Petrochemicals Polymer Film 13-08-2021 - Arhive

Petrochemicals Polymer Film

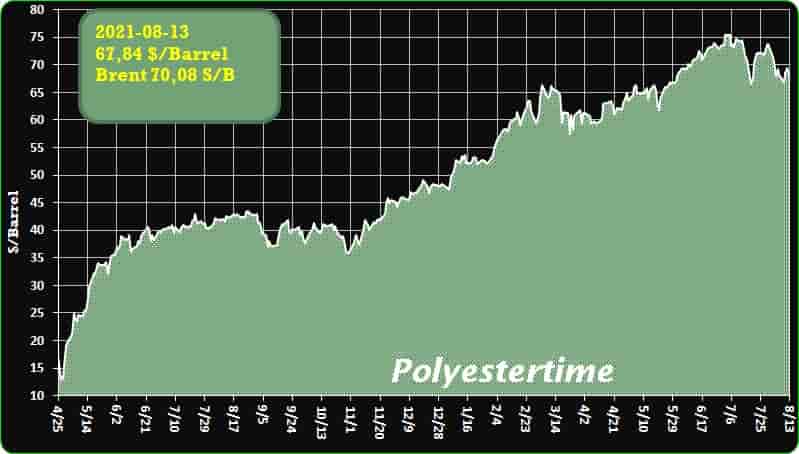

Crude Oil Prices Trend

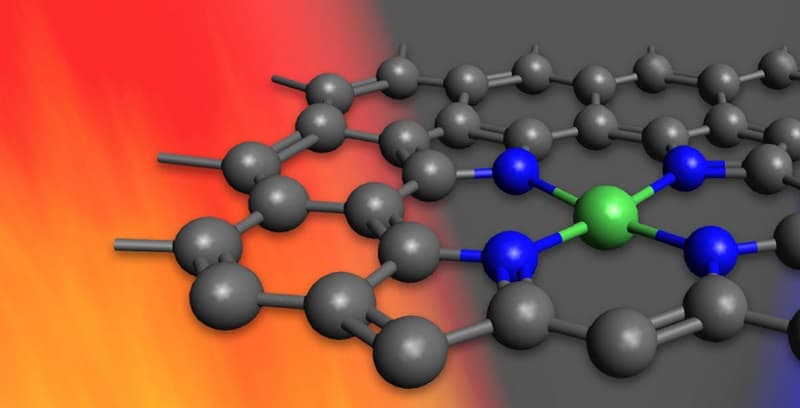

Their work aims to bridge two approaches to driving the reaction – one powered by heat, the other by electricity – with the goal of discovering more efficient and sustainable ways to convert carbon dioxide into useful products.

Virtually all chemical and fuel production relies on catalysts, which accelerate chemical reactions without being consumed in the process. Most of these reactions take place in huge reactor vessels and may require high temperatures and pressures.

Scientists have been working on alternative ways to drive these reactions with electricity, rather than heat. This could potentially allow cheap, efficient, distributed manufacturing powered by renewable sources of electricity.

But researchers who specialize in these two approaches – heat versus electricity – tend to work independently, developing different types of catalysts tailored to their specific reaction environments.

Pact Group and Cleanaway announced the creation of a new plastic recycling facility at Laverton, Victoria.

This facility will become Australia’s largest post-consumer polyethylene recycling plant converting locally collected kerbside materials into high quality food grade rHDPE and rPP resin. Petrochemicals Polymer Film

This will facilitate the inclusion of locally processed recycled resin into food, dairy and other packaging, enabling brand owners and retailers to deliver on their sustainability objectives.

This state of the art facility will process more than 20,000 tonnes or the equivalent of over 500 000 plastic milk bottles and food tubs collected from household recycling bins into food grade resins and will be located at Cleanaway’s recycling facility at Laverton.

