Petrochemicals Recycled Styrenics Automotive 28-08-2021 - Arhive

Petrochemicals recycled styrenicss Automotive

Renewably Sourced Materials to Help Replace Petrochemicals in Apparel for a Healthier Planet

lululemon athletica inc. (NASDAQ:LULU) today announced a multi-year collaboration with sustainable materials leader Genomatica to bring renewably-sourced, bio-based materials into lululemon’s products. This represents lululemon’s first-ever equity investment in a sustainable materials company and Genomatica’s largest partnership within the retail industry. Together, the two companies will create a lower-impact, plant-based nylon to replace conventional nylon, which is the largest volume of synthetic material currently used to make lululemon products.

Genomatica uses biotechnology and fermentation to convert plant-based ingredients into widely used chemical building blocks, like those used to make nylon. These building blocks are converted to pellets and yarns, and the companies will be working closely with lululemon’s fabric supply chain to incorporate .this material into future products Through this collaboration, the companies seek to create positive change within the $22B global nylon market by building more sustainable supply chains.

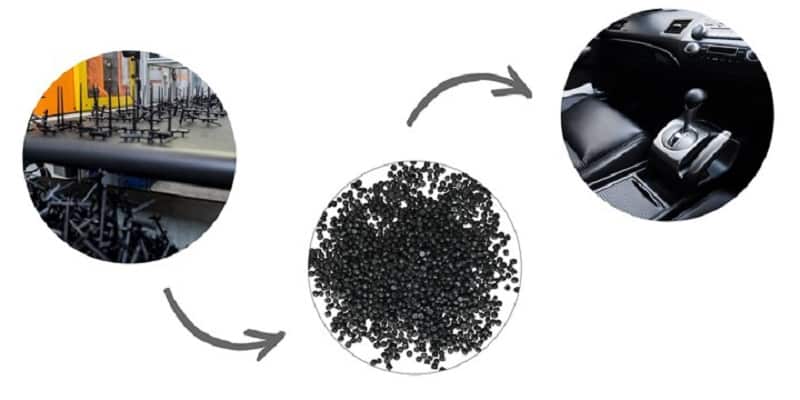

-TPE with Recycled Content for Automotive Interiors

Hexpol TPE’s has expanded its portfolio of Dryflex Circular TPE grades with recycled content. Petrochemicals recycled styrenicss Automotive

An expanded portfolio of TPEs with recycled content is now being offered by Hexpol TPE (U.S. office in Sandusky, Ohio). The new Dryflex Circular TPE grades have been tested for odor emissions performance in automotive interior applications such as inlay mats, cup holders, sealing lips and HVAC parts.

First launched in 2019, Dryflex Circular TPEs were developed to support the shift from finite fossil-based virgin materials. Recycled polymers from various sources, including PCR (post-consumer recyclate) and PIR (post-industrial recyclate), are incorporated into the Dryflex Circular TPEs. They can also be recycled in closed-loop systems at the end of life. An key aspect of automotive interior parts is their emission behaviour regarding odor and volatile substances.

Exhibits include first applications based on post-consumer recycled specialty styrenics materials Petrochemicals recycled styrenicss Automotive

INEOS Styrolution to exhibit in booth 16 at PIAE

Frankfurt, August 26, 2021 – INEOS Styrolution, the global leader in styrenics, will present the latest styrenics based automotive applications at the “Plastics in Automotive Engineering Conference” in Mannheim, Germany, on September 8 and 9. Exhibits will include automotive interior and exterior applications – as well as the first tests with recycled specialty styrenics materials.

Over the past years, INEOS Styrolution’s portfolio of specialty styrenics materials for the automotive industry has constantly grown. Today, the styrenics portfolio for the automotive industry includes specialty grades from the Novodur®, Novodur® High Heat, Luran® S and Terblend® product families.

-PKN Orlen plans with KBR to look at waste plastics to petchems recycling potential

Poland’s PKN Orlen has signed a letter of intent and a feasibility study contract with KBR with a view to processing waste plastics into liquid and gaseous products that can be used in the production of chemicals, monomers and polymers, said Biznespolska. Petrochemicals recycled styrenicss Automotive

State-controlled Orlen and technology and engineering services provider KBR would analyse the possibility of using KBR-licensed Hydro-PRT SM technology in the recycling and “circular economy” project, it added. The project would help Orlen achieve its target of becoming emissions neutral by 2050, the company said.

Orlen said that in Europe, 24.5mn tonnes of plastic waste are generated annually, with more than one-third recycled, 42% incinerated, and 24% landfilled.

The European Commission’s latest Green Deal proposals strengthen the importance of the bioeconomy Petrochemicals recycled styrenicss Automotive

The Bioeconomy is an important economic concept, relevant for the European Green Deal. How could the bioeconomy support the green transition? And what are the next steps in Brussels to make the circular and sustainable bioeconomy happen?

Already now, the circular and sustainable bioeconomy is contributing to all dimensions and objectives of the European Green Deal. Through the substitution of fossil-based products and materials and through carbon sequestration in soil and forests, together with its storage in harvested wood products, the bioeconomy can generate significant carbon savings to reduce the EU’s greenhouse gas emissions by at least 55% by 2030. At the same time, Europe has to make sure that the measures under the European Green Deal will be socially fair; no place and no person should be left behind. Again, the bioeconomy with its potential to create green jobs and growth in rural and coastal areas will mitigate this risk.

