Petrochemicals PETPolymer Nonwovenfabric 26-04-2021 - Arhive

Petrochemicals PETPolymer Nonwovenfabric

Petrochemicals PETBottle R-POYPolyester Trend

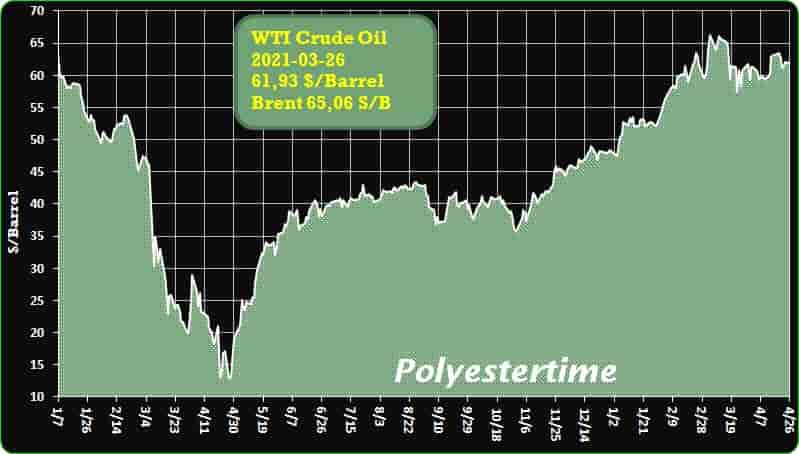

Crude Oil Prices Trend

-Arkema to Start Up New Bio-Based Polyamide 11 Plant in Singapore in the First Half of 2022

Arkema (Paris:AKE) confirms it is on track to begin production of Amino 11 and its flagship Rilsan® polyamide 11 high performance polymer at the new plant on Jurong Island, Singapore in the first half of next year. This plant, for which production will be 100%-derived from renewable castor beans, represents a 50% increase in Arkema’s global polyamide 11 capacity.

With this ambitious project announced in 2017, Arkema is delivering on its strong commitment to Specialty Materials and the bio-based polyamide 11 chain. When complete, this will represent the biggest integrated bio-factory in the world dedicated to high performance polymers. It represents a 50% increase in global polyamide 11 capacity for Arkema. The total investment in the region, which also includes downstream polymer capacities in China, is approximately €450 million. To finance this new plant in Singapore, Arkema successfully placed its first ever green bond in October 2020, for a total amount of €300 million.

After a first phase of in-depth studies and administrative procedures, our technical teams have started work on the infrastructure and construction of this large-scale industrial complex on the Jurong site (Singapore). After overcoming the difficulties linked to the Covid-19, this project is fully on track and the Group confirms its ambition to start up production in the first half of 2022.

-How Russia Could Kickstart Another Oil Price War

Russia’s President Vladimir Putin is starting to feel the heat of new U.S. sanctions, as Washington is putting some additional bite into its confrontation with Moscow.

At the same time, new sanctions or even a full-out (proxy) confrontation are looming on the horizon, looking at the tensions at the Russian-Ukrainian border. Putin’s reactions are straightforward, threatening asymmetric responses to any Western pressure or military interference in the coming months.

The still fledgling or outright weak reactions of Western governments, especially in Europe, are received in Russia as a sign of weakness. Even though current US-EU sanctions on Russian institutions and oligarchs are taking their toll, the larger picture hasn’t changed much.

Russia’s military buildup on the eastern Ukrainian border, the unilateral decision to block the Black Sea for international shipping and naval forces, in breach with the Montreux Convention, and the threat of increased US sanctions on the NordStream 2 involved parties, doesn’t seem to have changed Putin’s strategic considerations. The global critique about the Russian treatment of Navalny is seen by Moscow as external interference in an internal issue, not to be discussed even during Putin’s yearly “State of Union” address to the Russian people.

-Oerlikon Acquires INglass and HRSflow Hot-Runner Business

Oerlikon, a supplier of surface engineering, polymer processing, and additive manufacturing services, has signed an agreement to acquire Italy-based INglass SpA and its hot-runner technology operating under the HRSflow brand. The acquisition represents a significant step in expanding Oerlikon’s current manmade fibers business into the larger polymer processing market, said the company, which has its headquarters in Pfäffikon, Switzerland.

Completion of the transaction, subject to customary regulatory approvals, is expected by the second quarter of 2021. Petrochemicals PETPolymer Nonwovenfabric

Oerlikon said that its Manmade Fibers Division will be renamed Polymer Processing Solutions Division to reflect its expansion into this high-growth market. The division will comprise two business units: Flow Control Solutions and Manmade Fibers Solutions. The former will combine the expertise of Oerlikon Barmag’s existing gear metering pumps business line with INglass’s HRSflow operations. Manmade Fibers Solutions will continue to focus on growing the existing chemical fiber machinery and plant engineering business for the production of polyester, polypropylene, and polyamide.

-Coca-Cola, Unilever and Colgate-Palmolive join AB InBev’s sustainability accelerator

Today, The Coca-Cola Company, Colgate-Palmolive Company and Unilever have joined the Anheuser-Busch InBev (AB InBev) 100+ Accelerator, an initiative that aims to fund and pilot sustainable innovation in supply chains.

Launched in 2018, the 100+ Accelerator is a global incubator program that works to solve supply chain challenges across water stewardship, circular packaging, upcycling, sustainable agriculture and climate action. Over the last two years, the program has accelerated 36 companies in 16 countries.