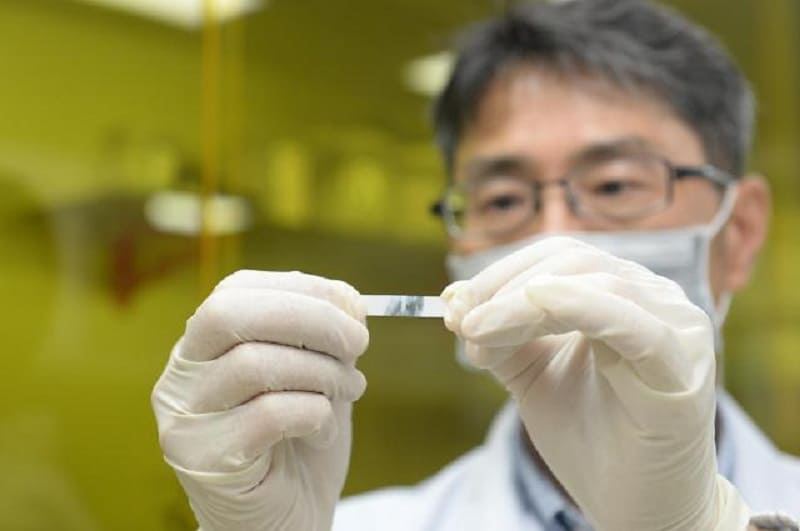

-Researchers develop technology for color-changing chameleon high-polymer film

Researchers have developed a transparent, stretchable high-polymer film material that turns completely white to have zero light transmittance when it is stretched out. The technology can be used for the development of a color-changing “chameleon film.”

There are very few transparent films that can turn white or change their color available. However, such films use nanoparticles or other substances that are reactive to light or impact. They are used to control the brightness of display panels and wearable devices like smartwatches. Many conventional films are made of a photocuring polymer that changes its hardness depending on the strength of luminosity. Petrochemicals Polymer Film

The Electronics and Telecommunications Research Institute (ETRI) said in a statement on August 11 that its researchers have developed a technology that can create the color-changing transparent high-polymer film. The newly-developed film uses light to chemically bond a polymer and a catalyst. Researchers said the technology can be applied to the development of films capable of changing colors like a chameleon.

-A Look at the Plastic Waste Crisis in the Developing World

The Ocean Plastics Leadership Network (OPLN) recently hosted a webinar called “Environmental Intelligence: Deep Diving on the Plastic Waste Crisis in the Developing World” that featured Ian Rosenberger, CEO at First Mile and Day Owl, in conversation with OPLN Founder Dave Ford, two of our speakers from the Waste360 Sustainability Talks event. Petrochemicals Polymer Film

Rosenberger shared how he ended up in the secondary-plastic markets in the developing world. He said that in 2010, around the time of the earthquake in Haiti, he realized he wanted to do something in the global south, and he wanted to be doing meaningful work. Rosenberger ended up spending two years in and around Port-Au-Prince, Haiti in the medical-relief field and came to understand how “we all want the same things — a roof over our heads, the ability to get up and go to work and have a purpose, for our kids to have a better life than we do.” He then came to see it was his job to be a “connector between communities that don’t have a voice and communities that do — and encourage the communities that do to drive resources into communities that don’t.” And, ultimately, “the backdrop to all those conversations and all that time was trash. It’s a defining issue of our time, and I wanted to find a way to connect those things.”

Rosenberger then spoke about how he went through the process of figuring out the best ways to truly help these communities. Through many conversations, he kept hearing that people wanted jobs, not handouts. So, he wanted to create jobs, and “this is the way the business was born.” But, not knowing “anything about anything,” Rosenberger Googled “what can you turn trash into” and came across the idea of fabric. With a few early samples, he then asked brands if they would be interested. Eventually Timberland and others said “yes.” In those first years of First Mile, “We learned a lot about human rights, building human rights frameworks…” And, “We now connect the biggest brands in the world with these communities and remove all of the barriers and risks to those brands engaging with those communities and pulling resources out of it.”

-Twelve8 Technology develops additive that speeds up natural plastic decomposition

An Australian company has created packaging that can break down naturally outside of industrial conditions.

An Australian company has created packaging that can break down naturally outside of industrial conditions. Petrochemicals Polymer Film

Twelve8 Technology has produced an additive that can be mixed with conventional polymers, triggering a degradation of the overall plastic composition within 2 years.

Under natural circumstances, virgin plastics can take anywhere from a several hundred to thousand years to break down into their separate molecular building blocks.

The additive will commence decomposition when activated by sunlight or thermal heat. To prevent too rapid biodegradation, consumers can prefigure the length of a possible delay period. Said period can range from 6 months to 4 years.

