Petrochemicals Recycled Bottles 05-08-2021 - Arhive

Petrochemicals Recycled Bottles

Crude Oil Prices Trend

Call for better design of recycled plastic products / Need for harmonised rules with focus on mechanical recycling / Zero Waste Europe paper

NGO Zero Waste Europe is calling for a strong push towards circular design that prepares plastics for reuse and “environmentally sound” mechanical recycling. Published in July 2021, its position paper “Designing for real recycling, not plastic lock-in” says Europe cannot achieve a circular economy as outlined in its Circular Economy Action Plan without closing the gap between recyclability potential, actual collection and sorting, and recycling.

According to Zero Waste Europe, design improvements could halve the cost of recycling plastic packaging waste. It called for design-for-recycling standards for each product or material group rather than having broad overall principles that cannot be applied in practice, along with a shift to using fewer types of plastics. For packaging, this would ideally mean moving towards single polymers.

Smart illuminated panels and grills enable innovative designs while integrating sensors aimed at adas and autonomous driving

Marelli Automotive Lighting, the lighting division of leading global automotive supplier Marelli, and Samvardhana Motherson Automotive Systems Group (SMRP BV), one of the world’s largest manufacturers of interior and exterior components for the automotive industry, have signed a MOU (Memorandum of Understanding) to explore new technological partnership focused on Smart illuminated exterior body parts. This intends to focus on components such as front grills and bumpers, along with other car parts that can be illuminated. Petrochemicals Recycled Bottles

These components are expected to become a growing trend in the future of mobility, with increased adoption of Advanced Driver-Assistance Systems (ADAS) and Autonomous Driving (AD) in the coming years.

In the frame of the agreement, SMRP BV will contribute its strong expertise in the production of big plastic automotive parts through its operating subsidiaries, while Marelli Automotive Lighting will bring its extensive know-how in the field of automotive lighting and sensors integration to the collaboration respectively. The collaboration will be aimed at OEMs globally and will focus on Smart illuminated front grills and bumpers, as well as on illuminated rear ends, illuminated fenders and illuminated rocker panels.

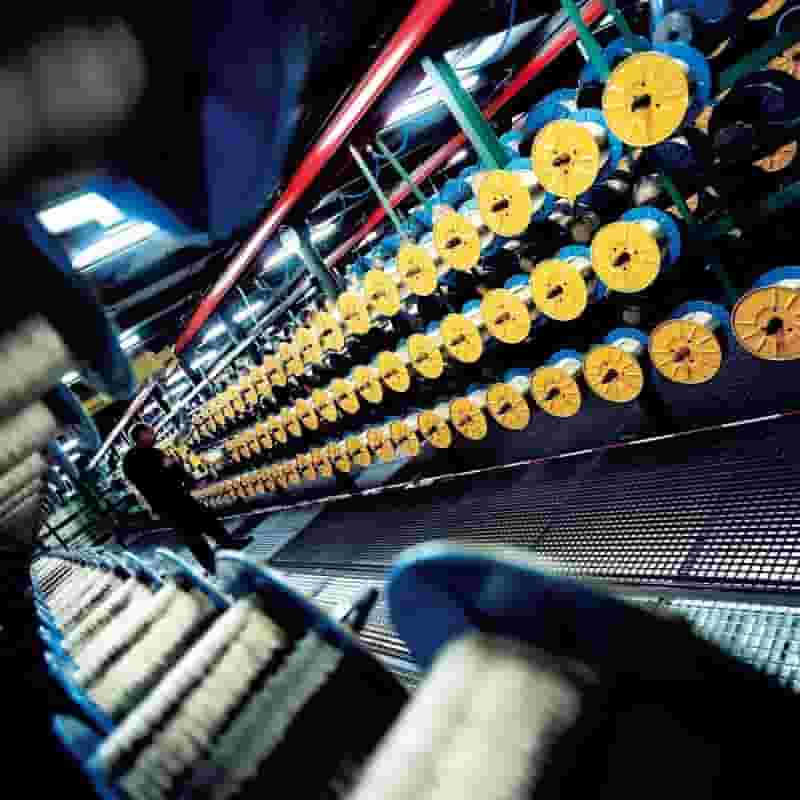

-Conti to “upcycle” PET bottles into tire reinforcement from 2022

Continental is to start reprocessing PET (polyethylene terephthalate) from recycled bottles into reinforcing fibres for use in its tires as of 2022, the company has announced.

