Petrochemicals RPET Circular Economy 23-08-2021 - Arhive

Petrochemicals RPET Circular Economy

Petrochemicals ACN Polyethyleneterephthalate Trend

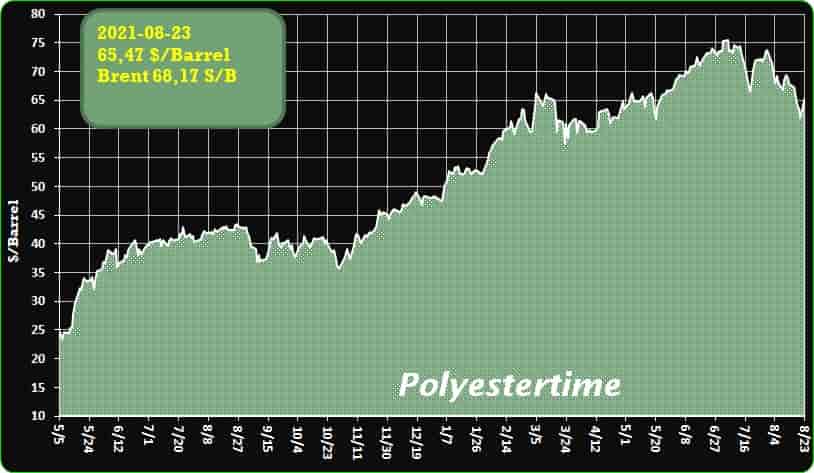

Crude Oil Prices Trend

-Commentary: Addressing plastics in the circular economy

Manufacturers and recyclers can move closer to achieving a circular economy for plastic scrap in several ways. Petrochemicals RPET Circular Economy

The circular economy can be defined as an ideal, zero-waste economy where the materials we use every day follow a closed-loop, circular journey that starts with manufacturing and utilization and then moves into reuse, repair, redistribute, refurbish, remanufacture and sometimes compost. With a circular economy, everything comes back and is used again in one form or another, minimizing or completely eliminating landfills and incineration.

The circular economy differs from the existing linear economy, where things are produced, used and then some things can be reused or recycled, but some things end up in the landfill, oceans or other places they don’t belong. Some types of plastics are especially problematic in terms of recycling, but increasingly, manufacturers are becoming more conscious of the materials they’re producing and using to ensure that they can either be recycled, reused or composted.

-Magna introduces new electric vehicle front end panel

The Mezzo panel integrates ADAS sensors and lighting and features hidden-until-lit functionality. Petrochemicals RPET Circular Economy

Canadian auto parts maker Magna International Inc. has introduced its new Mezzo panel technology, designed for electric vehicle front ends.

In a news release, Magna officials say the fully integrated Mezzo panel offers “a fresh canvas” for designers and an opportunity for engineers to integrate advanced driver assistance system (ADAS) capabilities like radar, cameras and lighting.

“We can essentially hand designers and engineers a paint brush to create adaptations of current vehicle designs or start fresh on a blank, customizable surface to redefine brands for future electric and autonomous vehicles,” said Brian Krull, global director of innovation for Magna’s Exteriors group.

-New needlepunch plant for Precision

Precision Textiles, a supplier of coated fabrics, nonwovens and laminations for the bedding, automotive and healthcare industries, is expanding its capacity with the opening of a new needlepunch plant in North Carolina.

The new 160,000-square-foot facility, once a textiles production plant that serviced the automobile industry, will help the company serve its customer base in the high-growth mattress industry. Petrochemicals RPET Circular Economy

Represents Precision’s first domestic manufacturing facility outside its New Jersey headquarters, the plant will double its needlepunch nonwovens production and boost its high-loft quilting fibre output by 50%.

In addition to its production capacity, the facility includes warehousing space with the 100-person workforce including new employees as well as some experienced staff from the textiles company that previously operated the plant.

-Plants: Toyo awarded contract for Prime’s PP plant

Faurecia to buy 60% of lighting firm Hella; deal worth EUR6.8 bn

Japanese engineering firm Toyo Engineering Corporation has been awarded a contract for a project to construct a polypropylene (PP) plant for Prime Polymer Co. As part of the deal, Toyo will carry out the EPC contract on a full turn-key basis that includes engineering, procurement, and construction. Petrochemicals RPET Circular Economy

Toyo will build the 200,000 tonnes/year capacity PP unit at Ichihara-shi site at Chiba. The unit is scheduled for start up in 2024.

