Petrochemicals Plastic Sorters 09-09-2021 - Arhive

Petrochemicals Plastic Sorters

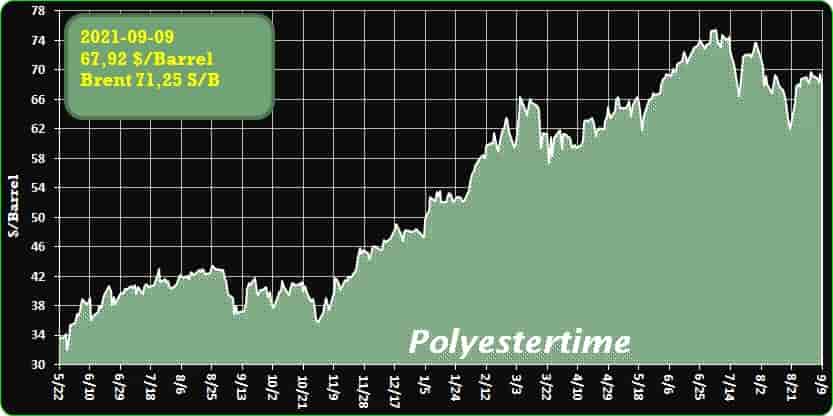

Crude Oil Prices Trend

-Artificially intelligent robotic sorters are the future of data-driven recycling

Artificially intelligent robotic sorting technology is the future of centralized, data-driven recycling models. Generally paired with optical sorting technology for the best results, the latest robotic sorters are achieving (and starting to exceed) 70 picks per minute for mixed plastics and paper. They are also being used very effectively for C&D sorting, and they have great potential for other materials including metals, electronics, organics and glass. With contamination of end product being a number one concern for MRF operators due to rapidly changing, highly contaminated incoming streams on the one side, and shrunken global end markets such as China, coupled with underdeveloped domestic markets for many recovered materials, getting to the high purity levels required by today’s end markets is among the most significant challenges recyclers face.

The use of artificially intelligent (AI) robotic sorting technology increases yield and recovery rates and improves quality of materials recovered – increasing its ability to compete with virgin product on the market.

-Portugal: approved ban on some single-use plastic from November

Portugal’s government has approved legislation banning from 1 November the sale of certain single-use plastic products, such as cotton swabs, cutlery, plates, straws and sticks for balloons, said Macaubusiness. Petrochemicals Plastic Sorters

In a news released, the Ministry of the Environment and Climate Action said that the law, which was approved at Thursday’s weekly cabinet meeting, represents “the partial transposition” of a European Union directive approved on 5 June 2019 on “reducing the impact of single-use plastic products [and] products made of oxodegradable plastic.”

According to the notice, as of 1 November “the placing on the market of certain single-use plastic products such as cotton swabs, cutlery, plates, straws, balloon sticks, as well as cups and food containers made of expanded polystyrene is prohibited.”

In line with the EU directive, the government legislation sets two targets for the reduction of consumption of cups for drinks and packages for ready-to-eat food: an 80% decrease in consumption from the 2022 level by the end of 2026, and a 90% decrease by 2030.

These costs for plastic produced in 2040 will rise to US$7.1 trillion unless urgent action is taken Petrochemicals Plastic Sorters

The lifetime cost to society, the environment and the economy of plastic produced in 2019 alone has been revealed at US$3.7 trillion,¹ more than the GDP of India according to a new report by Dalberg commissioned by WWF. Unless action is taken, these costs are set to double for the plastics produced in 2040 at US$7.1 trillion², equivalent to 85% of global spending on health in 2018 and greater than the GDP of Germany, Canada, and Australia in 2019 combined. The report demonstrates that governments and citizens are unknowingly subsidizing a plastic system that is imposing countless negative impacts on people and the environment.

The report “Plastics: The cost to society, environment and the economy” highlights how fragmented regulatory approaches,misplaced incentives as well as lack of coordinated technical resources, financial support and consistent data on plastic leakage are currently costing us the Earth. Failure to understand and remediate the real costs of plastic will cost even more in the future, as under a business as usual scenario it is estimated that by 2040 there will be a doubling of plastic production and a tripling of plastic pollution entering the ocean to 29 million tonnes, increasing the total stock of plastic in the ocean to 600 million tonnes. Greenhouse gas (GHG) emissions from the plastic lifecycle will account for up to 20% of the entire global carbon budget, accelerating the climate crisis.

-What does science say about fracking?

Researchers question why Australia is still pursuing fracking despite risks to human health and the environment.

The federal government recently awarded $50 million in grants to private energy companies to fund the exploratory drilling of the Beetaloo Basin, as part of its heavily criticised “gas-led recovery”. Petrochemicals Plastic Sorters

The 28,000 square kilometre Beetaloo region begins about 500 kilometres southeast of Darwin in the NT. The region, which includes Aboriginal lands and pastoral leases, is estimated to contain significant fossil fuel resources, including shale gas and shale oil.

Man standing in front of a gate with a sign saying “NO FRACKING, NO NEGOTIATION”

Rod Dunbar, Nutwood Downs Station, NT. Credit: Lock the Gate Alliance.

But traditional owners have not given permission for fracking on their land and staunchly oppose it. Community members and pastoralists also continue to raise concerns about the health and environmental effects, and researchers question the decision to pursue new fossil fuel resources in the face of the climate emergency.

