Petrochemicals – Recycled Resin – PET-bottle 11-07-2022 - Arhive

Petrochemicals – Recycled Resin – PET-bottle

Monoethyleneglycol-MEG – Petrochemicals

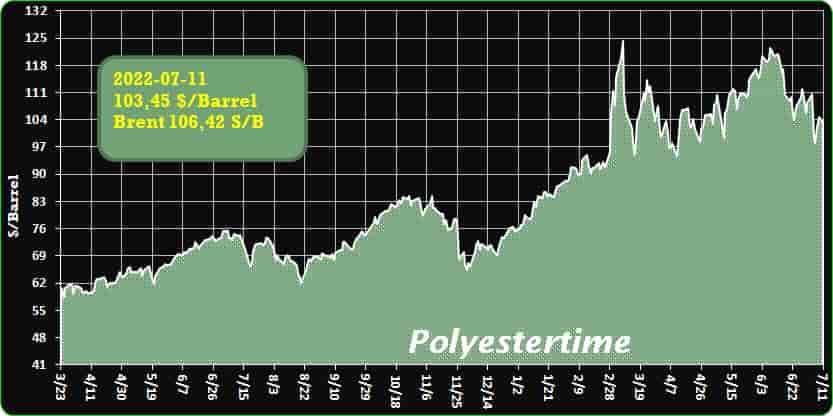

Crude Oil Prices Trend

-Faurecia to close French seat-frame plant

French supplier Faurecia said today that it plans to close a plant producing seat frames in eastern France, with the loss of 78 jobs.

The Nompatelize seat-frame factory will close at the end of the year, the company said in a statement.

Domestic vehicle production by French carmakers Renault and Faurecia’s parent, PSA/Peugeot-Citroen, has fallen 40 percent since 2007 to 1.5 million last year as demand for new cars slumped and manufacturers transferred assembly lines to lower-wage economies. Petrochemicals – Recycled Resin – PET-bottle

Over the past three years, the Nompatelize site has responded to falling sales with temporary layoffs and staff transfers to other Faurecia sites, the company said.

“The current levels of activity and forecasts are not sufficient to maintain operations in the face of ongoing losses,” the statement said.

-Demand for Recycled Resin to Outpace Supply

Report cites limitations in waste collection and recycling infrastructure.

Corporate sustainability goals and new legislation are driving increased demand for recycled plastics. Notably, a new California law targets a 30% recycling rate for single use plastics by 2028, increasing to 65% by 2032. However, the ambitious targets set by companies and governments may be beyond the reach of current recycling infrastructure.

An article by Paula Leardini, senior analyst at ICIS, describes the gap between current capacity and expected demand. ICIS estimates that in 2021 there were 53 million tons of input capacity for rPET, rPE, and rPP and that global recycle output reached 12% of global virgin consumption. Recycled content targets adopted by corporations and mandated by governments are generally far higher. Petrochemicals – Recycled Resin – PET-bottle

To estimate expected global demand, an ICIS model assumed a recycled content target of 50% by 2025 for PET, 25% by 2025 for PE and PP, and 35% by 2030 for PE and PP.

The model predicts that an annual growth rate of over 45% would be needed to reach recycled content rate targets by 2025. Leardini writes that at least 1800 new recycling plants with an average output of 27,500 tons per year would be necessary for PET alone. An annual growth rate of over 20% would be required to meet the targets for 2030, requiring 600 new recycling plants in each of the next nine years.

-Covestro’s focus on sustainable PU at K

Covestro will focus on its sustainability drive at K 2022 in October, following up on its recently announced collaboration with two petrochemical companies, Finland’s Neste and South Korea’s SK Geocentric, to supply mass-balanced benzene for MDI production in China.

The company had already committed to making TDI from renewable raw materials, including biomass, bio waste and residual materials, allocated to products using a mass-balance approach. This, it claims, generates no net CO2 from production “cradle” to the factory gate. Petrochemicals – Recycled Resin – PET-bottle

It is gradually converting production sites to the ISCC Plus sustainability standard. This is already in place at Leverkusen, Dormagen and Krefeld-Uerdigen in Germany; Antwerp, Belgium and Shanghai, China. Covestro has signed contracts with energy suppliers including Ørsted, EnBW, ENGIE and Datang Wuzhong New Energy, among others to supply these sites with electricity from renewable sources.

Covestro and its partners have developed a chemical recycling process to recover polyol and the precursor to TDI from PU mattress foam, with results at the pilot plant in Leverkusen said to be promising. The partner companies now intend to extend the project to the industrial processing of flexible foams.

The company is also a co-ordinator of the Circular Foam project. This EU initiative includes 22 partners from nine countries, dedicated to the chemical reprocessing of rigid PU from building insulation and used refrigerators.

The project aims to save up to 1 million metric tons of waste, and 2.9 million tonnes of CO2 emissions, annually in Europe by 2040. Petrochemicals – Recycled Resin – PET-bottle

-SAP and DIC to develop plastic tracing system using blockchain

The GreenToken by SAP blockchain solution will be used to track raw materials along the supply chain.

Japanese chemical company DIC Corporation (DIC) has partnered with application software firm SAP to develop a waste plastic traceability system to increase the recycling of plastic resources. Petrochemicals – Recycled Resin – PET-bottle

The pilot project will use GreenToken by SAP, a private blockchain solution, to track raw materials along the supply chain from the initial stage of material generation.

The process aims to improve the visibility of manufacturing and inspection processes, as well as that of data related to quality and physical properties.