The operation will employ PET recycling technology developed jointly with fibre specialist OTIZ, Oriental Industries (Suzhou) Ltd, according to a 3 Aug release from the German group. Petrochemicals Recycled Bottles

The mechanical process, it said, eliminates the need for intermediate chemical depolymerisation steps and can provide raw materials that match the quality of virgin PET.

“This can completely replace conventional polyester,” stated Continental, noting that the reinforcing yarn will be used in the construction of tire carcasses.

“As early as 2022, we will be able to use material obtained from recycled PET bottles in tire production,” said Dr. Andreas Topp, responsible for materials, process development and industrialization in Continental’s Tires business area.

In the “upcycling” process, “the fibres are spun from recycled PET without having to break the material down into its components beforehand,” added Topp.

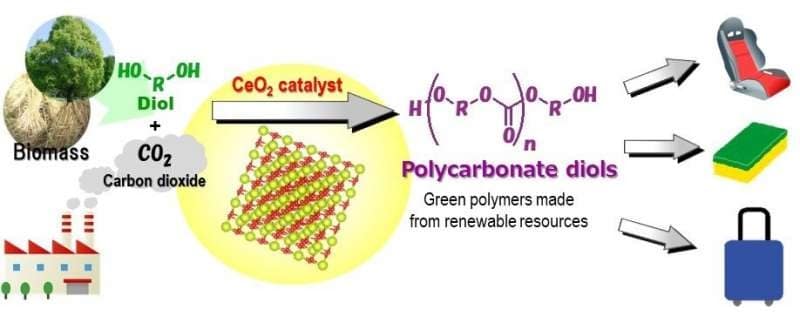

-World’s first ‘green’ synthesis of plastics from CO2

By combining a CeO2 catalyst with atmospheric carbon dioxide, researchers from Osaka City University, Tohoku University, and Nippon Steel Corporation have developed an effective catalytic process for the direct synthesis of polycarbonate diols without using dehydrating agents. Their method, published in Green Chemistry, does not rely on toxic chemical feedstock like phosgene and carbon monoxide, making it the world’s first high yield “green” reaction system.

There is a worldwide need to reduce carbon dioxide, one of the major greenhouse gases, and converting it into a useful chemical compound has attracted much attention in recent years. Petrochemicals Recycled Bottles

Various effective catalyst systems have been developed but they rely on toxic chemicals that churn out unmanageable by-products. Processes using substrates that are easily available and safe, with water as the only by-product, have emerged as an alternative. Yet, high levels of water by-product keep these processes from synthesizing enough polycarbonates.

-Nylon filament demand forecast in H2 2021: still cautious

Nylon filament market performance in the first 7 months of 2021 has been basically healthy. Even in the traditional slack season of June and July, only the conventional products appeared to be slack, while sales of the hot-sold products have never been dull. Petrochemicals Recycled Bottles

The peak season is coming closer, and part of downstream demand is expected to recover in late August. Before the peak season truly comes, we will review the supply and demand performance of nylon filament in the January-July 2021.

Supply: NFY and downstream plants’ run rate in slack season higher year on year

Nylon filament plants have been running at higher rates in 2021. In January-July 2021, the average operating rate of nylon filament yarn (NFY) plants has been assessed above 80%, 20.6 percentage point higher than the same period of 2020, and 9.5 percentage point higher than that of 2019. In comparison with polyester filament yarn plants, which has just recovered to the similar rate in 2019, while nylon has evidently grown higher than that of 2019.

-Hydrogen Plan Isn’t Very Green Under U.S. Infrastructure Deal

- Proposed legislation would create hydrogen hubs in gas regions

- Bill also would fund hydrogen produced via renewables, nuclear

Building a hydrogen-based energy system in the U.S., which some analysts call key to fighting climate change, would be based largely on fossil fuels under the bipartisan infrastructure bill heading for a Senate vote.

