Petrochemicals Polymer DioxideTitanium 07-10-2020 - Arhive

Petrochemicals Polymer DioxideTitanium

Crude Oil Prices Trend

-FINEX™ Reaches New Milestones; Launches Officially at Intertextile Shanghai Apparel Fabrics

As part of its efforts to promote textile fibre recycling in China, Sateri is in dialogue with the China Association of Circular Economy (CACE)

FINEX™, Sateri’s marquee brand for recycled fibre, is now certified to the Recycled Claim Standard (RCS) which provides verification of recycled raw materials through the supply chain.

RCS is intended for use with any product that contains at least 5% recycled material. Sateri has successfully produced FINEX™ viscose fibres with up to 20% recycled content. Under the RCS certification process, each stage of production is required to be certified, beginning at the recycling stage and ending at the last seller in the final business-to-business transaction.

These new developments were announced at the official launch of FINEX™ today. About 160 guests, mostly senior representatives of major fashion brands and fabric and garment makers, gathered to celebrate the milestones that cement the status of FINEX™ as a game changer for sustainable fashion.

Made from upcycled sugarcane waste, the ‘fully compostable’ offering can be used for greasy, wet, or hot food. FoodNavigator speaks to W-Cycle co-founder Joseph Siani to find out more.Petrochemicals Polymer DioxideTitanium

Israeli foodtech start-up W-Cycle is concerned about plastic pollution, with an estimated 8m tonnes entering the marine environment every year.

At the same time, food waste is a growing concern. Upcycling food chain by-products, such as discarded seed husks and crop pulp, presents an opportunity for industry – and one that Israeli start-up W-Cycle is seizing with both hands.

The foodtech business has developed plastic-free packaging made from upcycled sugarcane waste, which W-Cycle co-founder and CTO Joseph Siani said will help consumers ‘ditch plastic containers’ and ‘create a cleaner environment’.

Upcycling sugarcane waste

The key to W-Cycle’s innovation comes from the sugarcane industry. The crop is predominantly grown in tropical countries as both a food and fuel source.

Polyplex (Thailand) Public Limited Company (PTL), a subsidiary of Polyplex Corporation Limited (PCL; Gautam Buddh Nagar, India), will invest USD102.8 million to build a biaxially oriented polyethylene terephthalate (BOPET) thin film line at Decatur, Alabama.

The production capacity of the planned plant will be 50,000 metric tons/year, said Chemweek. Petrochemicals Polymer DioxideTitanium

The company also intends to debottleneck the polyethylene terephthalate (PET) resin plant at Decatur, to raise the capacity from the current 58,000 metric tons/year to 86,000 metric tons/year. The project is expected to be commissioned in 24 months.

-China September chemicals buoyed by firm demand, supply pressure

China’s chemical markets in September were generally buoyed up by firm demand due to pre-holiday restocking and tight supply for some products.

Twenty of the 33 petrochemicals tracked by the ICIS China team had price increases in September from August, eight of which rose by more than 10% with the strongest growth logged by propylene oxide (PO) at 37%. Petrochemicals Polymer DioxideTitanium

Thirteen products posted price declines, five of which had more than a 5% slump.

PO is included in the 17 products that comprise the ICIS China Petrochemical Index.

To regular participants in the Europe polyethylene terephthalate (PET) market, it will come as no surprise that there have been a host of unexpected occurrences, which have sent PET off on a tangent going into the fourth quarter.

Food, beverage and now hand sanitizer markets are reliant on PET packaging, making it an essential product in daily life. Petrochemicals Polymer DioxideTitanium

A global pandemic challenged this concept, but PET weathered the storm better than many other products. Yet its impact, coupled with macroeconomic and geopolitical uncertainties, continues to challenge the PET value chain.

The end of the summer also marks the end of the traditional high season for PET. Expectations had been for the market to then plateau.

