of recyclables with precision and consistency, providing opportunities to identify gaps in material capture, transparency on what recyclables are and are not recycled and a basis for standardized measurement vital to improve our national recycling system.”

Amp Clarity captures data on plastics, such as polyethylene terephthalate (PET), high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene (PP) and polystyrene (PS); aluminum recyclables such as used beverage cans (UBCs); and fiber, such as corrugated cardboard (OCC) and sorted residential paper and newsprint (SRPN).

-Discover new interior materials, technologies, concepts, comforts, innovations and suppliers

Automotive Interiors Expo Europe exhibitors represent the A-Z of car interiors, with our exhibitors’ products being found in vehicles from just about every car manufacturer you can name, from Ferrari, Maserati, McLaren and Porsche through to GM, Volkswagen, Jaguar, BMW, Kia Toyota and Chery to name just a few!

The show is about quality, color, texture, touch, feel and innovation. Specialty finishes are a strong theme of the expo, with some companies offering plastic compounding and master batching, metalized plastics and chrome-look plastics, and others presenting hot foil stamping and film insert molding.

You’ll find a wide range of fabrics, acoustical materials, shape-forming materials and foams, fasteners and adhesive systems, lighting and more! The show is a must-visit for Tier 1 suppliers as well as for interior design teams from car manufacturers wanting to keep up with the rapidly changing world of materials, finishes and technologies that contribute to ‘touch and feel’.Petrochemicals PETPolymer CrudeWTI

-Repsol to join Ecoplanta project to build waste to chemicals plant in Spain

Spain’s Repsol will join the Ecoplanta project, together with the technology leader Montreal-based firm Enerkem and Agbar, a global expert in water and waste management, to build a waste to chemicals plant in Tarragona, Spain, according to Hydrocarbonprocessing.Petrochemicals PETPolymer CrudeWTI

Under the joint venture Ecoplanta Molecular Recycling Solutions, the plant will process around 400,000 tons of non-recyclable municipal solid waste from its surrounding regions and produce 220,000 tons of methanol.

This methanol will be used as raw material to produce circular materials or advanced biofuels, contributing to avoid 200,000 tons of CO2 and reducing the waste that ends up in the landfill. This alliance is a further step towards the multi-energy company’s ambition to become a net-zero emissions company by 2050.

The plant, the first of its kind in the Iberian Peninsula, will be co-managed by Repsol and Agbar, whilst Enerkem will be the key technological partner.

-The Curious Case of Advanced Recycling Company New Hope Energy

A recent announcement from New Hope Energy LLC said the advanced chemical recycling company signed a long-term agreement with Chevron Phillips Chemical to provide ISCC Plus–certified renewable chemical feedstock produced through pyrolysis. But the story isn’t so simple. It rarely is when you’re dealing with so-called advanced recycling companies.Petrochemicals PETPolymer CrudeWTI

After doing some digging, I tried contacting New Hope Energy. Attempts to reach its Phase I plant in Tyler, TX, where the company is headquartered, were unsuccessful. There is no phone listing for the facility, and e-mails were returned as being invalid. The plant, which opened in July 2019, experienced a fire in May 2020, according to news reports. No information on the state of the facility or its current operations could be found.

Pyrolosis without combustion

Johnny and Karen Combs own New Hope Energy, which began life in 2008 as Renewable Diesel Micro Refinery (RDMR), a company with the stated purpose of building modular micro-refineries that could be placed anywhere in the world to turn waste plastic into fuel. In 2013, the company became a DBA of RDMR, named New Hope Energy. New Hope’s “patented pyrolysis process thermally decomposes plastics into hydrocarbon products without combustion,” said the company.

-Sabic and Plastic Energy Tap Worley to Build Advanced Recycling Plant in Netherlands

Worley, a global engineering, procurement, and construction management (EPCM) firm, has been awarded the contract to build the advanced recycling plant for Sabic Plastic Energy Advanced Recycling BV. A joint venture between Sabic and Plastic Energy, the plant will be located in Geleen, Netherlands.

The facility will leverage Plastic Energy’s patented recycling technology to transform mixed and used plastic waste, otherwise destined for incineration or landfill, into recycled oil called Tacoil.Petrochemicals PETPolymer CrudeWTI

The Tacoil will then be used by Sabic as an alternative feedstock to manufacture certified circular polymers as part of its TruCircle portfolio.

“We are excited to build our relationship with Sabic and Plastic Energy as we move forward into a more productive world of recycled plastics,” said Bradley Andrews, President for UK, Norway, Central Asia, and Eastern Europe at Worley. “This project will help transform the global use of plastics, move us closer to achieving a circular economy, and support our strategic focus on delivering a more sustainable world.”

