Petrochemicals Polyethylene PVC 12-08-2021 - Arhive

Petrochemicals Polyethylene PVC

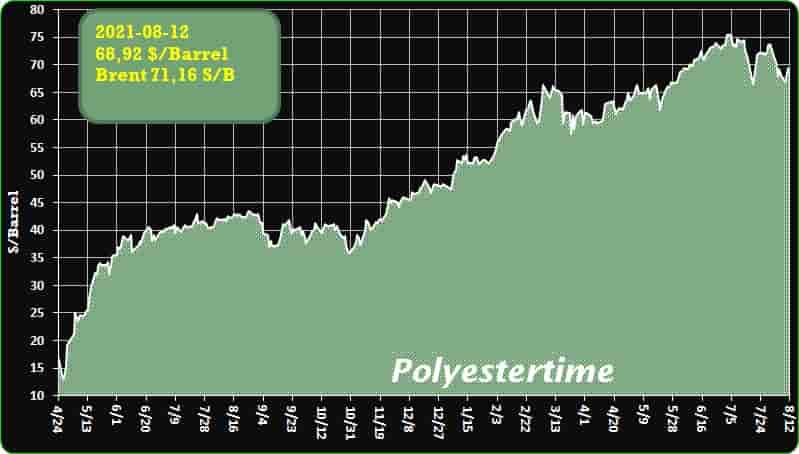

Crude Oil Prices Trend

-NILIT® Unveils “Making Nylon Sustainable,” The Company’s Corporate Sustainability Report

NILIT, the global supplier of high-quality Nylon 6.6 for apparel, and owner of the SENSIL® sustainable brand, is proud to announce the publication of its sustainability report covering the period 2017-2020. The document, entitled “Making Nylon Sustainable,” details the company’s significant achievements to improve its environmental footprint as well as its plans to positively influence the textile and apparel industry to choose more sustainable products and use them in more responsible ways.

“Sustainability is a core value at NILIT,” says Ilan Melamed, General Manager. “We are dedicated to providing the most consumer-relevant, highest quality, and most sustainable premium Nylon 6.6 products to the apparel market. To attain this goal, we continually invest in operations and product development, leveraging our partnerships throughout the supply chain. ‘Making Nylon Sustainable’ captures our vision and our commitment to environmental and social responsibility, and we are very pleased to make this public statement.”

-Petkim Raises August LDPE Selling Prices in Turkey Again

Turkish polymer producer Petkim, whose controlling stake is Azerbaijani SOCAR, has raised its August selling prices for high-pressure polyethylene (LDPE) again, market sources told ICIS .

So, according to them, on August 5, the company increased the price of LDPE by USD50 per ton, FCA Aliaga.

Petkim has already raised LDPE prices by USD150 per ton earlier this month .

The actual prices quoted by the company are on a gross basis, and Petkim may provide large discounts on shipments. Petrochemicals Polyethylene PVC

Delays in the arrival of import volumes and low levels of material stocks appear to be the main drivers of price increases.

As reported by MRC, Petkim’s net profit amounted to 891.757 million Turkish lira (TL) in the first quarter of 2021 against a net loss for the same period last year in the amount of TL 9.781 million.

-Teknor Apex acquires Dorum Color’s dry colour business

Akron, Ohio-based Dorum Color focuses on the rotational molding market.

Global compounder Teknor Apex Co. has acquired the dry colour business of Dorum Color Co., a material supplier that focuses on the rotational molding market.

The financial terms of the deal, which is structured as an asset purchase, have not been disclosed. Petrochemicals Polyethylene PVC

Customers will be supplied from Teknor’s Henderson, Kentucky facility, Teknor officials said in a news release.

“Dorum Color’s focus on superior quality and delivery performance aligns directly with our approach,” said Teknor president Suresh Swaminathan.

Headquartered in Akron, Ohio, Dorum Color has founded by Scotty Dority in 1998. Described as an expert in the rotomolding industry, Dority had previously worked for Teknor Color, a subsidiary of Teknor Apex Co., in Ohio.

-India’s real GDP growth to be 20% YoY in Q1 FY22: Motilal Oswal10

India’s real gross domestic product (GDP) is expected to grow by 20 per cent on a year-on-year (YoY) basis in the first quarter of this fiscal, according to Motilal Oswal Financial Services (MOFS), which recently said in a report that the ‘economic activity index’ (EAI) for India’s real gross valued added (GVA) grew by 11.6 per cent YoY in June after growing by 22.8 per cent YoY in May.

“It implies EAI-GVA growth of 22.6 per cent YoY in Q1 FY22, following a contraction of 14.4 per cent YoY in Q1 FY21. A low base led to higher double-digit growth in the non-farm sector, while farm activity grew 6.6 per cent in the quarter,” MOFS’ EcoScope report said. Petrochemicals Polyethylene PVC

“The estimates suggest that India’s real GDP growth was 20 per cent YoY in 1QFY22, which is in line with our expectations,” it asserted.

