Petrochemicals Preforms Polyester Filament 30-08-2019 - Arhive

Petrochemicals Preforms Polyester Filament

-Dow to source pyrolysis oil feedstock made from recycled plastic waste

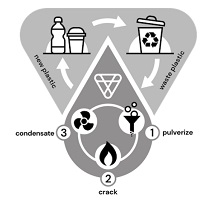

Dow Chemical has reached an agreement with the Fuenix Ecogy Group, based in Weert, The Netherlands, for the supply of pyrolysis oil feedstock, which is made from recycled plastic waste. The feedstock will be used to produce new polymers at Dow’s production facilities at Terneuzen, The Netherlands.

This agreement marks an important step forward to increase feedstock recycling – the process of breaking downmixed waste plastics into their original form to manufacture new virgin polymers.

-RadiciGroup : Sustainability Report has been certified ( Iyalian Language Only)

Accounted the economic, environmental and social performance of 23 companies in the Group of Bergamo.

Certiquality has certified the RadiciGroup 2018 Sustainability Report compliant with the GRI Standards-Core Option model. Petrochemicals Preforms Polyester Filament

The Report reports the economic, environmental and social performance of 23 Group companies in the various countries in which they operate.

-Bottle closures tethered for convenience, recycling

The first cross-license registered intellectual property exchange between Nippon Closures Co., Ltd. (Tokyo) and AptarGroup, Inc. (Crystal Lake, IL) is for tethered beverage closures, an arrangement that the companies intend to expand into other areas as well.Aptar Tethered Closures Combo

This first partnership proposes to continuously improve the consumer drinking experience while also creating solutions for beverage closures that are better for the environment starting with these two:

- Flip Lid (green closure) by Aptar is a consumer-friendly dispensing closure designed to promote post-use recycling as the closure remains together with the bottle throughout its lifecycle, making it more likely to be collected and sent through the recycling stream with the container.

-Formosa Plastics announces $332 million expansion

Louisiana Gov. John Bel Edwards and Formosa Plastics Corp. (FPC) Plant Manager Paul Heurtevant jointly announced the company will invest $332 million to expand its production of PVC resin. Formosa Plastics also will add production equipment in two other units of the company’s Baton Rouge manufacturing facility, which FPC has operated since 1981. Petrochemicals Preforms Polyester Filament

The project will create 15 new direct jobs with an average annual salary of $77,667, plus benefits. Louisiana Economic Development (LED) estimates the project will result in 66 new indirect jobs, for a total of 81 new jobs in East Baton Rouge Parish and the Capital region.

-Eastman Chemical (EMN) to Unveil Sustainable Fabric Collection

Eastman Chemical Company EMN is slated to introduce its new sustainable fabric collection at the international fashion and textile exposition, Premiere Vision-Paris, which will be held from Sep 17-19.

Eastman Chemical is the maker of sustainably sourced Naia cellulosic yarn. The company offers feasible eco-conscious materials with Naia for sustainable fashion. The move is in alignment with the industry’s shift toward the circular economy.

The company launched Naia at Premiere Vision in 2018. Since then, it has continued to innovate by establishing two partnerships and creating a new collection of sustainable fabrics.

![]()

-Prada’s latest upcycling initiative takes on ocean pollution

Prada responds to the sustainability challenge with Re-Nylon, its new capsule line of accessories made from recycled materials.

Prada is taking up the challenge to reduce its environmental impact by using ECONYL® regenerated nylon to create luxury goods through its Prada Re-Nylon sustainability initiative. Proposing a renewable, cyclical supply chain that maintains environmental awareness with transparency and accountability, the project crosses five continents, connecting with five upcycling initiatives that turn harmful waste into Prada accessories.

For the third episode in its five-part series, Prada traveled to Mahana Bay, off the coast of New Zealand with Australian actor Alex Fitzalan and Sri Lankan National Geographic explorer and marine biologist Asha de Vos to investigate ghost nets—fishing nets that are abandoned or lost in the ocean—and how they damage the ocean and the wildlife that inhabits it. Petrochemicals Preforms Polyester Filament

-NAPCOR: US lacks recycled PET to meet consumer brands’ pledges

America simply does not have enough recycled PET supply or processing capacity to satisfy commitments being made by brand owners to increase recaptured resin content in their bottles, new data shows.

As program director for the National Association for PET Container Resources, or NAPCOR, Alasdair Carmichael has been looking at the issue for the past year or so.

With a PET recycling rate of a little less than 30 percent in the United States, and much of that material being used for nonbottle applications, NAPCOR said the numbers just don’t add up.

