Petrochemicals PETPolymer Packaging 27-04-2021 - Arhive

Petrochemicals PETPolymer Packaging

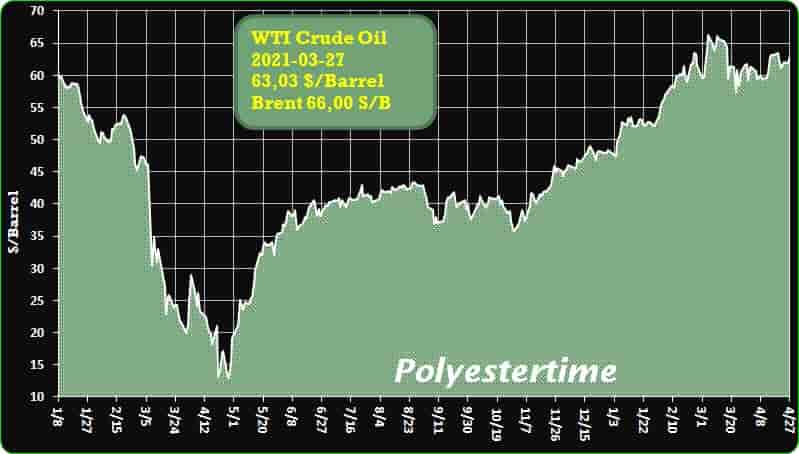

Crude Oil Prices Trend

-Resilux set to double bottle-to-bottle recycling capacity using Erema technology

Resilux, a leading PET bottle and preform producer, has announced a major new technology investment which will result in them doubling their bottle-to-bottle PET recycling capacity.

Using state of the art equipment from Erema, it is Resilux’s latest step in their drive to create a truly circular economy in PET. The new VACUNITE® bottle-to-bottle system enables Resilux to significantly ramp up their production of food grade recycled PET. The new investment has been made in response to increased customer demand and the expectation that production will only increase in the future. Marcel van de Sande, Resilux Group Chief Operating Officer, says “the new technology puts us in the perfect position to ride the next green wave” by using the “Power of PET”.

-Polyester downstream market: Attention to textile orders in late-May

The pandemic burst again in India since late-Mar. As of April 24, India has become a country with the largest new infection in the world for three consecutive days, and the number of newly added cases reached 346,000 on Apr 24, which was the maximum daily number of new cases worldwide since the outbreak of the COVID-19 pandemic.

Some orders for textiles and apparels in India were rumored to flow into China last week as the pandemic was almost out of control there. After communicating with downstream players on polyester market, there was no such transfer temporarily. Some PFY makers reflected that exports of PFY have reduced obviously.

One company received 5,000-6,000 tons of PFY orders to India in Mar but they almost did not take orders in Apr. Petrochemicals PETPolymer Packaging

Falling PFY exports to India also indicated diminishing textiles orders in India indirectly. Whether this portion of orders were transferred to China or other Southeast Asian countries is hard to be verified.

-Thyssenkrupp Uhde to build a polyester textile plant for Yürek in Turkey

thyssenkrupp Industrial Solutions’ subsidiary Uhde Inventa-Fischer signed a contract to build a new world-scale polymer plant for Yürek Polimer A.S.in Bursa, Turkey. The plant is planned to produce 300 metric tons per day (108,000 tons per year) of PET (polyethylene terephthalate) for low viscosity applications. The PET melt produced by thyssenkrupp technology will then be converted into PET Chips, as well as pre-oriented yarn.Petrochemicals PETPolymer Packaging

Werner Steinauer, CEO of Uhde Inventa-Fischer: “We are very proud that Yürek chose us to build another state-of-the art PET plant.

Our 2R process offers many advantages compared to conventional technologies, such as reduced footprint, less CAPEX, optimized energy consumption and lower production costs.”

Alim Yürek, Member of Board of Directors of Yürek Polimer A.Ş.: “We chose a well-proven technology which could be seamlessly integrated into the further production. With this PET investment, the Yürek group will become an integrated textile group.”

-Polyef continues to implement the project for the production of “green” PET granules

Blagoveshchensk Polyef continues to implement a project to launch the production of “green” PET pellets containing secondary raw materials, the company said.

The enterprise loaded the first pile into the base of the production foundation. It is planned to launch the line in the first half of 2022.Petrochemicals PETPolymer Packaging

It is noted that the production of PET containing recycled resources is an important part of SIBUR’s strategy for sustainable development until 2025. The technology that is planned to be used at Polief is environmentally friendly and belongs to the advanced methods of involving recycled PET in the production cycle.

The “green pellet” produced by Polyef will contain up to 25% recyclable materials and will meet the highest regulatory requirements, meeting the growing market demand for packaging using recycled materials, and will provide its manufacturers with a complete solution that combines both primary and secondary PET. SIBUR also continues research and development work in order to increase the proportion of secondary PET in pellets without losing quality in the future.

-Polykemi Invests in its Own U.S. Compounding Plant

Gastonia, N.C. is the location for Polykemi’s plant which could start production of compounds as early as 2022. Petrochemicals PETPolymer Nonwovenfabric

Sweden’s Polykemi Group AB is investing nearly $12 million to built its own compounding plant in the United States.Petrochemicals PETPolymer Packaging

The investment in the plant in Gastonia, NC, is the largest single investment in the company’s history, and it lays the ground for Polykemi Inc.’s further growth in North America. The 50,000 sq.ft. plant, which is expandable up to 100,000 sq.ft., will initially be equipped with two production lines, and the expected launch of manufacturing is during second quarter 2022.