The European Commission’s latest Green Deal proposals strengthen the importance of the bioeconomy. The new Forest Strategy acknowledges and aims to boost the entire sustainable forest bioeconomy that works in synergy with the EU’s increased climate and biodiversity ambition.

-How to treat low price of VSF?

Cotton price has been increasing since the end of Jun as ZCE cotton futures has soared from 15,000yuan/mt to 18,500yuan/mt, gaining ground by 3,500yuan/mt in less than two months and the uptrend seems to sustain.

As for VSF, the performance is not eye-catching despite rising price amid minor increase of sales in early Jul. However, the market fails to keep strong after Zhengzhou was hit by heavy rain and the COVID-19 was spreading in Nanjing at the end of Jul. Sales seemed to slow down since then and the price failed to exceed 13,200yuan/mt. Petrochemicals recycled styrenicss Automotive

As cellulose staple fiber, VSF is indeed lower than cotton that has been hiking. The price gap has reached the peak without policy intervention and seems to widen further.

-Merlin Plastics is primed to collaborate on a closed loop for packaging

Founder Tony Moucachen is ready to work with the entire plastics supply chain to develop a sustainable circular economy Petrochemicals recycled styrenicss Automotive

The The Canada Plastics Pact (CPP), established this past spring, is part of the Ellen MacArthur Foundation’s Plastics Pact Network – the most ambitious action that has ever been taken by the global plastics industry to solve our worldwide plastic waste problem. For the first time, the CPP brings together the entire plastics industry supply chain in Canada – from producers to goods and packaging manufacturers and retailers, to collectors and recyclers – all with a shared vision of a circular economy for plastics in which all varieties stay in the economy and out of the environment.

Because the packaging stream accounts for nearly 50 percent of all plastic waste produced in Canada, it is the immediate focus of the CPP’s collective efforts. Initial goals, aiming for 2025, are to not only have significantly less plastic packaging in the system overall, but also to make it more sustainable for recyclers to recover the packaging that does remain in our system. (CPP), established this past spring, is part of the Ellen MacArthur Foundation’s Plastics Pact Network – the most ambitious action that has ever been taken by the global plastics industry to solve our worldwide plastic waste problem. For the first time, the CPP brings together the entire plastics industry supply chain in Canada – from producers to goods and packaging manufacturers and retailers, to collectors and recyclers – all with a shared vision of a circular economy for plastics in which all varieties stay in the economy and out of the environment.

Because the packaging stream accounts for nearly 50 percent of all plastic waste produced in Canada, it is the immediate focus of the CPP’s collective efforts. Initial goals, aiming for 2025, are to not only have significantly less plastic packaging in the system overall, but also to make it more sustainable for recyclers to recover the packaging that does remain in our system.

-Conference on CO2-based Fuels and Chemicals 2022 – Call for Papers and Posters

Take the chance and submit your abstract for a presentation or poster now!

More than 200 leading international experts in Carbon Capture and Carbon Utilisation (Power-to-X) together with 20 exhibitors are expected to attend the hybrid event on 23–24 March 2022, in Cologne, Germany (www.co2-chemistry.eu). Main topics of the conference are strategy & policy in CCU, renewable energy and green hydrogen production, carbon capture technologies, CO2-based fuels for transport and aviation, CO2-based building blocks, bulk and fine chemicals as well as advanced CCU technologies. Petrochemicals recycled styrenicss Automotive

Visuals and PDF file in English available at: www.nova-institute.eu/press/?id=284

Carbon Capture and Utilisation (CCU) is one essential pillar for the supply of renewable carbon besides biomass utilisation and recycling. The transition to the direct use of CO2 as one alternative carbon source is needed as a key element to substitute fossil sources, to fight climate change and to shift towards sustainable and climate-friendly production and consumption. For providing the full benefits of CCU technologies the use of renewable energy is indispensable. Especially the supply of green hydrogen is crucial for the production of CO2-based fuels for transportation and aviation as well as for bulk and fine chemicals.

-Lanxess’ FR, Glass-Reinforced Nylon 6 Selected for Lower Weight EV Battery Housings

A Durethan nylon 6 grade from Lanxess applied to a series production of Korean carmaker

New battery module housing for electric vehicles (EVs) featuring a halogen-free, flame-retardant and glass-fiber-reinforced nylon 6 from Lanxess has been adopted to series production of EV models launched this year by Korean auto parts specialist Infac. Petrochemicals recycled styrenicss Automotive

The battery housing uses Durethan BKV30FN04 to satisfy stringent mechanical and chemical property requirements for today’s EV components. The material is characterized by its excellent flame-retardant and electrical properties, excellent processability, and its enabling of integration of complex functions required for housing components, resulting in a smaller number of parts and a simplified assembly process as well as lighter weight.

-Kelheim to outline its circular approach at Dornbirn

Bavarian viscose speciality fibre manufacturer Kelheim Fibres will outline how it approaches the circular economy, from raw material to product design and ‘end of life’, at the upcoming Dornbirn GFC Webinar Week.

Kelheim, the world’s first viscose fibre producer with an EMAS-certified environmental management system, says it is constantly working to further improve every single one of these key sustainably aspects. Its speciality viscose fibres can be functionalized as required, which often saves further processing steps (such as dyeing or coating) as well as reducing the consumption of energy, water and chemicals. Petrochemicals recycled styrenicss Automotive

At the end of their product life, fibres from Kelheim are also completely biodegradable in a short time (according to OECD Test 301 B) and therefore contribute to the preservation of valuable habitats.

Petrochemicals recycled styrenicss Automotive

Petrochemicals H2 BioPolymers Polyester 27-08-2021