-Pandemic makes recycled plastic profitable for first time

Ulster County sees revenue gains as squeezed supply chain drives up demand

Recycling programs cost a lot of money for towns. For citizens, whether you pay for curbside pick-up or drop off your items off at a local facility, it takes time and staff to handle, sort, and resell or rehome your commingled discards. And once your detergent bottles, yogurt lids, and takeout containers are collected, it’s rare that your recyclables will even go on to their next life in the form of a recycled plastic container. Petrochemicals Polymer Film

Recycling just doesn’t work as well as well-intentioned recyclers would think, due to a costly and cumbersome recycling process. “Nationwide the plastic recycling rate is only 8.5 percent,” says Judith Enck, a former EPA regional administrator and current president of Beyond Plastics, a national initiative based at Bennington College that seeks to end plastic pollution.

Very few plastics have a resale market, not all consumers recycle properly and not all municipalities have recycling programs. That means the vast majority of plastics winds up as waste.

-Thai PTTGC Q2 profit surges; petrochemical oversupply risks remain

PTT Global Chemical’s second-quarter net profit surged to Thai baht (Bt) 25bn ($746m) amid improved petrochemical product spreads although worries about global oversupply remain amid the pandemic.

The Thai chemical major’s aromatics business outperformed, with the price spreads of paraxylene (PX) and benzene over feedstock condensate surging in the June quarter from the same period last year. Petrochemicals Polymer Film

The PX-to-condensate spread for the period averaged $283/tonne, up 4% year on year due to seasonal peak demand from the downstream purified terephthalic acid (PTA) and polyester markets in China in April-May, as well as growing demand from the polyethylene terephthalate (PET) resins sector.

“However, there are the number of factors that could pressure the overall PX market, such as the high inventory level of paraxylene inventory, additional supply entering China market in Q3 2021, and the impact of COVID-19 infections,” PTTGC said in a filing on the Stock Exchange of Thailand late on Monday.

Meanwhile, the benzene-condensate spread in the second quarter surged to an average of $393/tonne from $146/tonne in the same period of last year.

For many consumers all over the world, packaged drinking water is indispensable.

Large-volume PET containers offer practical and ecological advantages for household use. Petrochemicals Polymer Film

This is why Krones is expanding the handling spectrum of its stretch blow-moulders.

The Contiform 3 BigBottle is suitable for container volumes of up to eight litres, thus closing a gap in the group’s product portfolio.

For millions of people all over the world, packaged drinking water is an essential part of their daily life, especially if they live in a region where they cannot depend on a reliable supply of potable tap water. Personal, health-related reasons or sensory preferences may also cause consumers to choose packaged alternatives. Whether it is high nitrate values or heavy chlorination: The composition of tap water varies from region to region – and many consumers prefer a water quality different from that coming out of their taps.

-Campaign launched to ‘debunk myths’ of textile recycling

A group of associations have come together to “set the record straight and debunk myths” around the textile recycling industry. Petrochemicals Polymer Film

The campaign, released today (10 August), was launched by the Textile recycling Association , the Bureau of International Recycling, the European Recycling Industries Confederation and the US trade association SMART.

It comes off the back of recent media reports that claimed used clothing can end up being dumped in developing countries (see letsrecycle.com story).

The associations are calling for today’s report to be circulated widely, to “strongly encourage” the world to consume used clothing and textiles.

-KBR awarded ethylene technology contract for olefins complex

KBR has been awarded a technology licensing contract by Hyundai Engineering and Técnicas Reunidas for PKN ORLEN’s Petrochemical Development Program in Plock, Poland. Petrochemicals Polymer Film

Under the terms of the contract, KBR will provide technology license, basic engineering design, and proprietary equipment for its leading ethylene technology, Selective Cracking Optimum Recovery (SCORE™), for PKN ORLEN’s Olefins Complex III Project. This is Europe’s largest petrochemical project in 20 years.

“KBR is privileged to be selected as the ethylene technology licensor for this ambitious project and contribute to PKN ORLEN’s growth and sustainability objectives,” said Doug Kelly, KBR President, Technology. “SCORE continues to lead the industry in delivering the highest yields and operational flexibility, while minimizing the carbon footprint.”

Petrochemicals Polymer Film