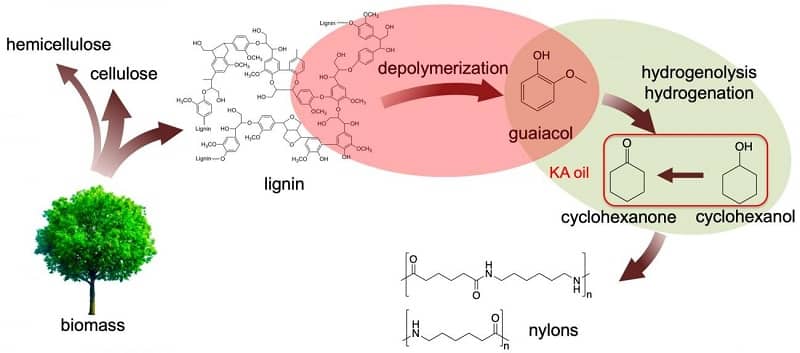

-Converting Paper Manufacturing Waste Into Valuable Chemicals : Ames Laboratory Research

Two-step procedure of waste Kraft-lignin conversion to valuable nylon precursors in an ambient environment Petrochemicals Polymer DioxideTitanium

A researcher team from Ames Laboratory, U.S. Department of Energy, has discovered a way to generate valuable chemical precursors involved in nylon making from a common byproduct of the process of paper manufacturing. In terms of the energy input and the solvents used, this process is environmentally friendly compared to other methods and provides an alternative to the burning of pulping waste products.

Annually, the paper industry generates Kraft (from the German meaning strength) lignin, a major waste product, that amounts to about 50 million tons. The waste lignin can be burnt for heat, but the burning generates greenhouse gases, i.e. releases carbon dioxide in the atmosphere.

Researchers at Ames Laboratory discovered that treating the waste lignin at a reasonable temperature (200 °C) with aqueous sodium hydroxide produces guaiacol. With the help of suitable catalysts, under even milder conditions, the Guaiacol can then be converted to nylon precursors-with this new, two-step viable process that produces a useful chemical from the waste lignin.

-EU at risk of missing plastic recycling targets

The European Union is facing a growing waste problem and is at risk of missing its plastic recycling targets for 2025 and 2030 as more stringent export rules will be implemented next year, the bloc’s independent auditor warned Tuesday.

As part of its plastics strategy adopted in 2018, the European Commission set itself the goal that at least 50% of all plastic packaging waste will be recycled by 2025, and to reach 55% by 2030. Petrochemicals Polymer DioxideTitanium

The EU’s executive arm also wants to ensure that all plastic packaging on the EU market will be either reusable or recyclable by 2030.

-CarbonLite: Inside the World’s Largest Plastic Bottle Recycling Plant

CarbonLite is the world’s largest “bottle-to-bottle” plastic recycling plant in Riverside, Calif.

“SoCal Connected” takes a look inside the state-of-the-art facility where billions of plastic bottles are churned on an annual basis. Petrochemicals Polymer DioxideTitanium

The process involves transforming old plastic bottles into PET pellets and flakes in order to produce new plastic bottles.

The bottles are required to go through metal detectors, a special “prewash” phase, and a label-removing facility before they can become shiny, brand new pellets.

Thanks to the latest applications of TOMRA Sorting Recycling’s sensor-based flake sorting solutions, customers are now able to achieve unparalleled recovery and purity rates of polyethylene (PE) and polypropylene (PP), both of which are polyolefins (PO). Until now, the company’s flake sorting solutions mainly focused on polyethylene terephthalate (PET).

The two optical flake sorting solutions – the company’s new INNOSORT FLAKE unit and an AUTOSORT® FLAKE – form part of TOMRA’s Symphony of all Sorts concept whereby TOMRA Sorting Recycling’s latest generation AUTOSORT® and its complementary products work together to create a perfectly harmonised symphony to sort all kinds of waste at advanced levels of accuracy and sophistication.

Together the new INNOSORT FLAKE and AUTOSORT® FLAKE add the ‘Sounds of pure flakes’ to TOMRA’s Symphony. Petrochemicals Polymer DioxideTitanium

-EU-funded project reports success with food packaging bioplastics projects

The EU-funded REFUCOAT project has successfully developed a new set of processes for producing bioplastics for food packaging from renewable materials, with the aim of replacing traditional fossil-based raw materials. Petrochemicals Polymer DioxideTitanium

Using these bioplastics, which include polyhydroxyalkanoates (PHA) and polyglycolic acid (PGA), REFUCOAT has developed three different bio-based active packaging systems, designed specifically for fresh chicken, breadcrumbs, and crisps.

A key innovation has been the development of coatings based on bacteriophages which significantly slow down the growth of Samonella bacteria in chicken samples packed in modified atmosphere packaging (MAP) chicken breast samples.

Petrochemicals Polymer DioxideTitanium

Petrochemicals PET DioxideTitanium 06-10-2020