GreenToken by SAP records information such as unique attributes related to the origin of raw materials, carbon footprint, the origin of collected polystyrene containers and sustainability certification data using tokens.

The digital twin technology allows materials to be tracked even if they are combined with other raw materials and processed into new products.

DIC packaging material products division executive officer and general manager Yuji Morinaga said: “Consumer awareness of the circular economy is high. This has increased demand for sustainable packaging.

“Our work with the GreenToken helps substantiate environmental claims and supports our mission to advance the recycling of plastics and build a closed-loop recycling system that employs chemical recycling.”

SAP developed GreenToken by SAP through its intrapreneurship programme.

The technology makes the supply chain transparent at all points, from origin to manufacture, sale, use, collection, pulverisation, recycling and reuse.

GreenToken by SAP co-founder James Veale said: “Our solution proves that it really is circular plastic and provides complete, auditable supply chain transparency.

“That means more trust in recycling from customers and ultimately less waste in the environment.”

DIC manufactures polystyrene, a polymer widely used in containers for food products and other applications. Petrochemicals – Recycled Resin – PET-bottle

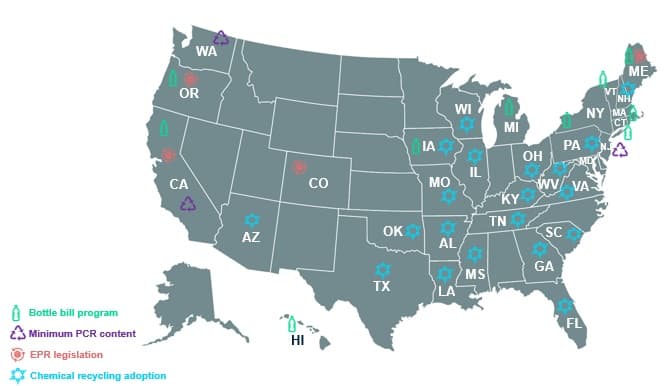

-Two US states pass supportive chemical recycling legislation

New Hampshire and Missouri have passed legislation supporting chemical recycling, bringing the total number of states with similar legislation to 20, with six bills having been passed since the start of 2022. Petrochemicals – Recycled Resin – PET-bottle

US PLASTICS AND RECYCLING SNAPSHOT

Under New Hampshire Senate Bill 367 and Missouri House Bill 2485, the legal definitions of chemical recycling processes such as pyrolysis, solvolysis and depolymerisation will be amended to no longer be categorised under “disposal” and “solid waste management facility”.

This would mean the investment, construction and running of chemical recycling facilities covered under these laws could grant them funding, taxation or environmental regulation as a recycling facility rather than as a waste to fuel or disposal facility.

Moreover, adopting the legal definition of recycling opens the door for chemically recycled material to be used in future post-consumer recycled (PCR) content mandates or as marketable recycled material.

Many chemical recycling technologies have existed for years, although companies have only recently commissioned production units.

Chemical recyclers estimate that it will take at least another seven to 10 years to reach true commercial scale. The bulk of the industry remains at pilot stage, with most prices being negotiated via tolling agreements. Petrochemicals – Recycled Resin – PET-bottle

While chemical recycling technology could provide complementary opportunities for plastic waste streams that are difficult to mechanically recycle, often chemical recycling facilities can utilise the same feedstocks as mechanical recyclers.

-MEG rebounds on further output contraction

MEG spot and futures prices increased Thursday on news of further output contraction after hovering low for a while.

Besides planned maintenance, some producers were inactive to keep the units running due to poor economics. Operating rate of MEG units in China is expected to fall to a quite low level in mid-August. Coal-based MEG plant operating rate is expected to fell to around 35% or even lower. Petrochemicals – Recycled Resin – PET-bottle

China domestic MEG supply will further decrease in July-August. Based on the estimation of 81%, 85% and 87% for polyester polymerization rate in July, August and September, total MEG inventory is expected to decrease by around 200kt.

However, MEG inventory remains high and the supply-demand structure remains weak. Meanwhile, a lot of MEG cargoes are expected to arrive in end-July. The upward momentum may weaken with the improvement of production margins.

-Kao uses chemically recycled PET material for the inner plate in foundation makeup

Beginning with the materials used to make the inner plate of the makeup brand media’s new powder foundation, the Kao Corporation is incorporating the use of chemically recycled PET (polyethylene terephthalate) material manufactured by PET Refine Technology Co., Ltd., a group company of JEPLAN Inc., using the chemical recycling technology* maintained by JEPLAN. Kao will progressively introduce chemically recycled PET materials starting in July of this year. Petrochemicals – Recycled Resin – PET-bottle

Through this initiative, Kao will reduce the amount of virgin plastic used in the makeup category of the Kao cosmetics business, promote sustainable manufacturing, and further promote efforts to realize horizontal recycling of plastic cosmetic containers.

Kao began using chemically recycled PET materials from the skin care product containers of the cosmetics brand Twany in June 2021, and has been gradually expanding their use to a number of brands. In collaboration with JEPLAN, Kao is also working on a horizontal recycling field test where used cosmetics bottles collected from customers at stores are turned into new plastic cosmetic bottles.

On the other hand, powder foundations have traditionally been able to be used by repeatedly refilling the compact case. Depending on the features of the product, the refill can be an inner plate made of virgin PET material or aluminum.

The inner plate, which is made of virgin PET material, will be gradually switched to chemically recycled PET material of the same quality. Kao continues to promote more environmentally friendly and sustainable manufacturing.

Petrochemicals – Recycled Resin – PET-bottle