-Sustainability, performance on the rise with new Sabic materials

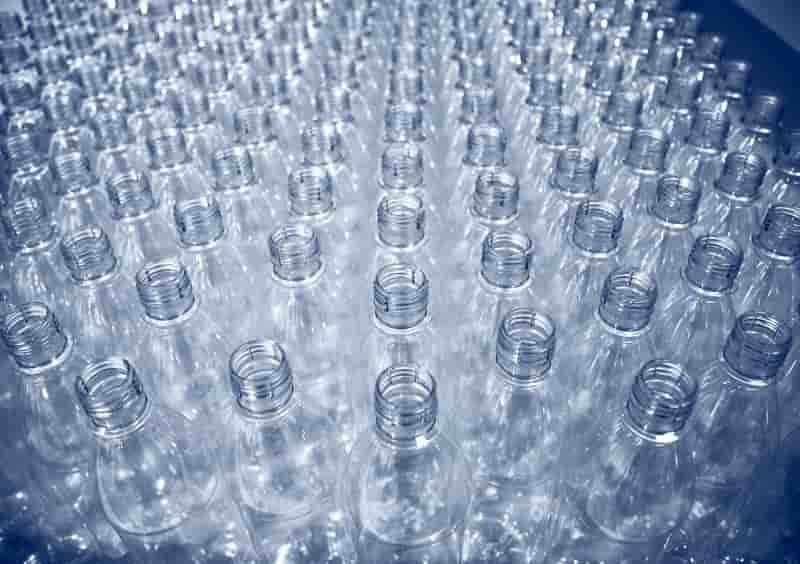

Sabic has diverted more than 100 million single-use 16.9-ounce PET water bottles from landfills and incinerators since late 2019 by using them as feedstock for its Elcrin IQ-brand PBT materials.

Saudi Basic Industries Corp. has improved sustainability and performance with new materials. Petrochemicals PETPolymer CrudeWTI

The firm — based in Riyadh, Saudi Arabia, with U.S. headquarters in Houston — will soon be launching a new LNP Thermocomp-brand compound, its first bio-based product. The new material offers customers a more sustainable option vs. competitive materials for demanding applications in electrical/electronics, health care and other key industries, officials said.

“A lot of our customers are asking how they can make it to 100 percent sustainability,” Darpan Parikh, global product management leader, said in an interview with Plastics News. “They want to use everything existing and available in the waste stream.”

For every 100 kilograms of the new compound, 21 kilograms of fossil-based materials have been replaced with bio-based materials derived from waste or residue, such as crude tall oil and hydrotreated vegetable oils, officials said. The new compound also incorporates more than 50 percent recycled content from post-consumer plastic and pre-consumer carbon fiber sources.

-Fibertex to expand European operations

Fibertex Nonwovens has announced the second stage of its expansion plan with an investment of DKK 300 million in the company’s plants in the Czech Republic and Turkey.Petrochemicals PETPolymer CrudeWTI

The investment was prompted by increased global demand for the company’s high-tech and sustainable speciality products.

In March 2021, Fibertex Nonwovens, a subsidiary of the Danish industrial conglomerate Schouw & Co. in Aarhus, Denmark, announced an investment of just over DKK 300 million in a capacity expansion of one of the company’s two plants in the USA. Fibertex Nonwovens is now investing the same amount in Europe with a capacity expansion of the company’s existing plants in the Czech Republic and Turkey.

-Carbios announces the signing of an Expression Of Intent agreement with a major PET producer

Significant PET producer could host a 100% PET recycling production unit using Carbios’ technologyPetrochemicals PETPolymer CrudeWTI

With this second EOI agreement, Carbios confirms its plan to build a first-of-a-kind production unit after site selection to be completed in 2022

Carbios, a company pioneering new enzymatic solutions to reinvent the lifecycle of plastic and textile polymers, announced that a non-exclusive and non-binding Expression Of Intent agreement was signed with a significant PET producer on April 15th, 2021.

With this additional agreement, as announced on April 6th, 2021 (1), Carbios confirms its plan to build a first-of-a-kind 100% PET recycling production unit using its enzymatic technology (the “Unit”). The company will carry out ongoing studies to select the most suitable site, technically and economically, to build this first industrial and commercial Unit.

-MAIRE TECNIMONT AWARDED EPCC CONTRACT FOR IOCL’S NEW PARA-XYLENE PLANT

Maire Tecnimont S.p.A. (Rome, Italy) announced that a consortium composed of its subsidiaries Tecnimont S.p.A. and Mumbai-based Tecnimont Private Limited has been awarded an EPCC (Engineering, Procurement, Construction and Commissioning) Lump-Sum contract by Indian Oil Corporation Limited (IOCL), for the implementation of a new Para-Xylene (PX) plant and the relevant offsites facilities. The plant will be located in Paradip, in the State of Odisha, in Eastern India.

The overall value of the contract is about $450 million. The scope of work entails EPCC activities up to the Performance Guarantees Test Run. Once completed, the new PX plant will have a capacity of 800,000 metric tons per year (m.t./yr). The time schedule is 33 months for Mechanical Completion from the award date. The PX produced will be used to feed the adjacent PTA (Purified Terephthalic Acid) unit, thus ensuring availability of world-class feedstock that will provide a significant boost to the Country’s manufacturing industry. Petrochemicals PETPolymer CrudeWTI

-Will VFY export of China hit new highs in 2021?

VFY price continued to rise in the first quarter of 2021. Driven by stronger textiles amid the control of the epidemic and the expected recovery of economy and demand, combined with the support of VFY sales and feedstock cost, VFY price was gradually moving closer to the level at the beginning of 2020. By late Apr, the offer of bright VFY 120D had increased to 38,000-41,000yuan/mt. Petrochemicals PETPolymer CrudeWTI

Pulp price kept rising amid continued tight supply and VFY price recovered somehow, but the pressure from cost still weighed on the profit of VFY companies.

Overseas demand continued to be strong in the first quarter, and the monthly export volume hit a record high. However, the demand in China local market was relatively stable, which had not recovered to pre-epidemic level. In Mar 2021, VFY export of China set a record high of 9,681kt, up 16.02% m-o-m and up 30.45% y-o-y.

Petrochemicals PETPolymer CrudeOil