A family-owned compounder of a broad range of thermoplastic compounds with a strong presence in Europe and Asia, Polykemi began offering its products in North America in 2014 through a cooperative partnership with compounder Omni Plastics, Evansville, Indiana.

-Propylene contract price in Taiwan declines by USD65 per ton in April

The contract price for propylene in Taiwan for April shipments has been negotiated at USD65 per tonne below the previous month, ICIS reported.

According to market sources, agreements between the key producer and its end users were concluded at USD1,015 per tonne, DEL compared to USD1,080 per tonne in March.Petrochemicals PETPolymer Packaging

Earlier it was reported that the contract price of propylene in Taiwan for February shipments was negotiated at USD30 per tonne higher than the previous month.

It was also noted that the contract price of propylene in Europe for April deliveries was finally agreed at EUR1,015 per tonne, which is EUR45 per tonne higher than the level of the previous month, thus marking the fifth month of an upward price trend.

-AMP partners with Greenbridge to increase PET recovery using AI-guided robotic sorting systems

AMP Robotics has deployed six AI-guided robotic sorting systems with Evergreen, one of the nation’s largest recyclers of PET bottles, at its Ohio processing facility.

AMP’s technology identifies and sorts green and clear PET from post-consumer bales of plastic soft drink bottles, which Evergreen recycles into reusable flakes or pellets (rPET) and sells to end markets as feedstock for new containers and packaging.

Products made from rPET can be recycled again—important as states consider legislation around producer responsibility, which charges producers higher rates for hard-to-recycle packaging and could drive packaging design that uses more recycled content. If plastics are not properly separated during the sorting phase, and different materials get processed together, it produces a lower-quality resin, which may not meet manufacturers’ product standards and the stringent requirements for food-grade and beverage containers.Petrochemicals PETPolymer Packaging

-Using chemical recycling to manage end-of-life mattresses

H&S is building its new reactor plant for the recycling of end-of-life mattresses in cooperation with RetourMatras from the Netherlands

H&S Anlagentechnik GmbH has signed a contract with the Dutch recycling company RetourMatras to build a plant for the chemical recycling of discarded PU mattresses.

As of this year, 1.5 million old mattresses are to be dismantled annually by RetourMatras in the Netherlands and Belgium.

A part of these mattresses will be recycled using process technology and know-how provided by H&S, and the Dutch company will supply a fully automated production line for dismantling the old mattresses. The reactor plant is scheduled to be commissioned in the end of 2021. Petrochemicals PETPolymer Packaging

Chemical recycling can be defined as any process by which a polymer is chemically reduced to its original monomer form so that it can eventually be processed (re-polymerized) and remade into new plastic materials that go on to be used in new plastic products.

-SIBUR and TAIF to merge their petrochemical businesses

Today, SIBUR and TAIF have initiated a number of steps to combine their petrochemical businesses. Existing TAIF shareholders will receive a 15% stake in PJSC SIBUR Holding in exchange for the transfer of a controlling interest in TAIF’s group of petrochemical and energy companies.

The remaining stake in JSC TAIF can be subsequently purchased by the combined company.Petrochemicals PETPolymer Packaging

The deal will be closed subject to completion of the relevant corporate procedures and receipt of necessary regulatory approvals.

This combination will make the new company’s petrochemical operations more competitive in the global market, improve its resilience to market fluctuations, and also unlock further growth potential of Russia’s petrochemical industry through joint realization of capital intensive projects, and also boost chemical non-commodity exports. The transaction will also bring new jobs and opportunities for sustainable development and environmental management. Furthermore, the new combined company will benefit from improved resource base diversification, distribution and logistics optimisation, joint R&D development, and sharing operational best practices to maximize the efficiency of its assets. Upon realization of SIBUR’s and TAIF’s already approved investment projects, the combined company will be one of the world’s top 5 producers of polyolefin and rubber products.

-Business groups vow to aggressively expand green economy programs

Philippine business groups will prioritize the expansion of “green” economy interventions to ensure environment-friendly operations and sustainable economic recovery from the raging health and economic crisis.

“The interconnected challenges in public health, the economy, and the environment cannot be ignored. Petrochemicals PETPolymer Packaging

These have greatly disrupted global economic growth and punctuates the urgency to rebuild a more sustainable and resilient future,” said Prof. Dindo Manhit, President of Stratbase Albert del Rosario Institute (ADRi) during their recently held virtual online forum on the theme “Moving Towards A Sustainable Future Through ESG” organized in partnership with environmental advocacy group Philippine Business for Environmental Stewardship (PBEST).

“We believe that the private sector, through ESG, plays a vital role in advancing the country’s sustainable development,” Manhit said.

Metro Pacific Investments Corporation Chief Finance Officer and Chief Sustainability Officer Ms. June Cheryl Cabal-Revilla said, “We’ve put sustainability pillars across the businesses which include exceptional service, operational efficiency, environmental stewardship, human capital excellence, positive community impact, and governance and business ethics. We’ve also put our focus on progress by enabling genuine progress and development.

Petrochemicals PETPolymer Packagingrecycling