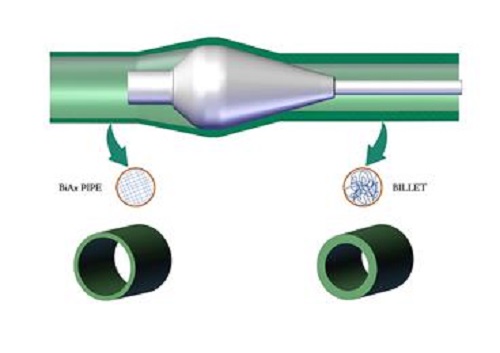

SITTARD, THE NETHERLANDS, September 7, 2021 – SABIC, a global leader in the chemical industry, today has announced the development of a new technology and range of dedicated polyethylene (PE) and polypropylene (PP) resins that mark a significant leap forward in the performance profile of polyolefin pressure pipes.

Together with Tecnomatic and aquatherm, two major specialists in pipe manufacturing, the technology is being advanced from concept to reality.

As ‘Golden Sponsor’ of the International Plastic Pipes XX (PPXX) Conference and Exhibition (6-8 September 2021) in Amsterdam, SABIC introduced the new concept during the conference and presented the technology in the PPXX Technical Sessions.

Petrochemicals Plastic Sorters

-Lenzing signs up to UK environmental initiative

Austrian fibre manufacturer Lenzing Group has joined WRAP’s Textiles 2030 voluntary agreement, the ten-year environmental programme for clothing and textiles.

The initiative has set itself a number of goals including halving carbon emissions by 2030, in line with the Paris Agreement, achieving net zero by 2050, and reducing the aggregate water footprint of new products sold by 30 per cent.

“As leaders in innovation, Lenzing are a partner of global textile and nonwoven manufacturers and drive many new technological developments. Having launched the pioneering Refibra technology in 2017 to contribute to the circular economy within the textile industry and proudly manufacturing in the United Kingdom, the Lenzing Group is honoured to take part in this initiative to accelerate circularity,” the firm said. Petrochemicals Plastic Sorters

Since its launch in April, Textiles 2030 has welcomed major brands and retailers, academic institutes, re-use and recycling organisations and 20 other affiliates.

-Total Corbion PLA marks 100kT Luminy PLA production milestone

Total Corbion PLA

Total Corbion PLA’s plant in Rayong Thailand has, since its grand opening in 2019, earlier this summer reached a cumulative production volume of 100kT of Luminy® PLA. The plant is now running at name plate capacity of 75kT annually in order to meet the evergrowing demand for PLA bioplastics. Petrochemicals Plastic Sorters

Luminy® PLA resins are biobased and made from annually renewable resources, offering a reduced carbon footprint versus many traditional plastics. At the end of their useful life, PLA products can be mechanically or chemically recycled. The biodegradable and compostable functionalities of PLA make it the material of choice for a wide range of markets and applications, including fresh fruit packaging, food serviceware, durable consumer goods, toys and 3D printing. Luminy® PLA can be a more sustainable alternative to established oil-based plastics that might not have as many end-of-life avenues available to them and many producers are making the switch to bioplastics for this reason.

-Polyplastics Co., decided to construct the new polymerization plant in Taiwan

Polyplastics Co., Ltd. has decided to construct the new polymerization plant with the production capacity of 5,000 tonnes per year at Polyplastics Taiwan Co., Ltd., said the company.

As a highly heat-resistant super engineering plastic, LCP is used in a wide range of industrial fields, mainly electronic components used in information and communication equipment such as personal computers and smartphones, and its market has continued to expand at a high growth rate. In recent years, the market demand has increased along with the increase in investment for 5G equipment, and it is expected that the applications of LCP will continue to expand with the full-scale support for 5G millimeter waves. Petrochemicals Plastic Sorters

We have the LCP polymerization plant with the production capacity of 15,000 tons/y at the Fuji Plant (Fuji City, Shizuoka Prefecture), and PTW has been responsible for the compounding process in the manufacturing of LCP products. This new polymerization plant enables PTW to have the integrated production of LCP products from polymerization to compounding and LCP polymerization. In the future, by expanding PTW’s LCP polymerization plant, the Polyplastics Group as a whole will achieve the production capacity of 25,000 tons/y of LCP polymerization.

AIM, the European Brands Association and the Alliance to End Plastic Waste have entered a partnership to drive the next stage of development for intelligent waste sorting under the Digital Watermarks Initiative HolyGrail 2.0. They will work with the City of Copenhagen to conduct the semi-industrial test phase of the pilot.

With this milestone, developers move one step closer to precision identification and sorting of plastic packaging waste through digital watermarks, with the potential to revolutionize the sorting and recycling process of plastic packaging.

Over the next four months, a prototype sorting detection unit will be installed at the Amager Resource Centre (ARC) in Copenhagen, where the trials and demonstrations with around 125.000 pieces of packaging representing up to 260 different stock-keeping units (SKUs) will be held. Petrochemicals Plastic Sorters

Engineers will test for several parameters including the speed and accuracy of the system, to ensure its ability to withstand the pressures of full-scale industrial operations. If successful, digitally watermarked products could be introduced to store shelves in Denmark, France and Germany by the first half of 2022 for in-market demonstrations and industrial-scale trials.

-PetroChina Liaoyang to start up new HDPE plant in China

PetroChina Liaoyang Petrochemical, part of the Chinese petrochemical major – PetroChina, in which CNPC owns 80% of shares, is in plans to start up new high density polyethylene (HDPE) plant in Liaoyang, China, in September, 2021, according to CommoPlast with referemce to market sources. Petrochemicals Plastic Sorters

The new plant will have a capacity of 400,000 mt/year of HDPE.

As MRC reported earlier, PetroChina Liaoyang Petrochemical successfully started up its new polypropylene (PP) plant in late August. Based in Liaoning City, Liaoyang Province, China, the new PP plant has a production capacity of 300,000 tons/year. Tthe construction of a new PP plant in Liaoning began in September, 2019, and was completed in early June, 2021.

Petrochemicals Plastic Sorters