Notwithstanding the double-digit growth in Q1 in this fiscal, the real GDP growth would slow towards 5-7 per cent in the remaining quarters.

“The way EAI-GVA, EAI-GDP was also supported largely by a low base. Although EAI-GDP grew by a modest 3.6 per cent YoY in June as against 11.6 per cent YoY in May, it increased by 23 per cent YoY in Q1 FY22 as against a contraction of 21.2 per cent YoY in Q1 FY21,” it said.

-Reliance Raises August PVC Prices in India

Reliance Industries Ltd (RIL), an Indian energy and petrochemical giant and the largest polyvinyl chloride (PVC) producer in the country, has raised its August PVC bid for the Indian market amid strong demand for the material, a source told ICIS . close to the company. Petrochemicals Polyethylene PVC

So, since August 6, the company’s PVC price proposals have been raised by 1.5 per kg Indian rupees (Rs) and are at the level of Rs120.5-122 per kg, EXW (ex-works), which is equivalent to prices in the range of USD1 365-1 370 per tonne, CFR India, at USD1 = Rs74.70.

Restocking activities in India intensified on the back of relatively low import volumes in June-July, which contributed to the increase in demand.

Prior to that, Relianceincreased PVC prices on July 16 this year also by Rs1.5 per kg – to the level of Rs119-120.5 per kg, EXW, against the background of increased demand for the material.

It was previously noted that the RIL PVC plant in Dahei (Dahej, India) returned to work on May 5 after preventive maintenance.

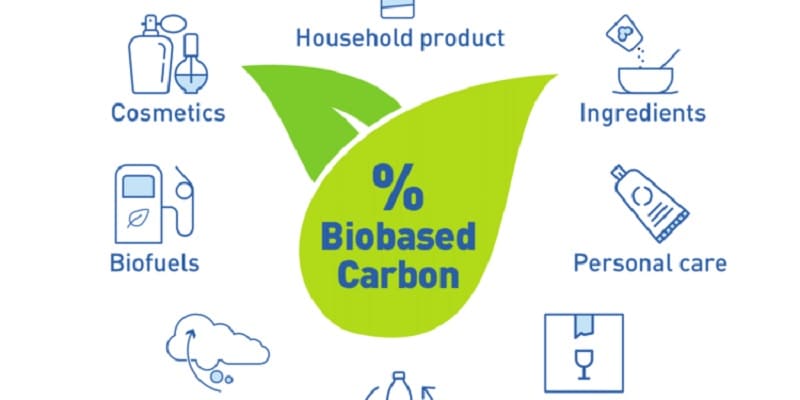

-Bio-based Testing For Renewable Plastics

Plastic. It’s been the buzzword at the heart of waste reduction strategies for years, with regulations around the world working to reduce production, use and disposal of the material in both domestic and industrial settings. As well as limiting the amount of plastic we produce, there has arisen a new demand – to change the way we produce it. This need has been accelerated by the EU’s sales ban on single-use plastics announced in July this year, pushing manufacturers to find sustainable alternatives. Petrochemicals Polyethylene PVC

While plastics are traditionally derived from fossil fuel-based materials such as oil or natural gas, a new market for bio-based products has emerged. In comparison to their traditional petroleum-based counterparts, biobased products, which are derived from organic materials that are available on a renewable basis, have been gaining increased industry interest in recent years. Intended to facilitate the circular economy, these products are often made from materials such as sugarcane, corn, or cellulose. While they may seem something of a golden ticket to our plastic problem, concerns have been raised over whether these solutions are truly best for our environment. Companies have therefore been working hard to not only produce these alternatives but to demonstrate their environmental benefit.

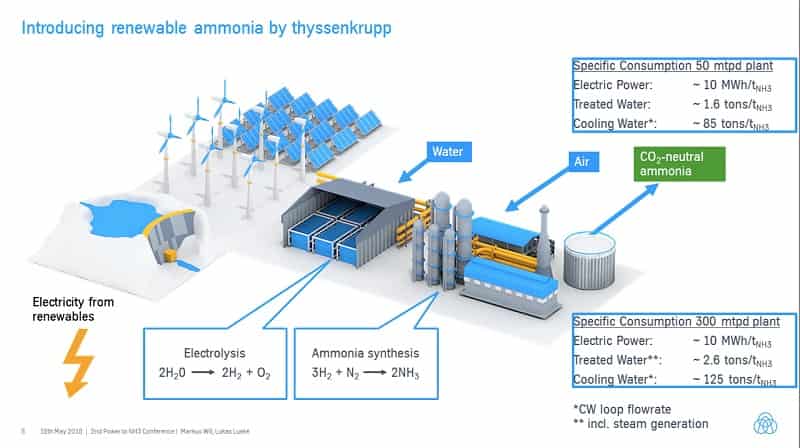

-thyssenkrupp to perform technical study for new green hydrogen and green ammonia project