-DGTR recommends anti-dumping duty on polyester yarn from China, Indonesia and Vietnam

The directorate is an investigative arm of the commerce ministry, which probes dumping of goods, a significant increase in imports and subsidised imports from India’s trade partners. Petrochemicals RPET Circular Economy

The commerce ministry’s investigative arm DGTR has recommended the imposition of anti-dumping duty on polyester yarn – used in making fabric for garments and home furnishing – from China, Indonesia, and Vietnam for five years, according to a notification.

The move is aimed at protecting domestic players in the sector against cheap imports from these countries.

The Directorate General of Trade Remedies (DGTR) has recommended the duty after concluding its probe that imports of the yarn from these countries have been exported at dumped prices in India, which has impacted the domestic industry.

-Inauguration of Plastics Recycling Association of Singapore (PRAS)

PRAS in partnership with HTP GmbH & Co and Aachen Germany is commencing the feasibility study of PET recycling plant in Singapore. PET is a large volume component of plastic waste in Singapore. Innovation is key to successful recycling of plastics. PRCOE (a subcommittee of PRAS) is envisioned to be a scientific knowledge and technology skills committee of PRAS and to be launched later as a R&D centre, for a range of plastics recycling strategies with desired sustainability credentials. PRCOE will co-learn from the leading centres around the world, and fast track and customise leading edge solutions to Singapore first and then to ASEAN as the companies foray into the region. Petrochemicals RPET Circular Economy

PRCOE signed a Memorandum of Understanding (MOU) with CHASE, Austria in the areas of digital twin technology, process intensification and circular process streams.

-Alpla acquires packaging manufacturer Wolf Plastics

The deal will expand packaging supplier Alpla’s product portfolio in Central and Southeastern Europe.

In a move that expands its product portfolio in Central and Southeastern Europe, packaging supplier Alpla Group is purchasing the Wolf Plastics Group for an undisclosed amount. Petrochemicals RPET Circular Economy

Headquartered in Kammern, Austria, Wolf also has production facilities in Hungary and Romania.

The Austrian and Romanian competition authorities are currently examining the proposal, Alpla officials said in a news release. Closure of the deal is subject to regulatory approval.

Besides digitalisation and automation, the circular economy is a key topic in the plastics processing industry. Changing from a linear to a circular economy, the quality of the recycled material plays an increasingly important role. Lindner, one of the leading manufacturers of shredders, system solutions and industrial washing systems for plastics recycling, is taking on this challenge and will be presenting a new hot-wash system for recovering PET (polyethylene terephthalate) at Fakuma 2021, booth A6-6108. Equipped with the new hot-wash tower and the also new Lindner step dryer, the company is setting new standards in PET recycling. When shredding the plastic to be recovered, the focus of Lindner’s Micromat series is firmly on quality, reliability, robustness and experience. Petrochemicals RPET Circular Economy

The circular economy remains a hot topic. Sustainability, resource conservation and the reduction of the ecological footprint take centre stage and underline the necessity of recycling all kinds of plastics. In addition to efficiency and cost-effectiveness, the main challenge is to use a reliably functioning system that allows for a high degree of flake purity and therefore high-quality recyclate.

-Lanxess Develops Concept for Automotive Radar Sensors with Integrated Thermal Management

The combination of thermally conductive plastics with metallic cooling elements will benefit radar sensors that enable driver-assistance systems.

Thermoplastic high-performance polymer supplier Lanxess has developed a new concept for radar sensors with integrated thermal management that will benefit autonomous driving. Petrochemicals RPET Circular Economy

Though there is still some distance to go, driver-assistance systems are increasingly set to become a key feature of future generations of cars, and 360° monitoring of the vehicle’s surroundings is enabled by — among other things — radar waves. The radar sensors are an essential component for distance control, lane change monitoring, collision avoidance, and blind-spot monitoring systems.

The sensors must be dust- and water-proof and consequently are designed as fully enclosed systems. However, this makes it difficult for heat to be effectively dissipated from the inside, which, in turn, can impair the performance of the electronics and durability of the sensors. “This is why we developed a concept that allows heat to be dissipated by means of thermally conductive plastics in combination with metallic cooling elements,” says Gregor Jaschkewitz, application developer in the High Performance Materials (HPM) business unit at Lanxess. “The individual sensor components are assembled using integrated snap fits and hot rivets, a process that is much less costly and time-consuming than using screws.”

Petrochemicals RPET Circular Economy