Tony Milikin, chief procurement, sustainability and circular ventures officer at AB InBev, said: “We are absolutely thrilled to have The Coca-Cola Company, Colgate-Palmolive and Unilever join us as founding partners in the 100+ Accelerator.”

“Together, we are striving to supercharge adoption of sustainable solutions by funding and accelerating fantastic innovations that will change the world by making all of our businesses more sustainable. Sustainable business is smart business, and we are working to solve huge problems that no one company can handle alone. With our combined global reach, we can accelerate progress towards a more sustainable future.” Petrochemicals PETPolymer Nonwovenfabric

-Evergreen to expand rPET production

Company to double food-grade rPET output to 80 million pounds by mid-2022.

Plastics recycling company Evergreen is undergoing an expansion at its plant in Clyde, Ohio, that will double its food-grade recycled polyethylene terephthalate (PET) processing capacity from roughly 40 million pounds annually to 80 million pounds annually, says Greg Johnson, Evergreen corporate vice president.

Late last year, the company added six robots on its sorting line that were supplied by Amp Robotics of Denver, Colorado. Petrochemicals PETPolymer Nonwovenfabric

The robotic sorters are after the optical sorters on the whole bottle sorting line, and Johnson says they have helped to improve the consistency and quality of the material. He adds that the robots are negatively sorting the PET bottles, removing colored bottles or those with certain labels and non-PET bottles that may have gotten past the optical sorters.

He says the robots provide the “final polish” and “are not a replacement for optical sorters.”

-First CAC biodegradable wipe substrates

Mondi’s new CAC (carded-airlaid-carded) line is now producing samples for qualification at the company’s plant in Germany, having started up in February.

“This is the first machine of its type producing nonwovens based on composites of staple fibre and airlaid pulp,” explained the company’s director of R&D Michael Trinkaus during the online EDANA Outlook conference (April 21-23). “The nonwoven layers are combined by hydroentanglement without the use of binders to produce materials that are 100% renewable, biodegradable and compostable.”

The resulting nonwovens for wipes are tough on mess, while being gentle to the touch, with a stable 3D texture, he added. The viscose and pulp combination also results in a high surface area. Other advantages include the pattern stability of the materials made by the CAC progress, with the short fibres strongly positioned by the hydro-moulding step. Petrochemicals PETPolymer Nonwovenfabric

This also ensures the lotion in wipes stays where it should.

-Biotransformation technology for polyolefin fibres and nonwovens

Indorama Ventures’ fibre manufacturer FiberVisions and nonwovens manufacturer Avgol have partnered with the Polymateria to commercially harness the ‘biotransformation’ technology pioneered by the UK-based company. The patented technology alters the properties of polyolefins to make them biodegradable in a natural process. Petrochemicals PETPolymer Nonwovenfabric

The Biotransformation Technology will enable the companies to bring disposable products a unique managed lifecycle and further expand an already extensive catalogue of fibre/spunlaid offerings. The focus of these efforts will be in the launch of non-oxo-degradative components for personal protection masks and face covering, hygiene, agricultural, industrial and homecare applications.

The use of Biotransformation Technology will support applications in non-virgin resin recycling while providing a solution for ‘fugitive’ used articles, including those items that have not been properly recycled or disposed of. This process involves the material decomposing into a wax, wherein the wax is further degraded by environmental bacterial action into carbon dioxide, water and biomass.

-Berry Global to invest $70m to expand sustainable film capacity in North America

The investment will enable Berry Global to expand its portfolio of fully recyclable, biodegradable or compostable films Petrochemicals PETPolymer Nonwovenfabric

Berry Global Group, a provider of packaging and engineered products, is set to invest over $70m to expand its capacity for consumer packaging films.

The latest investment is believed to help continued growth in consumer packaging films, specifically for e-commerce, food, and beverage applications.

Berry Global will use the funds to build new multi-layer blown film lines, as well as upgrade infrastructure and other equipment across multiple sites in the North American manufacturing system.

The expanded capacity is expected to be operational between this year and 2022.

The new film lines will support the anticipated increased customer demand for recycled content, apart from the traditional infrastructure upgrade.

Berry stated that line flexibility is a crucial investment strategy deployed by the company to make sure that ongoing material science developments applied to customer specifications ranging from recycled content in its films to PHA resins that facilitate bio-resin use.

-Indorama expands Deja sustainable brand platform

Deja Carbon Neutral PET pellet is the latest innovation under IVL’s Deja global brand offering a certified carbon neutral PET pellet solution.

Indorama Ventures (IVL) is expanding its portfolio of sustainable solutions under its Deja brand. The global sustainable ingredients brand is a key part the company’s commitment to meet growing demand for innovative, high performance products which will reduce its impact on the environment. Petrochemicals PETPolymer Nonwovenfabric

Deja Carbon Neutral PET pellet is the latest innovation under IVL’s Deja global brand offering as the world’s first certified carbon neutral PET pellet solution. It is a significant addition to the growing Deja portfolio, which includes sustainable PET, rPET, polymer and fibre range of products available across flake, pellet, fibre and filament ingredients. Deja Carbon Neutral PET pellet has been sustainably produced throughout its supply chain and helps environmentally conscious companies to achieve their sustainability targets by lowering their Scope 3 GHG emissions.

Petrochemicals PETPolymer Nonwovenfabric