thyssenkrupp has been awarded a contract to perform a technical study for a new green hydrogen and green ammonia project by the Emirati company Helios. A water electrolysis plant as well as a facility for sustainable ammonia production are planned to be constructed at Kizad in Abu Dhabi, UAE, based on thyssenkrupp technology. It will be the first commercial plant to produce CO2-free green ammonia from renewable resources in the UAE. Petrochemicals Polyethylene PVC

The planned facility will integrate thyssenkrupp’s green hydrogen and green ammonia technologies with the first phase set to incorporate a multi-megawatt electrolyzer plant and an ammonia production facility with capacity of 20,000 tonnes per annum with next step to increase this to 200,000 tonnes per annum.

- K. Saiyed, Managing Director of Helios: “This project is another important milestone for in the UAE’s shift to a lower carbon renewable energy future. The new facility will produce green ammonia which is an energy carrier that enables easy transportation of renewable energy e.g. via ship. It can also be used as emission-free transport fuel and in the fertiliser and chemical industries.”

-PP production in China increased by 20.6% in July

The volume of polypropylene (PP) production in the Chinese market grew by 20.6% in July this year compared to the same period last year, ICIS reported.

At the same time, compared to June 2021 (2.26 million tonnes), the July PP production in the country, which amounted to 2.35 million tonnes, showed an increase of 4.1%. Petrochemicals Polyethylene PVC

Earlier it was noted that PP output in China increased by 13% in 2020 compared to the same indicator a year earlier and amounted to 2.16 million tons.

-Additive Enables Plastics to Decompose Microplastics-Free

Food-safe packaging without an environmental downside: plastics manufactured with the additive feature a custom stall period that delays the onset of decomposition if not recycled.

Australia-based Twelve8 Technology has launched a plastics additive that enables polymers blended with it to decompose naturally, without industrial treatment, within two years. The PaktoEarth RAWS-tech additive decomposes to water, carbon dioxide (CO2), and less than 1% biomass. Petrochemicals Polyethylene PVC

The additive-blended plastic, which is suitable for food packaging, can be recycled. But for post-consumer plastic that “escapes” the recycling process, ending up in nature or landfill, the technology offers an accelerated end of life vs. conventional plastics, which may take hundreds of years to degrade.

“Plastic is a massive threat to our environment. Recycling is a must but not always possible and not always achieved — 84% of plastic waste in Australia ends up in landfill,” Anthony Harrison, CEO, Twelve8 Technology, tells PlasticsToday. “We’re like eco-insurance that takes care of escaped plastic whilst alternatives are found.”

Twelve8 has distribution rights to the additive technology, which was developed at the Nano and Advanced Materials Institute (NAMI) in Hong Kong.

-Tesla Impact Report Highlights Sustainability & Battery Recycling

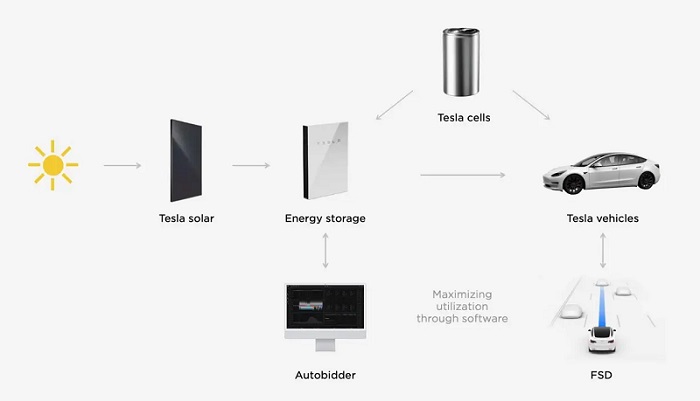

The latest Impact Report from Tesla says the company is making sustainability a central part of all its business operations.

In its 2020 Impact Report, Tesla says, “In 2020, Tesla customers helped accelerate the world’s transition to sustainable energy by avoiding 5.0 million metric tons of CO2e emissions.” The company’s focus is on more than building electric vehicles. Here’s what Tesla has to say about its mission:

“We are designing and manufacturing a complete energy and transportation ecosystem that is fully vertically integrated. By doing so, we are creating affordable products that work together to amplify their impact, leading to the greatest environmental benefit possible. We seek to achieve this through our research and software development efforts as well as through our continued drive to develop advanced manufacturing capabilities.” Petrochemicals Polyethylene PVC

Petrochemicals Polyethylene PVC