-Karl Mayer launches first three-bar HKS machine at ITMA30

Karl Mayer launched the new HKS 3-M-ON at ITMA 2019, the first three-bar HKS machine with electronic guide bar control, which is linked to the digital world of KM.ON. The HKS 3-M-ON impressed the visitors in Barcelona with its new flexibility and exceptional ease of handling when changing the pattern, and also by its high production rate. Petrochemicals Preforms Polyester Filament

The new machine can reach a maximum speed of 2,900 per min, depending on the working width. This makes it the fastest, high-speed tricot machine with electronic pattern drive that has ever been built. It is also just as fast as the current HKS 3-M model with n-drive, but it is also much more flexible, said Karl Mayer in a press release.

-India generates 9.46 mn tonnes of plastic waste annually

40 per cent of it remains uncollected

India generates 9.46 million tonnes of plastic waste annually, of which 40 per cent remains uncollected and 43 per cent is used for packaging, most of which is single-use, a new study has revealed. Petrochemicals Preforms Polyester Filament

The study has been conducted by Un-Plastic Collective (UPC), a voluntary multi-stakeholder initiative to eliminate plastic pollution in nature and move towards a circular economy.

A study from Fact.MR has found that momentum in the masterbatch industry has been shifting towards special effect masterbatches over the past few years, thanks to their aiding of the overall aesthetics of the products.

With this, the global market for Special Effect Masterbatches is expected to attain a CAGR of over five per cent between 2019 and 2029.

-DASANI to launch new HybridBottle

DASANI has announced it will roll out a next-generation lineup of recyclable, reusable and package-free options.

The range will be anchored by the first-ever HybridBottle in the US made with a mix of up to 50 per cent plant-based, renewable material (PlantBottle) and recycled PET (rPET).

These 20-oz. bottles will launch nationwide in mid-2020 and will include on-pack messaging educating people about HybridBottle technology and encouraging them to recycle. Petrochemicals Preforms Polyester Filament

-Lenzing fibres proved fully biodegradable in water, soil and compost

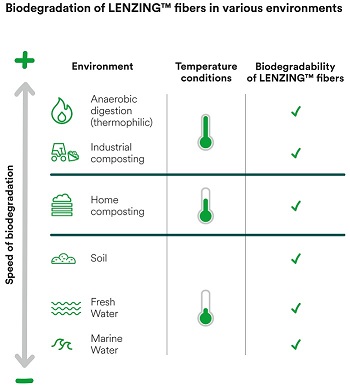

The Lenzing Group has received confirmation of the full biodegradability of its fibres in fresh water by the independent research laboratory Organic Waste Systems (OWS).

The new and existing international certifications conducted by OWS and issued by TÜV Austria also verify that Lenzing Viscose fibres, Lenzing Modal fibres and Lenzing Lyocell fibres are biodegradable in all natural and industrial environments: in the soil, compost as well as in fresh and in marine water

-China MEG demand to pick up in Sept; ’19 start-ups behind schedule

China’s demand for monoethylene glycol (MEG) is expected to pick up in the next two months, with little near-term boost on supply as most domestic plants are running at reduced capacity while 2019 start-ups have lagged behind schedule.

Workers at a garment factory in Huaibei City, Anhui province, east China. (Source: Imagine China/Shutterstock)

The escalating China-US trade war and the slumping Chinese yuan against the US dollar remain as major concerns, particularly for exports of textiles – the key downstream industry of MEG. Petrochemicals Preforms Polyester Filament

September and October are typically the peak consumption months for downstream polyester sector, which is also due to welcome additional capacities in the months ahead.

-New laser printing method creates smart fabrics in minutes

RMIT University had just developed a new, easy-to-scale, and cost-efficient way to manufacture smart fabrics, specifically textiles that can be directly embedded with energy storage media for use with current mobile devices.

The smart fabrics industry, though relatively new in terms of widescale application, has been growing significantly over the past few decades. E-textiles, as they are officially categorized, range from simple fashionable accessories with added technological flair, to practical ones that can be integrated with the user’s set of electronic gadgets and devices. Health-monitoring sensors, for example, are of particular importance in the e-textile industry, as prevention is often the better option in medical care, especially if the medium is easy to put on the body in a non-invasive, almost natural way.

-Renmatix’s latest developments in plant material conversions

Mike, can you just briefly introduce Renmatix?

Renmatix is a Pennsylvania-based company that has developed the Plantrose Process, which converts plant materials into valuable, multifunctional, clean ingredients for a wide range of applications, including food and personal care.

Winner of the 20th anniversary Presidential Green Chemistry Award, the proprietary process challenges conventional production economics by using only water in converting plant-based feedstocks into high performing, cost-effective ingredients.