The legislation provides for $8 billion in spending to establish at least four “regional clean hydrogen hubs” producing and using the fuel for manufacturing, heating and transportation. At least two would be in U.S. regions “with the greatest natural gas resources,” according to the bill. One hub would demonstrate production from fossil fuels, one would use renewable power, and one would use nuclear power. Coal also is listed a potential source. Petrochemicals Recycled Bottles

-How much is the Pearlised BOPP Film industry worth worldwide?

Pearlised BOPP Film Market: An Overview

One of the most preferred polymers in food packaging and in printing application is polypropylene due to its excellent properties like high-temperature resistance, low moisture resistance, and high stiffness.

To improve mechanical properties, this film is stretched in both directions and across machine to form biaxially oriented polypropylene films (BOPP film). Fillers such as talc and calcium carbonate and pigments are added to BOPP film to provide a pearly aesthetic look and improve optical properties. Petrochemicals Recycled Bottles

Pearlised BOPP film finds application majorly in cold drink packaging such as ice cream packaging, biscuits, sweets, and flavour snack packaging. The advantage that pearlised BOPP film provides other films is it can be used as a monolayer for packaging or as a component of multilayer film suitable for overprinting.

The rapid increase in demand for flexible packaging solutions plays a crucial role in increasing demand for the pearlised BOPP film market. Pearlised BOPP film is Ultra Violet (UV) resistant provide excellent stability over the wide temperature range and high mechanical strength.

-Shortage of raw materials worries insulation manufacturer / Next price increase on the horizon?

Citing a worsening shortage of raw materials, insulation manufacturer Armacell (Capellen / Luxembourg; www.armacell.com) is playing offense: raw material and operating costs have “risen dramatically” in the past few months, the company writes, attributing this to high global demand for many commodities, combined with hoarding purchases. Petrochemicals Recycled Bottles

“The construction industry as a whole and we as insulation manufacturers are under enormous price pressure. All types of plastics are affected by these drastic price surges,” explains Guillerme Huguen, the company’s head of purchasing and chief strategist. It does not seem out of question that Armacell will raise its prices again as a result: “With the prices for our raw materials, operating supplies, energy and logistics services continuing to rise, our options are limited in this extremely tense market situation,” adds Huguen, leaving more than one loophole open.

In May 2021, the manufacturer of flexible insulation materials for plant insulation and technical foams had already increased the prices for its entire product range by 7.3% and explained this measure with the increased raw material and operating costs.

-How Does The Need For Packaging Drive The Xylene Industry?

The increasing demand for paraxylene across the globe contributes to the growth of the xylene market. Paraxylene is one of the isomers of xylene and is essential in the production of polyethylene terephthalate (PET).

PET is used in industries such as beverage packaging, consumer goods, sheets & films, food packaging, automotive, and construction. The increase in the need for packaging material has increased the demand for PET and hence contributes to the growth of the paraxylene market. Petrochemicals Recycled Bottles

To meet the increasing demand for paraxylene, new production plants have been set up. For instance, in 2019, Formosa Chemicals and Fibre Corp., a Taiwan-based manufacturer and marketer of chemical products, built a new production plant with the capacity to produce 900,000 mt/year of paraxylene, 640,000 mt/year of benzene and 240,000 mt/year of Orth xylene.

This new plant will support the demand for Xylene in South-east Asia. The growing demand for paraxylene thereby drives the xylene market.

-Eastman molecular recycling technologies to advance Procter & Gamble packaging goals

Innovative Eastman Renew materials reduce reliance on virgin plastic packaging

Today Eastman announced that it has entered an agreement with Procter & Gamble to further accelerate the transformation of plastic packaging and collaborate on recycling solutions to enable a circular economy.

P&G will use Eastman Renew materials in select products and packaging, supporting both companies’ goals to reduce the use of virgin plastic from fossil resources. Additionally, the companies will collaborate on advocacy initiatives aimed at reducing reliance on virgin plastic and enabling a circular economy for many products people depend on daily. Petrochemicals Recycled Bottles

“Eliminating waste plastic from our environment is a complex global challenge that requires a comprehensive, collaborative approach across the entire plastics lifecycle. P&G is taking a thoughtful approach to addressing the collection, processing, revitalization, and reuse of materials. That’s why we selected Eastman’s molecular recycling technologies which enable former waste to be transformed into useful products,” explained Lee Ellen Drechsler, Procter & Gamble Senior Vice President of R&D.

Petrochemicals Recycled Bottles